Automatic wood pallet block production line

Wood Pallet Block Making Machine | Wood Block Making Machine

Automatic wood pallet block production line

Wood Pallet Block Making Machine | Wood Block Making Machine

Table of Contents

Shuliy wood pallet block production line is used to convert biomass materials such as sawdust, wood chips, wood shavings, etc. to create strong wooden pallet blocks through mixing, molding and cutting processes.

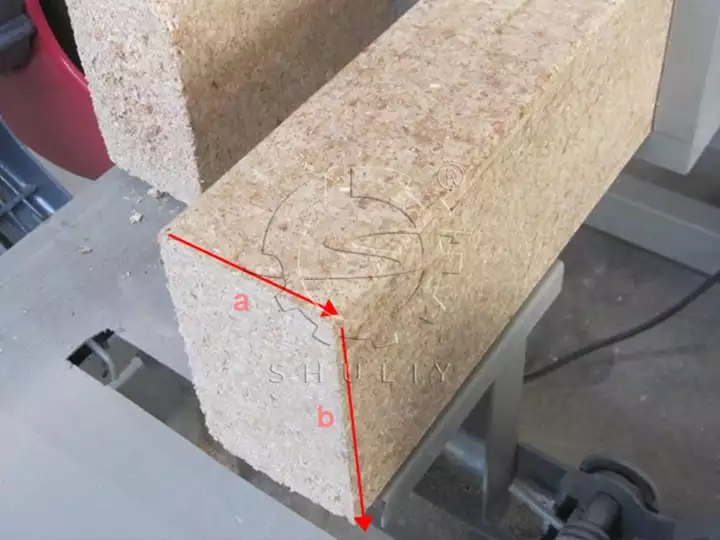

The wood pallet blocks are classified as the common standard(80*80mm, 90*90mm and 100*100mm) and the European standard(145*145mm, 145*100mm, etc).

This compressed wooden pallet block production line has features of automation, high efficiency, and strong adaptability. Thus, it’s a great solution for biomass recycling to make profits.

Features of sawdust wood pallet block production line

- Fully automatic and labor-saving. The entire line is mechanically controlled and has a high degree of automation, requiring less manpower.

- Output of 2-9m3/24h. One wood block making machine can use 2-9m3 of raw materials per day, which is highly efficient.

- Customizable wood pallet block size and shape. We have different sizes and shapes for your choice.

- Wooden pallet block size: common standard(80*80mm, 90*90mm and 100*100mm) and European standard(145*145mm, 145*100mm, etc).

- Wood pallet block shape: with a hole or without a hole.

- Wide applications of raw materials. Biomass materials such as sawdust, wood shavings, wood chips, bamboo, fiber, coconut shells, etc. can be used to produce wooden pallet blocks.

- Practical after-sales service. We offer on-site installation services, 24-hour online service, installation manuals, and more.

Working process of making wooden pallet blocks

The sawdust wood block making production line includes steps of wood chipping→sawdust making→sawdust drying→sawdsut and glue mixing→wood pallet blocks making→cutting. Now we take a closer look at the equipment used in each step, its function and its characteristics.

Wood chipping

- Equipment: drum wood chipper

- Function: cut large-sized waste wood into wood chips with suitable sizes(25mm, adjustable).

- Characteristics: efficient and accurate cutting of wood to provide the right size of wood.

Sawdust making

- Equipment: hammer mill

- Function: crush wood chips into 1cm sawdust because of wood blocks making requirements.

- Characteristics: accurate crushing to meet your needs.

Sawdust drying

- Equipment: rotary sawdust dryer

- Function: dry sawdust to reduce its moisture content below 10%.

- Characteristics: appropriate temperature and drying time to prevent over-drying.

Wood sawdust and glue mixing

- Equipment: glue mixer

- Function: mix the sawdust and adhesive evenly to make it have a certain viscosity.

- Characteristics: uniform mixing to ensure the consistency of wood and adhesive.

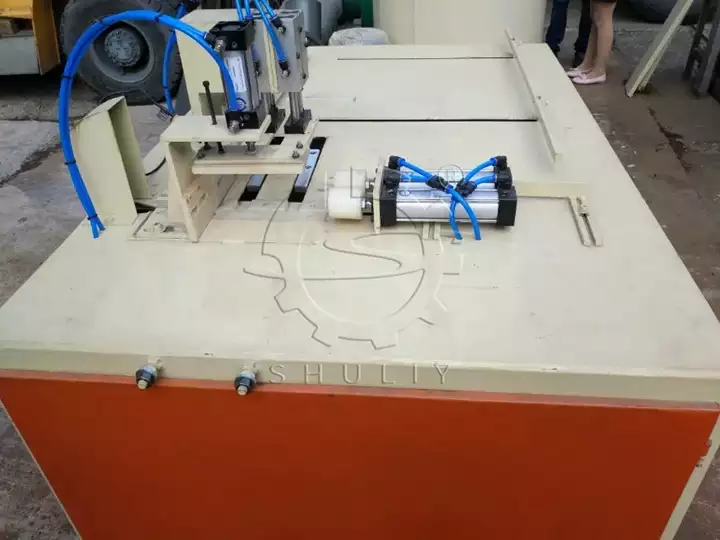

Wooden pallet blocks making

- Equipment: compressed wood pallet block making machine

- Function: press the mixed wood sawdust into quality wood blocks.

- Characteristics: high temperature and pressure to ensure the density and stability of the blocks.

Sawdust blocks cutting

- Equipment: cutter machine

- Function: cut wooden pallet blocks with uniform lengths.

- Characteristics: ensure the final products with the required sizes.

Shuliy Machinery: a credited pallet block line producer & supplier

Shuliy Machinery is a reputable producer and supplier of wood pallet block production lines. It has the following advantages:

- Provide reliable solutions. According to your needs, we can design the most suitable solution to benefit your business.

- Leading-edge technology and skilled employees. We have been in the industry for decades and are constantly innovating our technology. We also have an experienced workforce to ensure that every aspect of production meets high standards.

- Thoughtful after-sales service. Shuliy also provides on-site installation, online to solve problems, video support, etc.

- Pick-up and drop-off service for factory visits. We provide pick-up and drop-off service for customers to visit our factory and witness our production process and technology level.

- All-in-one loading and transportation. This design greatly simplifies the installation and use process, very convenient for customers.

Why invest in wooden pallet blocks production?

The key to conducting pallet pad production is profitability.

Wood pallet blocks are suitable for a wide range of needs, from food to chemicals. The market demand for wooden pallet blocks is steadily increasing due to their environmentally friendly features.

They’re favored by multiple sectors such as logistics, warehousing, and transportation.

The use of waste wood reduces costs and the automatic wood pallet block production line reduces labor costs. Its eco-friendly nature gives it a competitive edge in the market and attracts environmentally conscious customers.

Wooden pallet block production not only satisfies the market, but also creates profitability and business opportunities that support sustainable growth.

Global cases of compressed wood pallet block production line display

Shuliy compressed wood pallet block production line is widely used around the world and has won the trust and praise of many customers. We have exported to several countries, such as Thailand, Indonesia, etc.

Our line helps local enterprises to realize the transformation from waste wood to high-value products. This brings significant economic benefits.

If you’re interested, welcome to contact us for more machine details!

Contact us for more details!

Are you looking for a wooden pallet block production line for biomass recycling?

If yes, contact us and tell us your requirements, such as machine capacity, budget, etc., our professional manager will provide the best solution to profit your business!

Sawdust block making machine for wooden pallet blocks

The wood pallet block making machine is a specialized machine…

Sawdust block making machine helps Indonesian client profit

We have successfully cooperated with an Indonesian customer on a…

Hot Product

Flat die feed pellet machine for animal feed making

Feed pellet machine is designed to produce high-quality…

Roller log debarking machine for wood bark peeling

Log debarking machine is designed to efficiently and…

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Wood shaving machine for horse, chicken bedding

Wood shavings machine is designed to produce uniform…

Charcoal briquette making machine for coal plant

Charcoal briquette making machine is used to make…

Raymond mill for charcoal powder grinding

Raymond mill is to crush and grind charcoal…

Sawdust block making machine for wooden pallet blocks

The wood pallet block making machine is for…

Horizontal carbonization furnace for wood charcoal making

Horizontal carbonization furnace is used to convert wood…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually pillow packaging…