Utangulizi na mchakato wa makaa ya briquette ya sawdust

Jedwali la Yaliyomo

Mkaa wa briquette ya machujo ya mbao hutengenezwa kwa takataka za majani kwa ajili ya kusagwa, kukaushwa, kuweka briquet, kisha kuangaza kwenye mkaa. Mkaa wa briquette wa biomasi una kiasi cha kaboni kwenye mimea, na mimea baada ya kusindika kuwa utaratibu wa mkaa, na ni mali ya matumizi ya mimea iliyotupwa kwenye hazina ya kulinda mazingira ya mradi.

Utangulizi wa makaa ya briquette ya vumbi

- Malighafi: Mavumbi ya mbao, matawi ya miti, maganda ya mpunga, maganda ya mianzi, maganda ya karanga, maganda ya alizeti, mabaki ya manyoya, mabua ya mahindi, mashina ya mahindi, mashina ya pamba, maganda ya nazi, maganda ya kahawa, na kila aina ya vichaka na vijiti.

- Kanuni ya kazi: Joto la juu, kaboni; kwanza kutengeneza briketi za vumbi la mbao, kisha kuweka kaboni kwenye briketi za mkaa

- Evifaa vilivyotumika: Mashine ya extruder ya briquette ya vumbi, tanuru ya mkaa

Tabia za uzalishaji

- Hakuna haja ya kuongeza wambiso wowote na kemikali hatari.

- Unyevu wa malighafi uko ndani ya 8-12%.

- Mfumo wa juu wa kukausha hewa ya moto hupitishwa, na athari ya kukausha ni nzuri sana.

- Vifaa vya kaboni kwa halijoto ya juu, utakaso, uondoaji wa moshi vinaweza kubadilisha bidhaa zilizomalizika nusu kuwa zisizo na moshi, mkaa safi usio na harufu, kwa dhamana ya kitaalamu na hakuna hatari iliyofichika.

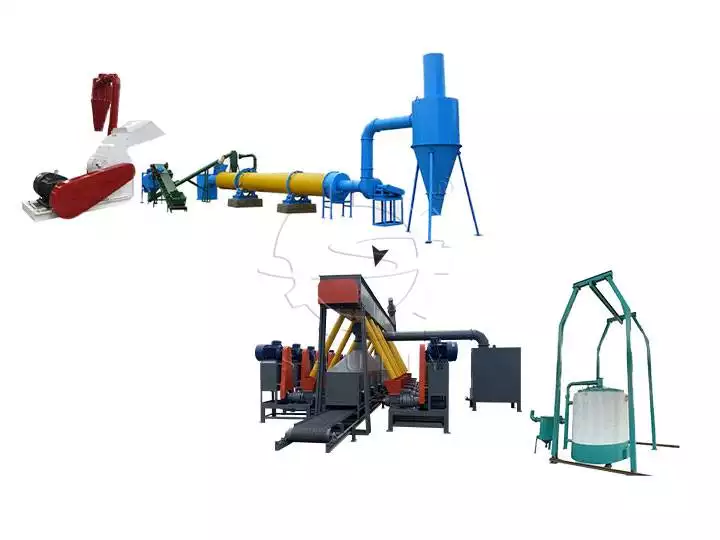

Mchakato wa mtiririko wa kutengeneza makaa ya briketi ya machujo ya mbao

Mchakato wa uzalishaji wa mkaa wa briquette umegawanywa katika: maandalizi ya malighafi, kutengeneza fimbo, uwekaji wa kaboni, pato la sehemu kuu tatu.

Maandalizi ya malighafi

Maandalizi ya malighafi ni mfumo unaojumuisha uchunguzi, kusaga, kukausha na kutoa. Kusanya mkaa wa kutosha, maganda ya mpunga au vingine kwa ajili ya kutengeneza briketi.

Briketi za vumbi la mbao zikitoka nje

Mchakato wa kutengeneza fimbo unajumuisha kutoa, kukata na kukusanya. Na vifaa kuu ni mashine ya briquette ya kuni.

Carbonisation

Mchakato wa ukaaushaji unajumuisha usafirishaji, upakiaji, ukaaushaji na kutoa kwenye jiko. Kwa ujumla, tunatumia jiko la wima la makaa ya mawe kwa ajili ya mchakato huu.

Mchakato wa uzalishaji unaweza pia kutumia vifaa vingine, kama vile: malighafi ni kubwa basi zinaweza kuwekwa kwenye kipasua; unyevu wa malighafi ni mkubwa sana basi zinaweza kuwekwa kwenye kifaa cha kukausha. Mstari wa uzalishaji wa makaa ya mawe ya mkaa ndio chaguo bora ikiwa uzalishaji unafanywa haraka.