Tanuru ya mkaa inayoendelea inauzwa

Mashine ya Mkaa wa Nazi | Mashine ya Kutengeneza Mkaa wa Mpunga

Tanuru ya mkaa inayoendelea inauzwa

Mashine ya Mkaa wa Nazi | Mashine ya Kutengeneza Mkaa wa Mpunga

Vipengele kwa Mtazamo

Jedwali la Yaliyomo

Kontinuerlig karboniseringsovn er et effektivt og energieffektivt karboniseringsutstyr, som er spesielt brukt til å konvertere kokosnøttskall, risbåter osv til høykvalitets kull med en kapasitet på 800-1000kg/h.

Kwa kipengele chake cha kuendelea, tanuru ya mkaa inayoendelea hufanya mchakato wa uzalishaji wa mkaa kuwa laini na ufanisi zaidi.

Iwe unajishughulisha na uzalishaji wa mkaa au utumiaji wa rasilimali rafiki kwa mazingira, mashine ya kutengeneza mkaa itakuwa chaguo lako bora ili kukupa ufanisi endelevu na thabiti wa uzalishaji na mkaa uliokamilishwa wa hali ya juu.

Malighafi kwa ajili ya tanuru ya kaboni ya Shuliy inayoendelea

Aina hii ya tanuru ya kaboni inafaa kwa kaboni ya aina nyingi za malighafi ya majani, ikiwa ni pamoja na:

Risbåter, kokosnøtt-skall, palmeskall, peanøttskall, sagmugg, nøtteskall, maisstengel, bagasse, tregrener, bambusflis, sorgum-stengel, solsikkeskall, vintørr, maiskjerner, aprikos-skall, kaffebøt, bomulls-stengler, bønne-stengler, taro-gras, visne blader, kinesisk urtemygg, hamp-stengler, et al.

Nyenzo za punjepunje na kipenyo cha chini ya 10 cm zinaweza kuwa kaboni.

I tillegg kan kontinuerlig karboniseringsovn også behandle andre materialer med biomasseegenskaper, som elektronisk avfall, bokser, avfallsledninger, slam, husholdningsavfall, etc., for effektiv utnyttelse av disse ressursene og fremme bærekraftig utvikling.

Vipengele vya mashine ya mkaa wa nazi

- Uwezo wa kaboni 800-1000kg / h: Tanuru inayoendelea ya uwekaji kaboni inaweza kukamilisha mchakato wa kaboni ya kuni kwa wakati mmoja, na ufanisi wa ukaa unaboreshwa sana.

- Ulinzi wa mazingira: Mashine ya kutengeneza makaa ya maganda ya mchele hutumia teknolojia ya hali ya juu ya kudhibiti oksijeni, na utoaji wa gesi wakati wa mchakato wa uchomaji unadhibitiwa ipasavyo, ili kufikia athari za ulinzi wa mazingira.

- Uendeshaji rahisi: Uendeshaji wa tanuru ya kaboni inayoendelea ni rahisi sana, tu haja ya kuweka malighafi ndani ya tanuru na kuwasha vifaa.

- Teknolojia ya udhibiti wa hali ya juu: Tanuru ya kaboni inayoendelea inaweza kudhibiti kwa usahihi joto na wakati wa kaboni, ambayo hufanya utulivu wake kuwa mzuri sana.

- Kutumika kwa upana: Tanuru inayoendelea ya kuchoma inafaa kwa ganda la nazi, maganda ya mchele, vumbi la mbao, mbao laini, mianzi na kadhalika.

Vigezo vya kiufundi vya mashine inayoendelea ya kaboni

| Mfano | SL-800 | SL-1000 | SL-1200 |

| Kipenyo(mm) | 800 | 1000 | 1200 |

| Uwezo (kg/h) | 400-600 | 800-1000 | 1200-1500 |

| Nguvu kuu (kw) | 18.5 | 18.5 | 20 |

| Halijoto ya Ukaa (℃) | 500-800 | 500-800 | 500-800 |

| Nguvu ya Mashabiki(kw) | 5.5 | 5.5 | 5.5 |

Katika hapo juu, uwezo unajulikana kwa pato, na malisho ni kulingana na mvuto maalum wa malighafi. Na mchakato mzima wa carbonization huchukua 20-25min.

Kwa kuzingatia mambo haya yote kwa pamoja, basi unaweza kuchagua tanuru ya mkaa inayofaa zaidi kwa mahitaji ya biashara yako.

Matumizi ya mashine ya kutengeneza makaa ya mchele

- Uzalishaji wa mkaa: Tanuru inayoendelea ya uwekaji kaboni hutumiwa sana katika uzalishaji wa mkaa, ambayo inaweza kuboresha kwa kiasi kikubwa ufanisi wa ukaa, kupunguza matumizi ya nishati na kupunguza gharama za uzalishaji.

- Matibabu ya mabaki ya mazao: Matibabu ya mabaki ya mazao yamekuwa ni tatizo gumu kila mara, tanuru inayoendelea ya uwekaji kaboni inaweza kutibu kwa ufanisi mabaki ya mazao na kuyageuza kuwa rasilimali muhimu.

- Uzalishaji wa nishati ya majani: Uzalishaji wa nishati ya mimea pia ni uwanja muhimu wa matumizi ya tanuru ya kuendelea ya kaboni. Kwa kuweka kaboni nyenzo za biomasi, zinaweza kubadilishwa kuwa mafuta muhimu

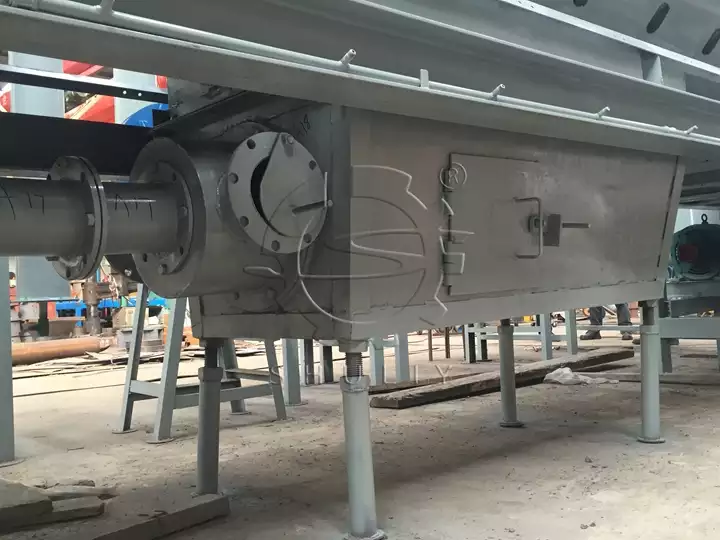

Muundo wa tanuru ya kaboni inayoendelea

Muundo wa tanuru ya mkaa inayoendelea imeundwa vizuri, hasa linajumuisha mfumo wa kulisha, mwili wa tanuru ya mkaa, mfumo wa joto, mfumo wa udhibiti na mfumo wa kutokwa.

| S/N | Jina la sehemu ya mashine | Kazi |

| 1 | Mfumo wa kulisha | kuwajibika kwa kuendelea kulisha malighafi kwenye tanuru ili kuhakikisha mwendelezo wa mchakato wa uzalishaji |

| 2 | Mwili wa tanuru ya kaboni | huweka halijoto sawa kupitia muundo wa sandwich ili kuleta kaboni malighafi |

| 3 | Mfumo wa joto | hutoa mazingira thabiti ya halijoto ya juu ili kukuza mmenyuko wa ukaa |

| 4 | Mfumo wa udhibiti | hufuatilia na kudhibiti mchakato wa uzalishaji kiotomatiki ili kuhakikisha usalama na ufanisi wa hali ya juu |

| 5 | Mfumo wa kutokwa | iliyo na kifaa cha kupoeza ili kuhakikisha pato la juu la mkaa uliomalizika |

Vipengele hivi kwa pamoja vinatambua uzalishaji mzuri na thabiti wa mkaa wa tanuru ya mkaa inayoendelea.

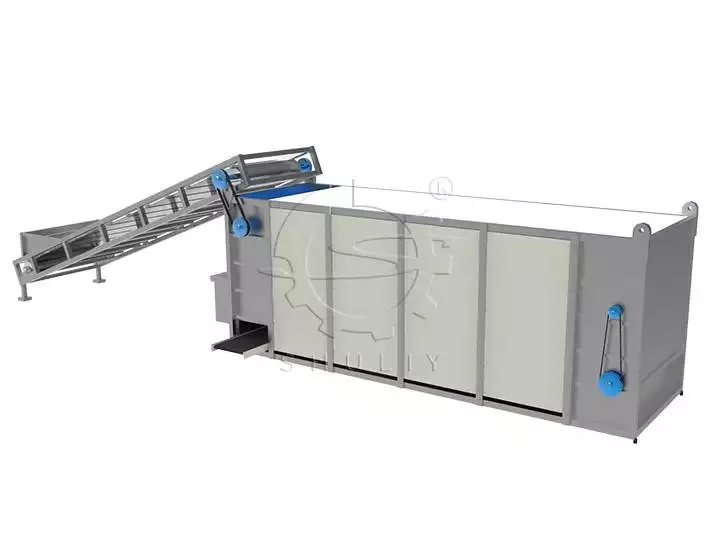

Vifaa Vinavyolingana vya tanuru ya uenezaji kaboni inayoendelea ya Shuliy

Kifaa cha kulisha

Mashine ya kaboniza inafaa kwa malighafi nzuri na lazima iwe na kifaa cha kulisha ili kuhakikisha kuwa malighafi huwekwa kila wakati kwenye tanuru, na hivyo kutambua mchakato mzuri wa uzalishaji wa kaboni.

Mfumo wa kuondoa vumbi la dawa ya maji

Aina za vichungi vya tanuru ya mkaa

Mchakato wa utengenezaji wa mkaa: jinsi ya kutengeneza mkaa?

Unapotaka kutengeneza mkaa, fuata hatua ifuatayo ili kukusaidia kutengeneza mkaa kwa mafanikio:

Maandalizi

Washa usalama wa gesi na subiri joto lipande hadi digrii 70.

Preheat

Anza kuwasha ili kuwasha moto kwa takriban saa moja.

Angalia moto wa bluu

Daima angalia moto wa bluu kwenye tanuru ili kubaini ikiwa umewashwa.

Nyenzo za kulisha

Wakati joto linafikia digrii 280, unaweza kuanza kulisha vifaa. Kulingana na vifaa tofauti, hali ya joto inapaswa kubadilishwa ipasavyo, kama vile majani karibu digrii 200.

Angalia na uzima moto

Angalia dimbwi la mwako, unaweza kuzima kichwa cha moto wakati kuna moto wazi, na utumie gesi inayozunguka inayowaka kuchoma na kuokoa nishati.

Utekelezaji

Bandari ya kutokwa ina vifaa vya condenser, ambayo ina athari ya baridi na inahakikisha kwamba makaa ya mawe yanayotoka ni kuhusu digrii 50, kuzuia kuwaka tena.

Mlolongo wa kazi hapo juu unahakikisha uendeshaji mzuri na salama wa tanuru ya kaboni inayoendelea, ambayo inafanya mchakato wa carbonization imara na kuokoa nishati, na wakati huo huo inakabiliana na mahitaji ya usindikaji wa vifaa tofauti.

Mambo yanayoathiri uchaguzi wa tanuru ya carbonizer inayoendelea

- Kwanza kabisa, ufanisi wa carbonization ni jambo la kuzingatia, na tanuru ya uwekaji kaboni yenye ufanisi mkubwa inaweza kuboresha ufanisi wa uzalishaji na kuongeza pato.

- Pili, ulinzi wa mazingira ni jambo ambalo haliwezi kupuuzwa, tanuru ya kaboni ya ubora inayoendelea inapaswa kuwa na uwezo wa kupunguza uchafuzi wa mazingira na kukidhi mahitaji ya maendeleo endelevu.

- Tatu, utulivu pia ni muhimu, operesheni thabiti inaweza kuhakikisha kuwa ubora na wingi wa mkaa unaozalishwa ni thabiti.

- Hatimaye, fikiria gharama ya matengenezo. Kuchagua tanuru ya mkaa yenye gharama ya chini ya matengenezo inaweza kupunguza matumizi ya uzalishaji wa biashara.

Jinsi ya kutumia tanuru ya kaboni kwenye mstari wa usindikaji wa mkaa?

Vår palm-kjerneskall kullmaskin brukes i kullproduksjonslinjer for å karbonisere ulike råmaterialer eller for å pini kay briquettes, tilsvarende forskjellige kullproduksjonslinjer.

Ni muhimu kuzingatia kwamba mchakato unaweza kutofautiana kidogo kulingana na aina na muundo wa tanuru ya kaboni na mahitaji maalum ya mstari wa uzalishaji wa mkaa, tafadhali wasiliana nasi kwa maelezo zaidi.

Kesi zilizofaulu za tanuru ya kaboni ya Shuliy inayoendelea

Shuliy kontinuerlig karboniseringsovn har hatt vellykkede installasjoner i ulike land, inkludert Storbritannia, Malaysia, Guinea og Ghana.

Matukio haya yanaonyesha matumizi mengi na kutegemewa kwa teknolojia yetu ya uongezaji kaboni katika maeneo na hali tofauti.

Usanifu wa hali ya juu na uendeshaji bora wa tanuru umetoa uzalishaji wa mkaa wa hali ya juu kila mara, na kuchangia katika ufumbuzi endelevu wa nishati na uhifadhi wa mazingira katika mataifa haya.

Maswali Yanayoulizwa Mara kwa Mara ya mashine ya mkaa wa nazi

Je, ni mahitaji gani ya unyevu wa malighafi? Je, ikiwa unyevu wa malighafi ni wa juu?

Unyevu wa malighafi unapaswa kuwa chini ya 20%. Ikiwa unyevu ni wa juu, inahitaji kukaushwa mapema na vifaa vya kukausha kwanza.

Ni nini mahitaji ya saizi ya malighafi?

Nyenzo yoyote chini ya sentimita 10 ni sawa.

Ni nyenzo gani zinazoweza kusindika na tanuru ya kaboni inayoendelea?

Tanuu za kaboni za Shuliy zinazoendelea zinaweza kushughulikia bati, karatasi za alumini, mikebe, takataka za nyumbani, plastiki, taka za kielektroniki, n.k. kando na majani.

Kikaango cha joto cha mviringo kwa utengenezaji wa makaa ya mti

Tanuri ya kabonishaji ya usawa, inayojulikana pia kama utengenezaji wa makaa ya kuni…

Kifaa cha kuinua tanuru ya makaa ya chuma kwa mti wa kuni, makaa ya mti wa bamboo

Tanuri ya kabonishaji yenye kuinua ina uwezo wa kukabonisha aina mbalimbali za…

Tres tipos de hornos de carbón en venta

Tanuri yetu ya makaa inachakata malighafi kama magogo ya kuni,…

¿Cómo hacer biocarbón valioso mediante la máquina de carbonización de biomasa?

Kubadilisha biomasi kuwa makaa ya thamani kupitia mashine ya kabonishaji ya biomasi…

Instalación exitosa de horno de carbonización SL-1200 en el Reino Unido

Habari njema kutoka Uingereza! Mteja wetu ameagiza SL-1200…

Enviar horno de carbón continuo a Zimbabue para obtener beneficios

Mnamo 2023, mteja wetu kutoka Zimbabwe alinunua tanuri moja ya makaa ya kuendelea…

¿Qué es el proceso de carbonización?

Kabonishaji ni mchakato wa kubadilisha malighafi za kikaboni kuwa vitu imara…

La máquina de hacer carbón Shuliy para la venta te ayuda a hacer carbón fácilmente

Katika dunia inayobadilika kila wakati, ulinzi wa mazingira na maendeleo endelevu yamekuwa muhimu…

¿Qué materiales pueden carbonizarse en el horno de carbón vertical?

Katika enzi ya kisasa ya viwanda, jinsi ya kukabonisha malighafi…

Línea de producción de carbón instalada por ingeniero en Indonesia

Tulifanikiwa kusafirisha seti ya vifaa vya mstari wa uzalishaji wa mkaa…

Bidhaa Moto

Mashine ya kukausha kwa mfululizo kwa makaa ya BBQ

Mashine ya kukausha mkaa wa mabriquette hutumika kwa BBQ…

Mashine ya kubandika makaa ya choma

Mashine ya kukandamiza mpira wa mkaa ya Shuliy ni ya kushinikiza...

Mashine ya kusaga mbao kwa ajili ya kukata magogo

Mashine ya kukata mbao (sawmill) imeundwa kuchakata magogo…

Mashine ya kufunga mshipa kwa ajili ya kifaa cha shisha hookah

Máy đóng gói than shisha, thực ra đóng gói pillow…

Mashine ya kuondoa gome la mti kwa ajili ya kuondoa gome la mti

Logbåtsmaskinens avskärningsenhet är utformad för att effektivt och…

Mashine ya kufunga filamu ya kupunguza joto kwa ajili ya makapi ya makaa ya kuchoma

Mashine ya kufungashia briketi za mkaa, kwa kweli joto hupungua...

Mashine ya kubana unga wa mbao kwa ajili ya kutengeneza briquettes za Pini Kay

Mashine ya briquette ya unga wa mbao (sawdust) hutumika kubana vipande vya mbao,…

Mashine ya kutengeneza makaa kwa kiwanda cha makaa

Máy làm viên than hoạt tính dùng để làm…

Kifaa cha kuinua tanuru ya makaa ya chuma kwa mti wa kuni, makaa ya mti wa bamboo

Tanuru ya kuongeza kaboni ina uwezo wa kuweka kaboni magogo,…