Come produrre briquettes di legno?

Sommario

I briquettes di segatura di legno stanno diventando sempre più popolari nel mercato globale come combustibile ecologico, pulito e ad alto valore calorifico. Molti clienti ci chiedono come produrre briquettes di legno.

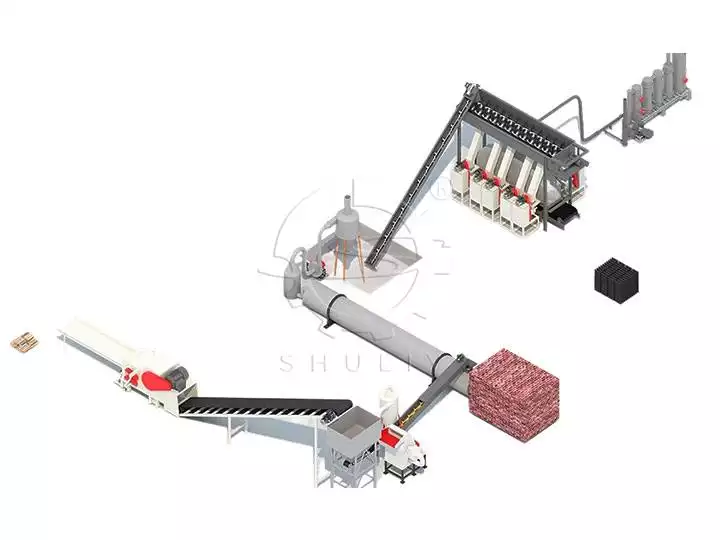

In questo articolo, combineremo le attrezzature per la produzione di bricchette di segatura di Shuliy con le esigenze reali dei clienti per introdurre il processo di produzione e la scelta delle attrezzature in dettaglio, il che ti aiuterà a entrare in produzione rapidamente e a realizzare il profitto.

Requisiti delle materie prime per i briquettes di legno

Per produrre briquettes di segatura di alta qualità, dobbiamo prima partire dalle materie prime. Le materie prime comuni per le briquettes di segatura di legno includono:

- Trucioli di legno, segatura, segatura

- Bagassa, trucioli di bambù, paglia di riso, gusci di arachidi

- Corteccia, gusci di palma e altri rifiuti di biomassa

Il controllo del contenuto di umidità al 8%-12% è il migliore, troppo umido non è facile da modellare, troppo secco influisce sulla forza di legame.

Attrezzatura chiave: macchina per la produzione di briquettes di legno Shuliy

L'attrezzatura principale è chiamata pressa per bricchette di segatura. Il suo principio di funzionamento è quello di pressare le schegge di legno in polvere fine in aste combustibili di forma regolare mediante alta temperatura e alta pressione. I principali vantaggi includono:

- Vari stampi disponibili

- Buona modellatura con alta pressione

- Operazione semplice e bassa manutenzione

- Linea di produzione a macchina singola o combinazione di più macchine in base alla produzione richiesta

Fasi di produzione dei briquettes di segatura

Il processo completo di produzione delle briquettes di legno è il seguente:

- Frantumazione delle materie prime: utilizzare un frantoio per legno per trasformare le materie prime in particelle fini.

- Processo di essiccazione: l'umidità è controllata nell'intervallo desiderato (8%-12%).

- Pressatura: le briquettes vengono pressate nella forma desiderata utilizzando una macchina per briquettes di segatura Shuliy.

- (Opzionale) Carbonizzazione: Se carbone di legna di bricchette di segatura deve essere prodotto, può essere ulteriormente lavorato in un forno di carbonizzazione.

Vuoi fare briquettes di legno? Contattaci ora per un preventivo!

Che tu sia un progetto start-up o in fase di espansione e aggiornamento, Shuliy può offrirti soluzioni professionali complete. Lascia le tue informazioni e ti invieremo un preventivo per l'attrezzatura e un piano di produzione entro 24 ore!