Mashine ya godoro ya mbao iliyoshinikizwa

Mashine ya kutengeneza godoro ya mbao iliyoumbwa inauzwa

Mashine ya godoro ya mbao iliyoshinikizwa

Mashine ya kutengeneza godoro ya mbao iliyoumbwa inauzwa

Vipengele kwa Mtazamo

Jedwali la Yaliyomo

Mashine ya pallet ya mbao iliyoshinikizwa ni vifaa maalum kwa ajili ya kutengeneza pallet za mbao zilizoshinikizwa. Inabadilisha nyuzi za mbao zilizotumika, vumbi la mbao, vipande vya mbao, mkaa wa mbao, maganda ya mpunga, n.k. kuwa pallet zenye nguvu na rafiki kwa mazingira kupitia mchakato wa mgandamizo wa shinikizo la juu.

Mashine hutumia joto na shinikizo kwa malighafi na kuziunganisha kwa kutumia adhesives asili au resini. Inaweza kutoa pallets za mbao 120-144 kwa siku ya masaa 16.

Mashine ya godoro ya mbao iliyotengenezwa huzalisha pallets za mbao zilizoshinikizwa na uwezo wa juu wa mzigo, uimara, unyevu na upinzani wa wadudu.

Zinagharimu, zinaweza kutumika tena na kukuza mazoea endelevu kwa kutumia nyenzo taka za kuni.

Kwa hivyo, inatumika sana katika tasnia ya vifaa, ghala na usafirishaji, ni mali ya lazima kwa kampuni zinazotafuta suluhisho bora na rafiki wa mazingira.

Aina za mashine za godoro za mbao zilizoshinikizwa zinazouzwa

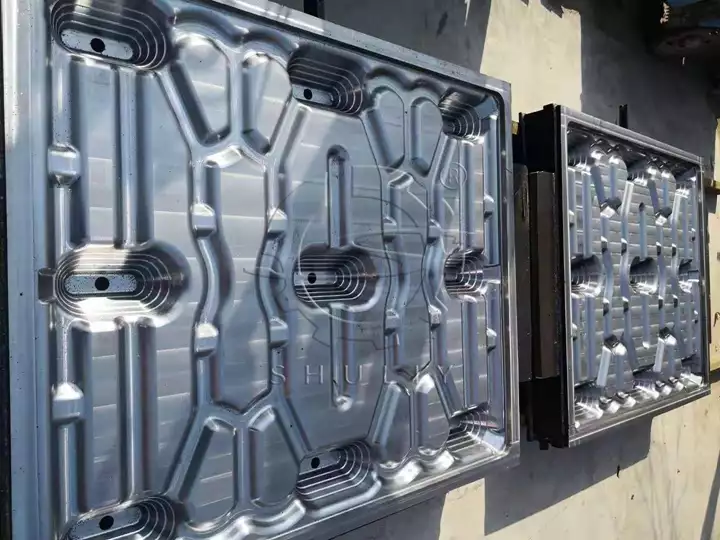

Kuna aina kadhaa za mashine za godoro za mbao zilizoshinikizwa zinazopatikana kwa kuuzwa sokoni. Shuliy's ina aina iliyoonyeshwa kwenye picha hapo juu.

- Mashine ya mtu binafsi ina ukungu tofauti na inaweza kutoa pallet za mbao 120-144 kwa siku ya masaa 16.

- Mashine iliyoonyeshwa upande wa kulia, kwa upande mwingine, ina molds ambayo inaweza kubadilishwa moja kwa moja, mara mbili ya ufanisi wa molds tofauti.

Kwa hivyo, kila aina inakidhi mahitaji tofauti ya uzalishaji na wateja wanaweza kuchagua kulingana na mahitaji yao mahususi na vikwazo vya bajeti.

Nguvu za mashine ya kutengeneza godoro ya mbao iliyoshinikizwa

- Rafiki wa mazingira: Hutumia nyuzi taka za kuni ili kukuza maendeleo endelevu.

- Gharama nafuu: Hupunguza gharama za nyenzo ikilinganishwa na pallets za jadi.

- Uwezo mkubwa wa uzalishaji: Pallets za kiasi kikubwa zinaweza kuzalishwa kwa ufanisi.

- Inadumu: Huzalisha pallets imara kwa mizigo mizito na utunzaji mbaya.

- Rahisi kufanya kazi: Kiolesura cha mtumiaji-kirafiki na uendeshaji rahisi.

- Kupunguza taka: Hupunguza upotevu kwa kutumia ipasavyo nyenzo za ziada za mbao.

- Inaweza kubinafsishwa: Pallet molds inaweza kuundwa kwa aina mbalimbali za ukubwa na miundo kulingana na mahitaji yako.

Malighafi ya kutengeneza pallet za mbao zilizoshinikizwa

Nyenzo zinazotumiwa kutengeneza pallet za mbao zilizoshinikizwa kwa kawaida hujumuisha nyuzi za mbao zilizotumika, vumbi la mbao, vipande vya mbao, maganda ya mpunga na mabaki mengine ya mbao.

Nyenzo hizi huchakatwa na kubanwa kwa kutumia mashine zenye shinikizo la juu na viungio ili kuunda godoro la mwisho la kuni lililoshinikwa.

Faida za pallets za mbao

- Kwanza, pallet za mbao ni za gharama nafuu ikilinganishwa na vifaa vingine kama vile pallet za plastiki au chuma.

- Pili, pallet za mbao ni rahisi kutengeneza na kusaga tena, kupunguza taka na kukuza uendelevu.

- Pia wana uwezo mzuri wa kubeba mizigo kwa mizigo mizito au isiyo ya kawaida.

- Pallet za mbao zinapatikana kwa urahisi na zinaweza kubinafsishwa ili kukidhi mahitaji maalum.

- Kwa kuongeza, wana mtego wa asili ambao hupunguza hatari ya kupungua kwa mzigo wakati wa upakiaji, upakiaji na usafirishaji.

Uwezo mwingi, kuegemea na urahisi wa kushughulikia pallet za mbao zimewafanya kuwa chaguo bora zaidi kwa usafirishaji, uhifadhi na utunzaji wa bidhaa ulimwenguni.

Molds kwa Shuliy taabu mbao godoro mashine

Mashine ya godoro ya mbao iliyoshinikizwa ya Shuliy inaweza kutoa pallet za plastiki na pallet za mbao.

Molds zimeundwa ili kukidhi mahitaji mbalimbali ya uzalishaji na kutoa matokeo bora, na kufanya mashine ya pallet ya mbao ya Shuliy kuwa chaguo la kuaminika kwa makampuni ambayo yanahitaji ufumbuzi wa ufanisi na wa kuaminika wa utengenezaji wa pallet.

Kanuni ya kazi ya mashine ya godoro ya mbao iliyoumbwa

Kanuni ya kazi ya mashine ya pallet ya Shuliy iliyoshinikwa inahusisha joto la juu na shinikizo.

Mashine hutumia joto na shinikizo kwa malighafi kama vile nyuzi taka za kuni na vumbi la mbao ndani ya shimo la ukungu.

Chini ya hali ya joto la juu na shinikizo, malighafi husisitizwa na kuumbwa kwa sura inayotaka ya godoro la mbao.

Mchanganyiko wa joto na shinikizo husaidia nyuzi za kuni kushikamana pamoja na kuunda godoro kali na la kudumu.

Mchakato huo unahakikisha kwamba pallets zinazozalishwa ni zenye nguvu, za kudumu na zinazostahimili unyevu, na kuzifanya zinafaa kwa matumizi mbalimbali ya viwanda.

Mtengenezaji wa mashine ya godoro ya mbao iliyoshinikizwa

Shuliy, kama mtengenezaji wa mashine ya godoro ya mbao iliyoshinikizwa, ni kampuni inayojishughulisha na kubuni, uzalishaji na uuzaji wa mashine za kutengeneza godoro za mbao zilizoshinikizwa.

Mashine zetu ni bora kwa upande wa bei, utendaji, na ubora, na huchukua jukumu muhimu katika kukuza mazoea endelevu kwa kutoa suluhisho bora na za gharama nafuu kwa ajili ya uzalishaji wa pallet za mbao zilizoshinikizwa zinazotumiwa katika tasnia kama vile usafirishaji, ghala, na usafirishaji.

Kando na hilo, pia tuna mashine ya kutengeneza vitalu vya pallet za mbao, mashine ya kuchuna mbao, mashine ya kusaga mbao, mashine ya kukata mbao, n.k. Ikiwa una nia, wasiliana nasi mara moja!

Vigezo vya kiufundi vya mashine ya godoro iliyoshinikizwa ya Shuliy

| Mfano | SL-800 |

| Shinikizo | Tani 800 |

| Kipenyo cha silinda ya mafuta ya haidrauli | 320 |

| Kiasi cha silinda ya mafuta ya haidrauli | 4 pcs |

| Njia ya kulisha | Kulisha mwongozo |

| Kuinua silinda ya mafuta | Kipenyo 100*2 |

| Joto inayopasha joto | digrii 150 |

| Injini kuu | 7.5kw |

| Uzito wa palati | 850kg/mita za ujazo |

| Uwezo | 120-144pcs kwa siku(saa 16) |

| Wakati wa shinikizo ya kutosha | Sekunde 35 |

| Wakati wa kipande moja | Sekunde 450 |

| Ukubwa wa godoro | Ukubwa wa godoro chini ya 1300*1250mm(unaweza kutengeneza herufi 2-3 kwenye ukungu) |

| Uzito | 14500kg |

| Dimension | 2300*1300*4300mm |

Mstari wa uzalishaji wa pallet za mbao zilizobandikwa

Mstari wa uzalishaji wa paleti za mbao zilizoshinikizwa ni mstari wa moja kwa moja…

Bidhaa Moto

Kifaa cha kuinua tanuru ya makaa ya chuma kwa mti wa kuni, makaa ya mti wa bamboo

Tanuru ya kuongeza kaboni ina uwezo wa kuweka kaboni magogo,…

Mashine ya kufunga filamu ya kupunguza joto kwa ajili ya makapi ya makaa ya kuchoma

Mashine ya kufungashia briketi za mkaa, kwa kweli joto hupungua...

Kikaango cha joto cha mviringo kwa utengenezaji wa makaa ya mti

Tanuri ya usawa ya kabonizesheni hutumika kubadilisha mbao…

Mashine ya kuondoa gome la mti kwa ajili ya kuondoa gome la mti

Logbåtsmaskinens avskärningsenhet är utformad för att effektivt och…

Mashine ya kusaga mbao kwa ajili ya kukata magogo

Mashine ya kukata mbao (sawmill) imeundwa kuchakata magogo…

Mashine ya kubana makaa ya shisha ya majimaji

Mashine hii ya kubana mkaa wa shisha ni kwa ufanisi…

Kiwanda cha makaa cha kuendelea kwa ajili ya kuuza

Tanuru inayoendelea ya uwekaji kaboni hutumiwa haswa kubadilisha…

Mashine ya pallet ya mbao iliyoshinikwa

Máy pallet gỗ nén dành cho sản xuất pallet gỗ nén…

Mashine ya kubandika makaa ya choma

Mashine ya kukandamiza mpira wa mkaa ya Shuliy ni ya kushinikiza...