Roterende trommeldroogmachine voor zaagsel, rijstschillen

Zaagseldroogmachine | Rijstschil Droger Machine

Roterende trommeldroogmachine voor zaagsel, rijstschillen

Zaagseldroogmachine | Rijstschil Droger Machine

Kenmerken in één oogopslag

Inhoudsopgave

De roterende trommeldroger machine, of trommeldroger, is droogapparatuur om diverse materialen zoals zaagsel en rijstkaf te drogen, waarbij het watergehalte wordt geregeld tussen 10% en 12%.

Als u dit soort zaagseldroogmachine wilt gebruiken, moet de grootte van het toevoermateriaal ≤5 mm zijn.

Het werkt altijd in de houtskoolproductielijn om kolenbriketten van hoge kwaliteit te produceren.

Kenmerken van roterende trommeldrogermachine

- Efficiënt drogen: Roterende droogmachine kan de materialen snel efficiënt drogen en de productie-efficiëntie verbeteren.

- Breed toepasbaar: Het is geschikt voor alle soorten materialen, inclusief kleine korrels, klontjes, poeder en andere verschillende soorten materialen.

- Betrouwbaar en stabiel: De apparatuur heeft een stabiele structuur, betrouwbare werking, vermindert uitvaltijd en verbetert de productie-efficiëntie.

- Gelijkmatige droging: Materialen in de roterende trommel rollen gelijkmatig zodat ze tijdens het droogproces gelijkmatig worden verwarmd.

- Flexibele indeling: Flexibele indeling en installatie kunnen worden uitgevoerd afhankelijk van de omstandigheden ter plaatse, waardoor ruimte wordt bespaard.

- Ondersteuning na verkoop: Wij bieden een perfecte after-sales service, inclusief reparatie, onderhoud, enz., om de stabiele werking van de apparatuur op lange termijn te garanderen.

Technische gegevens van een roterende trommeldroger te koop

Model: SL-800, SL-1000, SL-1200, SL-1500

Capaciteit: 500kg/u, 1000kg/u, 2000kg/u, 3000kg/u

Vermogen: 2.2+7.5kw, 3+15kw, 3+18.5kw, 5.5+22kw

Invoer diameter: ≤5mm

Toepasselijke materialen: zaagsel, rijstkaf, zand, kolen en andere kleine fijne materialen

Welke materialen kunnen worden gedroogd door een roterende trommeldroger?

Trommeldroger is geschikt voor het drogen van veel soorten materialen, zoals zaagsel, rijstkaf, kolenpoeder, erts, gips, houtsnippers, wijnmoes, granen, fruitpulp, zand, organische chemicaliën enzovoort.

Of het nu gaat om nat erts of natte houtsnippers, de roterende droogmachine kan de droogtaak efficiënt voltooien en de materialen drogen tot de gespecificeerde vochtigheid.

Toepassingen voor roterende droogmachine

Het wordt voornamelijk gebruikt om natte materialen te drogen, om de vochtigheid van de materialen te verminderen en de productie-efficiëntie te verbeteren.

Deze apparatuur wordt veel gebruikt in diverse industriële velden, zoals mijnbouw, metallurgie, bouw, chemische industrie, enz., en kan een verscheidenheid aan materialen drogen.

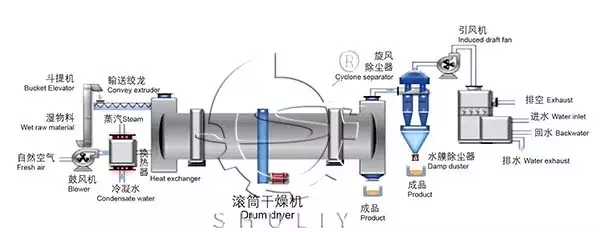

Werkproces van de roterende trommeldroger

Het werkingsprincipe van de trommeldroger is relatief eenvoudig en efficiënt.

Stap 1: Materiaaltoevoer

Het materiaal komt de trommel binnen via het toevoerapparaat, meestal met behulp van een schroeftransporteur.

Stap 2: Warmte-uitwisseling

Het materiaal wisselt warmte uit met de brandstof in de roterende cilinder, waardoor hete lucht met hoge temperatuur ontstaat.

Stap 3: Materiaal rollen

Materiaal rolt en draait in de roterende cilinder en wordt geleidelijk gedroogd door zwaartekracht en hete lucht.

Stap 4: Vochtafvoer

Tijdens het droogproces wordt het vocht via de uitlaatpoort afgevoerd, waardoor een snelle droging van het materiaal wordt gerealiseerd.

Ontwerp van een roterende trommeldrogermachine

Zoals hierboven weergegeven, heeft de zaagseldroogmachine componenten als inlaat, trommeldroger, uitlaat, stofafscheider, enz.

Door de unieke eigenschappen van de droogmolen heeft de machine verschillende lengtes. Indien u geïnteresseerd bent, neem dan gerust contact met ons op voor meer informatie!

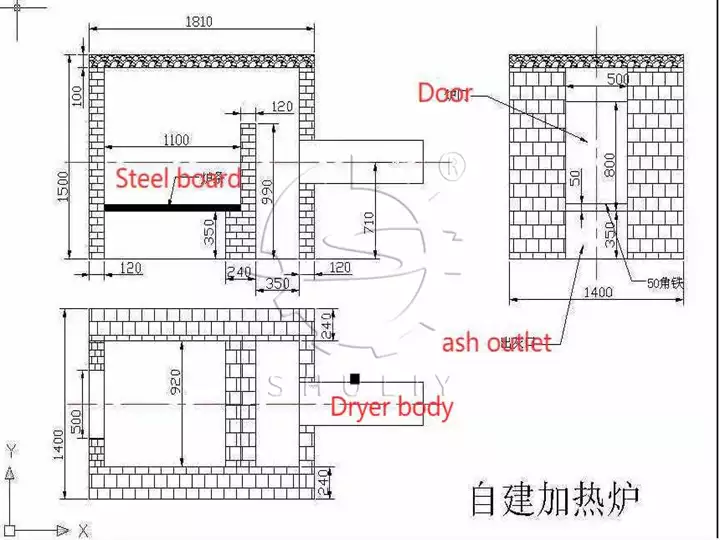

Drogende brandstof voor rijstschildroogmachine

De apparatuur gebruikt meestal brandstof als energiebron, en veelgebruikte brandstoffen zijn steenkool, aardgas, diesel, enz.

Je kunt ook je eigen steenoven bouwen en hout stoken, wat zuiniger is.

De brandstof wordt verbrand in de roterende trommeldroogmachine om warmte-energie op hoge temperatuur te produceren, die met behulp van hete lucht naar het materiaal wordt geleid om het drogen van het materiaal te realiseren.

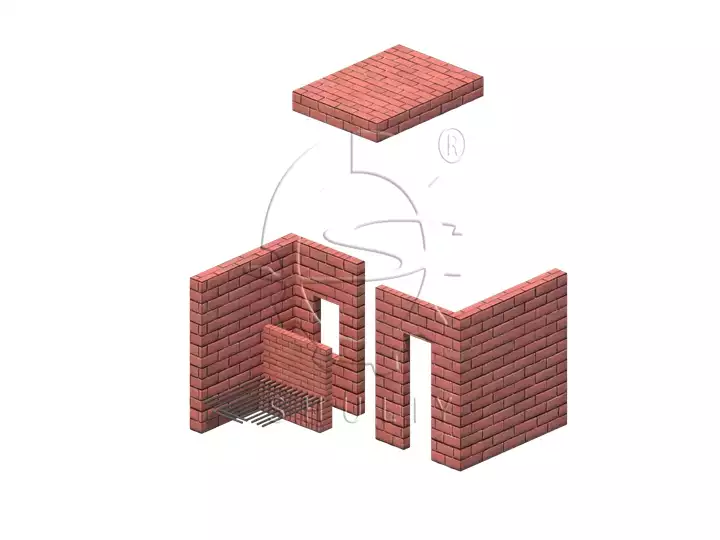

Steenovenontwerp om warmtebronnen aan te bieden

Waarom de roterende droogmachine gebruiken in de houtskoolproductielijn?

De roterende droogmachine speelt een belangrijke rol in verschillende productielijnen. In houtskoolproductielijnen wordt het vaak gebruikt voor de voorkant van de lijn.

Of de houtskool nu wordt verkoolt met een houtskooloven of direct tot zaagselbriketten wordt verwerkt, de grondstofvereiste is 10%-12% vocht.

Daarom kan deze droger u effectief helpen bij het op grote schaal verwerken van grondstoffen

Pakket en levering van zaagseldroogmachine met roterende trommel

Als u hoogwaardige zaagselbriketten of houtskool wilt maken, is deze machine de ideale keuze voor u. Neem contact met ons op voor meer machinegegevens!

Industriële hamermolen voor het versnipperen van hout

Houtmolen is een krachtige en veelzijdige machine voor…

Industriële houtversnipperaar voor het maken van houtstof

Houtvermaler, ook bekend als zaagselmachine of…

Waarom een zaagsel drumdroger nodig in de productie van houtskool en biomassa-briketten?

In het productieproces van houtskool- en biomassa-staven, de…

Heet product

Geperste houten palletmachine

Geperste houten palletmachine is voor het vervaardigen van geperste…

Houtskoolmachine voor de productie van kokosnootschalenhoutskool

De machine voor het maken van kokosnootschilhoutskool is ontworpen om…

Roterende trommeldroger voor zaagsel, rijstschillen

De roterende droogtrommel is bedoeld om diverse…

Hydraulische shisha-houtskoolpersmachine

Deze shisha-houtskoolpersmachine is bedoeld om efficiënt te…

Industriële houtversnipperaar voor het maken van houtstof

Houtvergruizer is gespecialiseerd in het versnipperen van hout…

Hamermolen voor het malen van houtskool en kolen

Houtskoolmaler kan verschillende soorten… vergruizen

Batch-type droger voor briketten, honingraatkolen, waterpijp-houtskool

Deze houtskooldroogmachine wordt gebruikt om te drogen…

Horizontale koolstofiseringsoven voor houtskoolproductie

Horizontale carbonisatieoven wordt gebruikt om hout…

Ronde & kubieke shisha-houtskooltabletpersmachine

Deze shisha-houtskoolmachine is bedoeld voor het efficiënt…