De VAE bestelde een houtskoolmachine voor zaagselbriketten om winst te maken in de houtskoolhandel

Inhoudsopgave

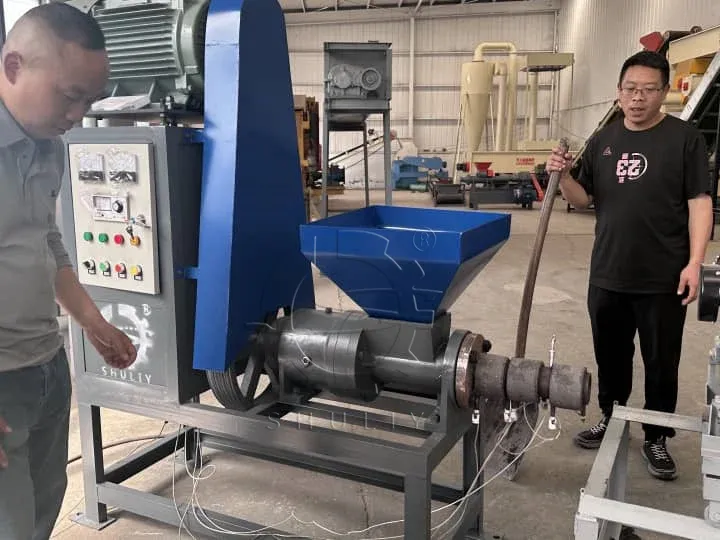

De klant uit de VAE heeft onlangs onze zaagselbriket houtskoolmachine (pini kay briketmachine en verticale carbonisatieoven) gekocht voor houtskoolproductie.

Met de combinatie van deze twee machines kan de klant afvalstoffen efficiënt omzetten in hoogwaardige biomassabrikettenhoutskool. Dit artikel zal deze samenwerkingscasus in detail introduceren en de voordelen van onze apparatuur in de daadwerkelijke productie laten zien.

Achtergrond van de klant

De klant is een nieuw opgerichte biomassahoutskoolproducent uit de Verenigde Arabische Emiraten. De klant wil de overvloedige lokale biomassa-afvalbronnen, zoals zaagsel, rijstschillen, enz., gebruiken om hoogwaardige zaagselbrikettenhoutskool te produceren om aan de marktvraag te voldoen.

Onze oplossing

Om aan de productiebehoeften van de klant te voldoen, bieden wij de klant een complete set machines voor het maken van zaagselbrikettenhoutskool.

- Eerst wordt het biomassaafval met behulp van onze machines tot compacte staven geperst Machine voor het maken van zaagselbriketten. Deze stap verhoogt niet alleen de dichtheid van de grondstof, maar legt ook de basis voor het daaropvolgende carbonisatieproces.

- Vervolgens plaatst de klant deze briketten in de verticale verkolingsoven voor carbonisatie. De verticale verkolingsoven kan een stabiele omgeving op hoge temperatuur bieden om ervoor te zorgen dat de biomassabriketten in korte tijd volledig worden verkoold.

Voordelen van onze houtskoolmachine voor zaagselbriketten

- Efficiënte productie: De maker van biomassabriketten kan het biomassa-afval snel tot staven comprimeren, wat de productie-efficiëntie aanzienlijk verbetert.

- Energiebesparing en milieubescherming: De verticale carbonisatieoven heeft een geavanceerd ontwerp, een laag energieverbruik en goede milieubeschermingsprestaties, waardoor de koolstofuitstoot in het productieproces wordt verminderd.

- Kwaliteitsborging: Onze apparatuur is gemaakt van hoogwaardige materialen met een lange levensduur en betrouwbare prestaties.

Verschillende punten die klanten ertoe aanzetten de bestelling te plaatsen

- Capaciteit en motorgrootte van de machine: De klant heeft hoge capaciteitseisen, we hebben de parameters van de machine gedetailleerd uitgelegd en de meest geschikte motorconfiguratie aanbevolen.

- Machinegebruik en installatie: Onze klant maakt zich zorgen over de complexiteit van de installatie en bediening. We hebben gedetailleerde installatie-instructies en bedieningshandleidingen verstrekt en technici gestuurd om begeleiding ter plaatse te bieden.

- Kwaliteit van apparatuur en service na verkoop: Klanten hechten belang aan de kwaliteit van de machine voor het maken van zaagselbriketten en de after-sales service. Wij beloven hoogwaardige after-sales ondersteuning te bieden, inclusief levering van onderdelen en technische ondersteuning.

Klantrecensies

Klanten zijn zeer tevreden over onze apparatuur en service. Ze waardeerden vooral onze professionele begeleiding bij de selectie en installatie en inbedrijfstelling van apparatuur, evenals onze uitgebreide ondersteuning voor hun productiebehoeften.

Momenteel produceert de klant met succes zaagselbrikettenhoutskool en kijkt uit naar een verdere samenwerking met ons in de toekomst.

Neem contact met ons op voor meer machinedetails!

Als u geïnteresseerd bent in onze zaagselbriket houtskoolmachine of vragen heeft, neem dan gerust contact met ons op. Wij bieden u de beste kwaliteit producten en diensten om u te helpen slagen in uw biomassaproductiebedrijf voor houtskool.