लकड़ी के फूस ब्लॉकों के लिए चूरा ब्लॉक बनाने की मशीन

चूरा लकड़ी ब्लॉक हॉट प्रेस मशीन | पैलेट ब्लॉक मशीन

लकड़ी के फूस ब्लॉकों के लिए चूरा ब्लॉक बनाने की मशीन

चूरा लकड़ी ब्लॉक हॉट प्रेस मशीन | पैलेट ब्लॉक मशीन

विशेषताएं एक नज़र में

विषयसूची

लकड़ी के पैलेट ब्लॉक बनाने वाली मशीन एक विशेष मशीन है जो लकड़ी की चिप्स, लकड़ी के बुरादे, लकड़ी के शेविंग आदि को 75*75 मिमी, 80*80 मिमी, 90*90 मिमी, 90*120 मिमी, 100*100 मिमी आदि आकार के मजबूत लकड़ी के पैलेट ब्लॉक में संपीड़ित करती है।

यह चूरा ब्लॉक बनाने की मशीन संपीड़न, मोल्ड बनाने और ब्लॉक काटने की प्रक्रियाओं को स्वचालित करती है।

इसका उच्च दबाव और उन्नत तकनीक यह सुनिश्चित करती है कि उत्पादित लकड़ी के फूस के ब्लॉक में उत्कृष्ट भार-वहन क्षमता और स्थिरता हो, और इसका व्यापक रूप से रसद, भंडारण और परिवहन में उपयोग किया जा सके।

हमारी चूरा लकड़ी ब्लॉक हॉट प्रेस मशीन पर्यावरण के अनुकूल होने के साथ-साथ लकड़ी के संसाधनों का कुशलतापूर्वक उपयोग कर सकती है और लागत कम कर सकती है।

यह सभी प्रकार के लकड़ी के कचरे के लिए उपयुक्त है और उद्यमों के लिए हरित और टिकाऊ फूस समाधान प्रदान करता है।

लकड़ी का बुरादा फूस ब्लॉक बनाने की मशीनों के प्रकार

हॉपर के आकार से पैलेट ब्लॉक मशीन को दो प्रकारों में विभाजित किया जा सकता है: आकार का हॉपर और गोल हॉपर।

दोनों प्रभावी ढंग से कच्चे माल के परिवहन की दक्षता में सुधार करते हैं और यह सुनिश्चित करते हैं कि उच्च गुणवत्ता वाले लकड़ी के चिप पैलेट ब्लॉक का उत्पादन करने के लिए सामग्री को समान रूप से और लगातार लकड़ी के फूस ब्लॉक मशीन में डाला जाता है।

उत्पादन क्षमता और गुणवत्ता में सुधार के लिए उत्पादन स्थल और उत्पादन आवश्यकताओं के अनुसार सही प्रकार का हॉपर चुनना महत्वपूर्ण है।

संपीड़ित लकड़ी फूस ब्लॉक बनाने की मशीन के लाभ

- कुशल उत्पादन: दबाई गई लकड़ी की फूस की ब्लॉक मशीन 2m3/24h का उत्पादन कर सकती है, जिससे उत्पादन क्षमता में काफी सुधार होता है और उत्पादन की जरूरतों को पूरा किया जा सकता है।

- बहुकार्यात्मकता: लकड़ी के फूस के ब्लॉक के लिए कच्चा माल चावल की भूसी, चूरा, लकड़ी के चिप्स, लकड़ी की छीलन आदि हो सकता है।

- किफायती और व्यावहारिक: उपकरण के कुशल उत्पादन और कम रखरखाव लागत के कारण, संपीड़ित लकड़ी के फूस ब्लॉक बनाने की मशीन में उच्च अर्थव्यवस्था और दीर्घकालिक उपयोग में निवेश पर उच्च रिटर्न है।

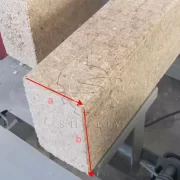

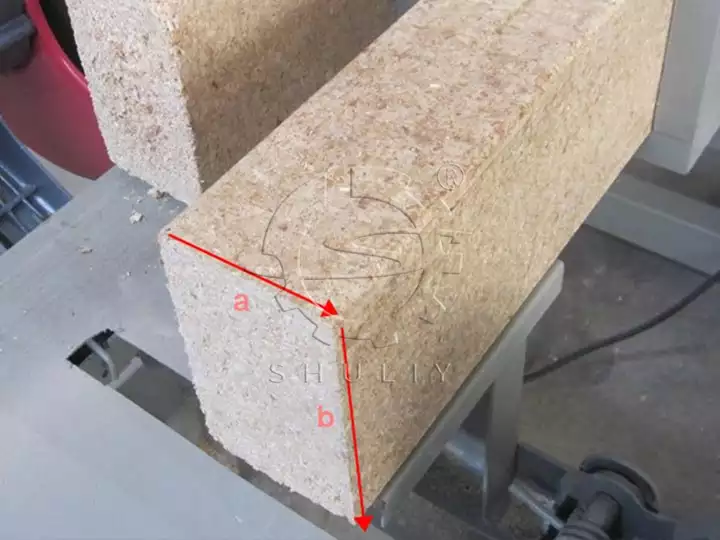

लकड़ी के फूस ब्लॉक बनाने की मशीन के तैयार उत्पाद

लकड़ी के फूस के ब्लॉक बनाने की मशीन के तैयार उत्पाद उच्च गुणवत्ता वाले और मजबूत लकड़ी के फूस के ब्लॉक हैं। ये ब्लॉक आमतौर पर आकार में चौकोर या आयताकार होते हैं, जिनमें छेद होते हैं या बिना छेद होते हैं।

आकार 75*75मिमी, 80*80मिमी, 90*90मिमी, 90*120मिमी, 100*100मिमी, 100*115मिमी, 100*140मिमी, और 140*140मिमी हैं।

इसके अलावा, आकार भी अनुकूलन योग्य हो सकता है। इसलिए, यदि आप रुचि रखते हैं, तो हमसे संपर्क करें और हम आपको एक विशेष समाधान प्रदान करेंगे।

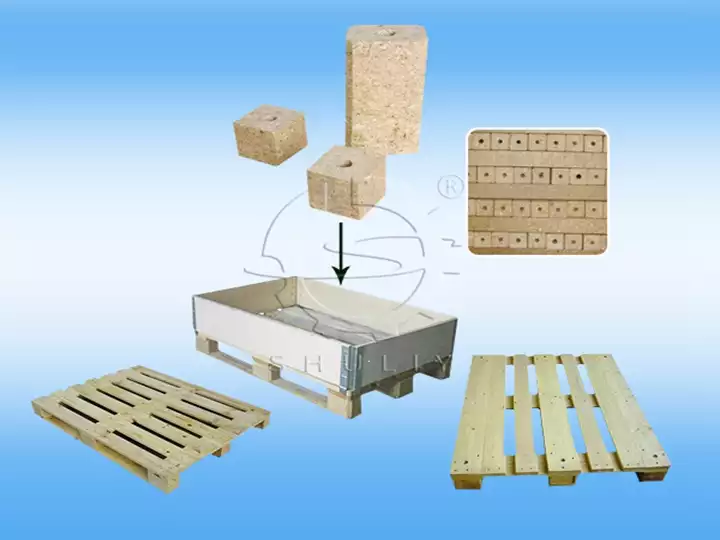

बिक्री के लिए लकड़ी के फूस ब्लॉक के कार्य

लकड़ी के फूस के ब्लॉक लकड़ी के फूस के निर्माण का एक महत्वपूर्ण हिस्सा हैं।

उनके मुख्य कार्य में फूस को संरचनात्मक समर्थन और स्थिरता प्रदान करना शामिल है, यह सुनिश्चित करना कि यह भारी भार को सुरक्षित रूप से ले जा सके और परिवहन कर सके।

इन ब्लॉकों को रणनीतिक रूप से फूस के कोनों और केंद्रों पर रखा जाता है, जिससे फोर्कलिफ्ट और फूस ट्रकों को फूस को आसानी से उठाने और स्थानांतरित करने की अनुमति मिलती है।

इसके अतिरिक्त, लकड़ी के फूस के ब्लॉक फूस को जमीन से ऊपर उठाते हैं, सतहों के साथ सीधे संपर्क को रोकते हैं और सुचारू संचालन की सुविधा प्रदान करते हैं।

टिकाऊ और पर्यावरण के अनुकूल, ये ब्लॉक उद्योगों में कुशल रसद और आपूर्ति श्रृंखला संचालन को साकार करने में महत्वपूर्ण भूमिका निभाते हैं।

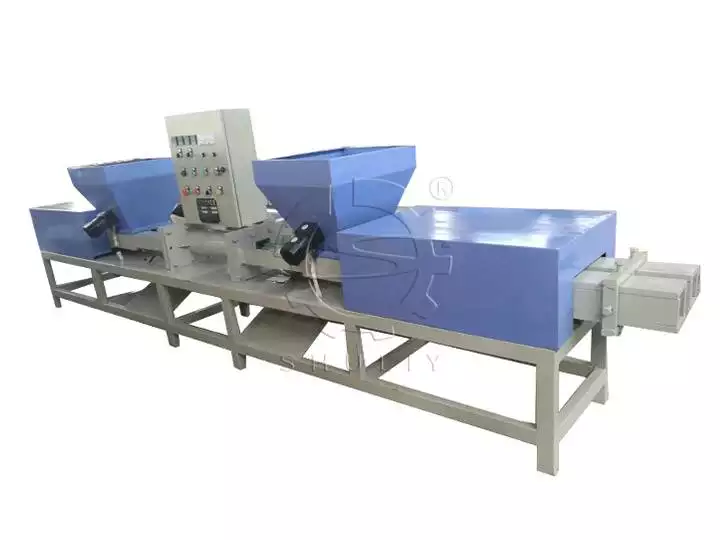

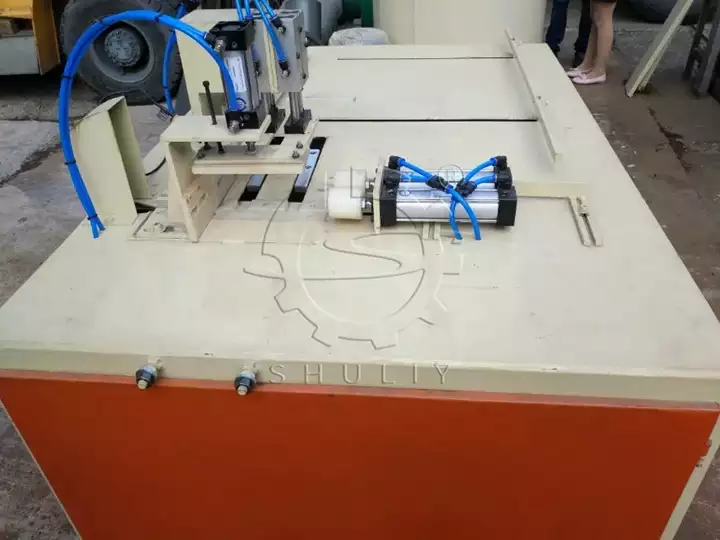

लकड़ी के फूस ब्लॉक बनाने की मशीन की संरचना

जैसा कि ऊपर दिखाया गया है, चूरा लकड़ी ब्लॉक हॉट प्रेस मशीन मुख्य रूप से मिक्सिंग ड्रम, प्रेशर गेज, कंट्रोल कैबिनेट, आउटलेट, कटर इत्यादि से बनी होती है।

लकड़ी के फूस के ब्लॉक कैसे बनाएं?

लकड़ी के फूस के ब्लॉक बनाने के लिए, लकड़ी के चिप्स या चूरा को गोंद या राल जैसे चिपकने वाले पदार्थ के साथ मिलाया जाता है। फिर मिश्रण को वांछित आकार और आकार देने के लिए लकड़ी के फूस के ब्लॉक बनाने वाली मशीन में उच्च दबाव में संपीड़ित किया जाता है।

संपीड़न के बाद, ब्लॉकों को उनकी मजबूती और स्थिरता सुनिश्चित करने के लिए आगे ठीक किया जाता है या सुखाया जाता है। एक बार पूरी तरह से ठीक हो जाने पर, ब्लॉक लकड़ी के फूस बनाने के लिए उपयोग करने के लिए तैयार हैं, जो सामग्री प्रबंधन और परिवहन के लिए एक स्थायी और कुशल समाधान प्रदान करते हैं।

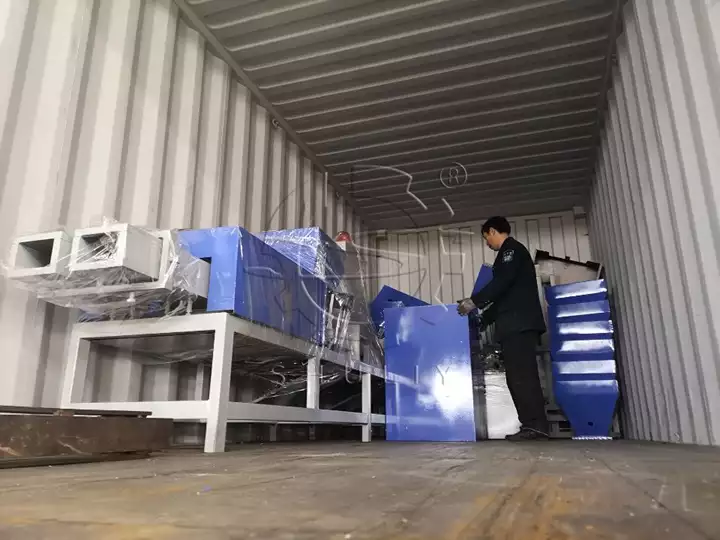

संपीड़ित लकड़ी फूस ब्लॉक बनाने की मशीन का पैकेज और वितरण

परिवहन के दौरान इसकी सुरक्षा सुनिश्चित करने के लिए संपीड़ित लकड़ी फूस ब्लॉक निर्माता को सावधानीपूर्वक पैक किया जाता है। इसे आमतौर पर कुशनिंग और सुरक्षा प्रदान करने के लिए मजबूत लकड़ी के बक्सों या अनुकूलित पैकिंग सामग्री में पैक किया जाता है।

इसके अलावा, परिवहन के दौरान किसी भी क्षति या स्थानांतरण को रोकने के लिए महत्वपूर्ण घटकों को सुरक्षित रूप से बांधा जाता है।

फिर मशीन को गंतव्य के आधार पर परिवहन के एक विश्वसनीय माध्यम (समुद्र, वायु या सड़क) के माध्यम से वितरित किया जाता है।

ग्राहक के स्थान पर समय पर और सुरक्षित डिलीवरी सुनिश्चित करने के लिए उचित हैंडलिंग और ट्रैकिंग तंत्र लागू किए जाते हैं।

दबाए गए लकड़ी के फूस ब्लॉक बनाने की मशीन की तकनीकी विशिष्टताएँ

| नमूना | एसएल-1 | एसएल-2 | एसएल-3 |

| शक्ति | 13 किलोवाट | 15 किलोवाट | 15 किलोवाट |

| क्षमता | 2मी3/24 घंटे | 2मी3/24 घंटे | 2मी3/24 घंटे |

| घनत्व | 550-600 किग्रा/मी3 | 550-600 किग्रा/मी3 | 550-600 किग्रा/मी3 |

| मशीन वजन | 1000 किग्रा | 1080 किग्रा | 1350 किग्रा |

| मशीन का आकार | 5000*600*1420मिमी | 5000*600*1420मिमी | 5000*600*1420मिमी |

हमारी लकड़ी की पैलेट ब्लॉक बनाने वाली मशीन आपको कचरे की लकड़ी से लाभ कमाने में मदद कर सकती है, और हमारे पास बिक्री के लिए दबाए गए लकड़ी के पैलेट मशीन, लकड़ी क्रशर, लकड़ी शेविंग मशीन भी हैं।

यदि आप रुचि रखते हैं, तो अधिक मशीन विवरण के लिए हमसे संपर्क करने का स्वागत है!

स्वचालित लकड़ी पैलेट ब्लॉक उत्पादन लाइन

Shuliy वुड पैलेट ब्लॉक उत्पादन लाइन को… में बदले जाने के लिए उपयोग किया जाता है

सावडस्ट ब्लॉक बनाने वाली मशीन इंडोनेशियाई ग्राहक को लाभ पहुंचाती है

हमने एक इंडोनेशियाई ग्राहक के साथ एक सफलतापूर्वक सहयोग किया है पर एक…

गर्म उत्पाद

लकड़ी काटने के लिए वुड सॉमिल मशीन

लकड़ी की सॉमिल मशीन लकड़ी के तनों को संसाधित करने के लिए डिज़ाइन की गई है…

मात्रात्मक बीबीक्यू कोयला पैकिंग मशीन

BBQ चारकोल पैकेजिंग मशीन का उपयोग … पैकेज करने के लिए किया जाता है…

सावडस्ट, चावल भूसी के लिए रोटरी ड्रम ड्रायर मशीन

रोटरी ड्रायर मशीन विभिन्न… को सुखाने के लिए है

छोटा डिस्क लकड़ी चिप्पर बड़े पैमाने पर लकड़ी चिप बनाने के लिए

डिस्क वुड चिपर को लकड़ी को चिप करने के लिए डिज़ाइन किया गया है,…

लकड़ी के पैलेट ब्लॉक्स के लिए सॉडस्ट ब्लॉक बनाने वाली मशीन

लकड़ी पैलेट ब्लॉक बनाने वाली मशीन…

कोयला संयंत्र के लिए चारकोल ब्रिकेट बनाने वाली मशीन

कोयला ब्रिकेट बनाने वाली मशीन का उपयोग … बनाने के लिए किया जाता है

औद्योगिक पैलेट क्रशिंग मशीन बिक्री के लिए

अपशिष्ट लकड़ी क्रशर मशीन प्रसंस्करण के लिए डिज़ाइन की गई है…

कोयला दबाने के लिए हनीकॉम्ब ब्रिक्वेट मशीन

हमारी हनीकॉम्ब ब्रिक्वेट मशीन विशेषीकृत उपकरण है…

गोल और घन शिशा कोयला टैबलेट प्रेस मशीन

यह शीशा चारकोल मशीन कुशल… के लिए है