Mstari wa uzalishaji wa vitalu vya mbao vya moja kwa moja

Mashine ya Kutengeneza Vitalu vya Mbao | Mashine ya kutengeneza vitalu vya mbao

Mstari wa uzalishaji wa vitalu vya mbao vya moja kwa moja

Mashine ya Kutengeneza Vitalu vya Mbao | Mashine ya kutengeneza vitalu vya mbao

Jedwali la Yaliyomo

Shuliy wood pallet block production line is used to convert biomass materials such as sawdust, wood chips, wood shavings, etc. to create strong wooden pallet blocks through mixing, molding and cutting processes.

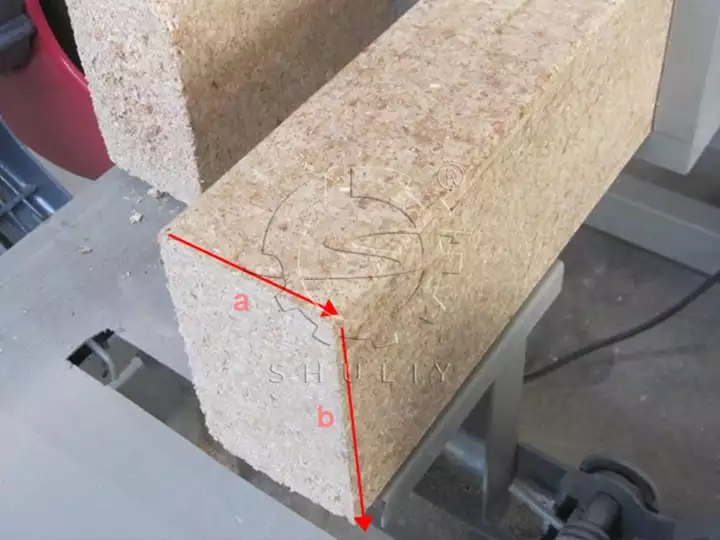

Vitalu vya godoro vya mbao vimeainishwa kama viwango vya kawaida (80*80mm, 90*90mm na 100*100mm) na viwango vya Ulaya (145*145mm, 145*100mm, nk).

Mstari huu wa uzalishaji wa godoro uliobanwa wa mbao una sifa za uwekaji otomatiki, ufanisi wa hali ya juu, na uwezo wa kubadilika. Kwa hivyo, ni suluhisho nzuri kwa kuchakata majani ili kupata faida.

Vipengele vya mstari wa uzalishaji wa vitalu vya mbao vya mbao vya mbao

- Kikamilifu kiotomatiki na kuokoa kazi. Laini nzima inadhibitiwa kimitambo na ina kiwango cha juu cha otomatiki, inayohitaji wafanyikazi wachache.

- Pato la 2-9m3saa 24. Mashine moja ya kutengeneza mbao inaweza kutumia mita 2-93 ya malighafi kwa siku, ambayo ina ufanisi mkubwa.

- Saizi na umbo la vitalu vya mbao vinavyoweza kubinafsishwa. Tuna ukubwa tofauti na maumbo kwa chaguo lako.

- Ukubwa wa kuzuia pallet ya mbao: kiwango cha kawaida (80 * 80mm, 90 * 90mm na 100 * 100mm) na kiwango cha Ulaya (145 * 145mm, 145 * 100mm, nk).

- Sura ya kuzuia pallet ya mbao: na shimo au bila shimo.

- Utumizi mpana wa malighafi. Nyenzo za majani kama vile machujo ya mbao, vipandikizi vya mbao, vipandikizi vya mbao, mianzi, nyuzinyuzi, vifuu vya nazi, n.k. vinaweza kutumika kutengeneza vitalu vya mbao.

- Huduma ya vitendo baada ya mauzo. Tunatoa huduma za usakinishaji kwenye tovuti, huduma ya mtandaoni ya saa 24, miongozo ya usakinishaji, na zaidi.

Mchakato wa kufanya kazi wa kutengeneza vitalu vya pallet ya mbao

The sawdust wood block making production line includes steps of wood chipping→sawdust making→sawdust drying→sawdsut and glue mixing→wood pallet blocks making→cutting. Now we take a closer look at the equipment used in each step, its function and its characteristics.

Upasuaji wa mbao

- Vifaa: kipiga ngoma

- Kazi: kata mbao za ukubwa wa taka ndani ya vipande vya mbao vyenye ukubwa unaofaa (25mm, vinavyoweza kurekebishwa).

- Sifa: kukata kwa ufanisi na sahihi ya kuni ili kutoa ukubwa sahihi wa kuni.

Utengenezaji wa vumbi

- Vifaa: kinu cha nyundo

- Kazi: Ponda vipande vya mbao ndani ya machujo ya sentimita 1 kwa sababu ya mahitaji ya kutengeneza mbao.

- Sifa: kusagwa sahihi ili kukidhi mahitaji yako.

Kukausha kwa vumbi

- Vifaa: rotary sawdust dryer

- Kazi: machujo ya mbao kavu ili kupunguza unyevu wake chini ya 10%.

- Sifa: joto linalofaa na wakati wa kukausha ili kuzuia kukausha kupita kiasi.

Mchanganyiko wa mbao na gundi

- Vifaa: mchanganyiko wa gundi

- Kazi: changanya sawdust na wambiso sawasawa ili iwe na viscosity fulani.

- Sifa: Kuchanganya sare ili kuhakikisha uthabiti wa kuni na wambiso.

Utengenezaji wa vitalu vya godoro vya mbao

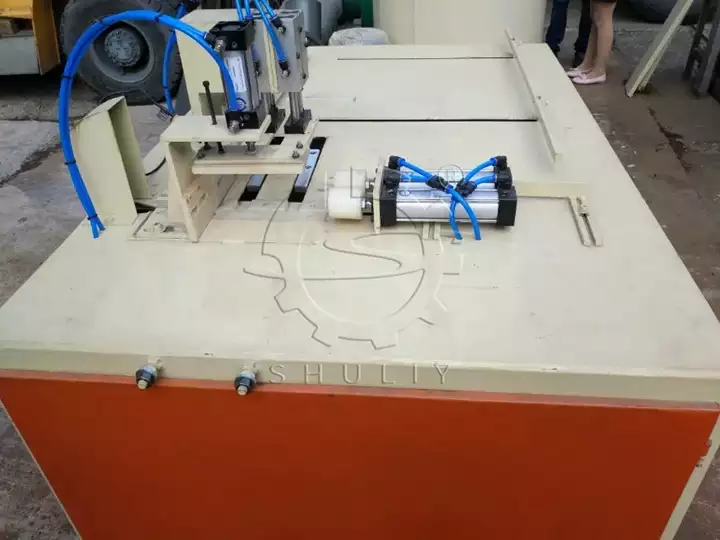

- Vifaa: mashine ya kutengeneza godoro ya mbao iliyoshinikizwa

- Kazi: bonyeza mbao zilizochanganywa kwenye vitalu vya ubora vya mbao.

- Sifa: joto la juu na shinikizo ili kuhakikisha wiani na utulivu wa vitalu.

Machujo ya mbao huzuia kukata

- Vifaa: mashine ya kukata

- Kazi: kata vitalu vya pallet ya mbao na urefu wa sare.

- Sifa: hakikisha bidhaa za mwisho na saizi zinazohitajika.

Mashine ya Shuliy: mtayarishaji na msambazaji wa laini ya godoro aliyeidhinishwa

Shuliy Machinery ni mzalishaji anayeheshimika na msambazaji wa mistari ya uzalishaji wa vitalu vya mbao. Ina faida zifuatazo:

- Kutoa ufumbuzi wa kuaminika. Kulingana na mahitaji yako, tunaweza kubuni suluhisho linalofaa zaidi ili kufaidisha biashara yako.

- Teknolojia ya kiwango cha juu na wafanyikazi wenye ujuzi. Tumekuwa kwenye tasnia kwa miongo kadhaa na tunabuni teknolojia yetu kila wakati. Pia tuna wafanyakazi wenye uzoefu ili kuhakikisha kuwa kila kipengele cha uzalishaji kinafikia viwango vya juu.

- Huduma ya kufikiria baada ya mauzo. Shuliy pia hutoa usakinishaji kwenye tovuti, mtandaoni ili kutatua matatizo, usaidizi wa video, nk.

- Huduma ya kuchukua na kuacha kwa ziara za kiwanda. Tunatoa huduma ya kuchukua na kushuka kwa wateja kutembelea kiwanda chetu na kushuhudia mchakato wetu wa uzalishaji na kiwango cha teknolojia.

- Upakiaji na usafirishaji wote kwa moja. Ubunifu huu hurahisisha sana mchakato wa usakinishaji na utumiaji, unaofaa sana kwa wateja.

Kwa nini kuwekeza katika uzalishaji wa vitalu vya mbao vya pallet?

Ufunguo wa kufanya uzalishaji wa pedi za pallet ni faida.

Vitalu vya pallet ya mbao vinafaa kwa mahitaji mbalimbali, kutoka kwa chakula hadi kemikali. Mahitaji ya soko ya vitalu vya godoro vya mbao yanaongezeka kwa kasi kutokana na sifa zao za urafiki wa mazingira.

Wanapendelewa na sekta nyingi kama vile vifaa, ghala, na usafirishaji.

Matumizi ya kuni ya taka hupunguza gharama na mstari wa uzalishaji wa vitalu vya mbao vya moja kwa moja hupunguza gharama za kazi. Asili yake ya urafiki wa mazingira huipa makali ya ushindani katika soko na huvutia wateja wanaojali mazingira.

Uzalishaji wa vitalu vya mbao vya mbao sio tu kukidhi soko, lakini pia hujenga faida na fursa za biashara zinazounga mkono ukuaji endelevu.

Kesi za kimataifa za onyesho la mstari wa uzalishaji wa godoro la mbao zilizoshinikizwa

Mstari wa uzalishaji wa godoro ulioshinikizwa wa Shuliy unatumika kote ulimwenguni na umeshinda uaminifu na sifa za wateja wengi. Tumesafirisha kwa nchi kadhaa, kama vile Thailand, Indonesia, nk.

Laini yetu husaidia biashara za ndani kutambua mabadiliko kutoka kwa kuni taka hadi bidhaa za thamani ya juu. Hii inaleta faida kubwa za kiuchumi.

Ikiwa una nia, karibu kuwasiliana nasi kwa maelezo zaidi ya mashine!

Wasiliana nasi kwa maelezo zaidi!

Are you looking for a wooden pallet block production line for biomass recycling?

Ikiwa ndio, wasiliana nasi na utuambie mahitaji yako, kama vile uwezo wa mashine, bajeti, n.k., meneja wetu mtaalamu atatoa suluhisho bora zaidi la kufaidisha biashara yako!

Mashine ya kutengeneza blok ya makaa kwa ajili ya blok za pallet za mbao

Maskin för tillverkning av träpallar är en specialiserad maskin…

Mashine ya kutengeneza blok za makaa ya mawe ya mbao na mashine ya kubana mkaa wa makaa ya mawe iliyotumwa Indonesia

Tumefanikiwa kushirikiana na mteja wa Indonesia kwa…

Bidhaa Moto

Mashine ya kuondoa gome la mti kwa ajili ya kuondoa gome la mti

Logbåtsmaskinens avskärningsenhet är utformad för att effektivt och…

Gari la gurudumu kwa kusaga na kuchanganya unga wa makaa

Mchanganyaji wa unga wa mkaa hutumika kuchanganya na…

Mashine ya kufunga mshipa kwa ajili ya kifaa cha shisha hookah

Máy đóng gói than shisha, thực ra đóng gói pillow…

Mashine ya kusaga mbao kwa ajili ya kukata magogo

Mashine ya kukata mbao (sawmill) imeundwa kuchakata magogo…

Mashine ya kufunga filamu ya kupunguza joto kwa ajili ya makapi ya makaa ya kuchoma

Mashine ya kufungashia briketi za mkaa, kwa kweli joto hupungua...

Kiwanda cha makaa cha kuendelea kwa ajili ya kuuza

Tanuru inayoendelea ya uwekaji kaboni hutumiwa haswa kubadilisha…

Kifaa cha kuinua tanuru ya makaa ya chuma kwa mti wa kuni, makaa ya mti wa bamboo

Tanuru ya kuongeza kaboni ina uwezo wa kuweka kaboni magogo,…

Kikaango cha joto cha mviringo kwa utengenezaji wa makaa ya mti

Tanuri ya usawa ya kabonizesheni hutumika kubadilisha mbao…

Mashine ya makaa ya hookah ya mzunguko kwa shisha ya mduara na ya mraba

Mashine ya mkaa ya rotary hookah ni maalum kwa…