Sändning av biomassa briquette extruder till Bulgarien

Jedwali la Yaliyomo

Vår bulgariske kund driver ett träavfallsåtervinningsanläggning med omfattande erfarenhet av träbearbetning och återanvändning. Daglig produktion genererar betydande mängder träflis, sågspån och flisor, som tar upp värdefull plats och medför höga avfallsavgifter.

För att öka resursutnyttjandet, minska avfall och öka ekonomisk avkastning bestämde kunden att omvandla detta avfall till förnybar bränsle genom en biomass briquette extruder.

Vifaa vilivyopendekezwa: extruder wa briquette ya mkaa wa mkaa & kukaanga hewa

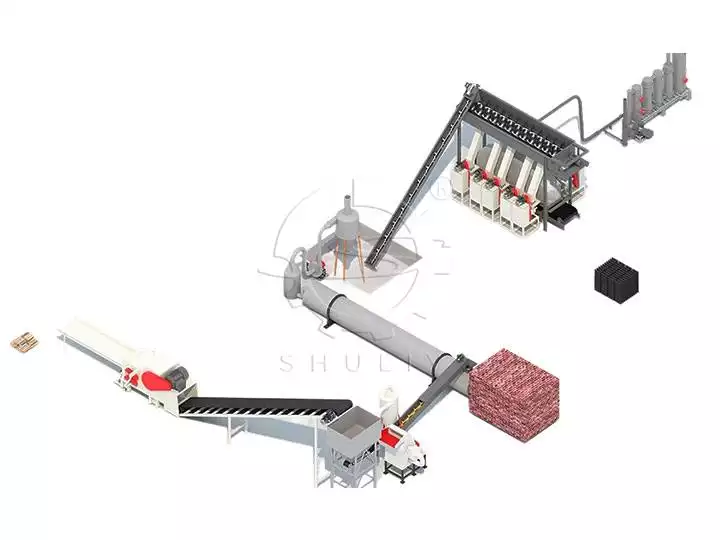

Efter noggrant förståelse av kundens krav rekommenderade Shuliy en kompakt, högpresterande träbriquetteveproduktionslinje som består av följande två kärnenheter:

Lufttorkare

- Modell: SL-220

- Nguvu: 4kW

- Utdata: 200–300kg/h

- Konstruktion: Utrustad med en cyclon

- Funktion: Minska det maximala fuktinnehållet i råa träflisor till under 12% för att säkerställa enhetlig formningskvalitet

Mashine ya Briquetting ya Sawdust

- Mfano: SL-50

- Nguvu: 18.5kw

- Kapacitet: 250 kg per timme

- Typerna: Hexagonal tärning

- Spänning: 380V, 50Hz, tre-fas

- Vikt: 550kg

- Träförpackning storlek: 1580*660*1650mm

- Funktioner: Kompakt konstruktion, enkel drift, lätt underhåll, lämplig för direkt bearbetning av råmaterial som träflis och sågspån

Denna biomassa briquettproduktion line integrerar sömlöst hela processen från råmaterialtorkning till briquettdannelse. Den kan leverera värme för egen användning eller sälja färdiga produkter till den lokala marknaden.

Manufaa ya mradi kwa Bulgaria

Bulgarien upplever långa vintrar med hög efterfrågan på uppvärmningsbränsle. Genom att anta Shuliy träåtervinningsutrustning kan vår kund bearbeta träavfall till rena bränslepelare, samtidigt lösa avfallsproblem och möjliggöra lokal produktion av hållbar energi.

- Energisparande & miljövänlig: Använd avfall som råvara, eliminerar behovet av ytterligare fossila bränslen.

- Högt värde: Premium marknadspris för bränselstavar med omfattande distributionskanaler.

- Låg underhåll: Stabil drift och lätt underhåll.

- Dubbel intäktsström: Värma hem samtidigt som exportvinster genereras.

Uwasilishaji & huduma

Shuliy tillhandahåller omfattande lösningar och eftermarknadsstöd för biomass briquette extruder:

- Mzunguko wa uzalishaji: Imekamilika ndani ya siku 20 za biashara

- Muda wa dhamana: Miaka 12

- Njia ya usafirishaji: Uwasilishaji wa CIF hadi Bandari ya Thessaloniki, Ugiriki

- Msaada wa kiufundi: Maelekezo ya usakinishaji wa mbali na video za uendeshaji

- Masharti ya malipo: amana ya 40%, salio linapaswa kulipwa kabla ya usafirishaji

Kunderna berömmer Shuliy:s professionella snabbhet och noggranna service.

Om du också är intresserad av utrustning för träåtervinning, vänligen kontakta oss när som helst för mer detaljer!