Succesvolle installatie SL-1200 carbonisatieoven in Groot-Brittannië

Inhoudsopgave

Goed nieuws uit het VK! Onze klant heeft een SL-1200 carbonisatiefen besteld om afvalhout om te zetten in waardekool om winst te maken. Deze klant heeft een in het VK gevestigde houtverwerkingsfabriek die houten meubelen produceert. Aangezien het productieproces een grote hoeveelheid houtsnippers en houtresten genereert, wil de klant dit afvalmateriaal kunnen gebruiken om houtskool te produceren met behulp van een houtskooloven.

De zorgen van de Britse klant over de carbonisatieoven

De klant maakt zich bij de aanschaf van de continue houtskooloven vooral zorgen over de volgende twee zaken:

- Probleem met warmtebron: Er is geen gasleiding in zijn fabriek, dus hij moet rekening houden met het probleem van de warmtebron.

- Installatieprobleem: Het was de eerste keer dat hij de continue carbonisatieoven kocht, dus hij wist niet veel over het installatieproces.

Oplossing voor zijn zorgen

- Als reactie op zijn probleem met de warmtebron hebben we een continue verkolingsoven die afvalhout of een brander gebruikt als brandstof voor verwarming. Het is erg handig en eenvoudig, en het gas dat wordt geproduceerd tijdens de productie van houtskool kan worden gerecycled om warmte te genereren.

- Bij installatieproblemen kunnen wij gedetailleerde installatie-instructies verstrekken en ervoor zorgen dat onze technicus de installatie ter plaatse begeleidt.

We hebben het vertrouwen van deze klant gewonnen door zijn warmtebron- en installatieproblemen op te lossen en hebben uiteindelijk het contract met succes ondertekend.

Unieke kenmerken van de Shuliy carbonisatieoven

- Het aannemen van afvalhout om te verwarmen, heel gemakkelijk en handig.

- Samen met de installatiehandleiding en zelfs de technicus sturen om te helpen bij de installatie ter plaatse.

- Hoge mate van automatisering, eenvoudige bediening, besparing op mankracht.

- Hoge output, hoge efficiëntie, tijd besparen.

- Milieubescherming en energiebesparing, geen vervuiling.

Machinelijst voor Groot-Brittannië

| Item | Specificaties | Aantal |

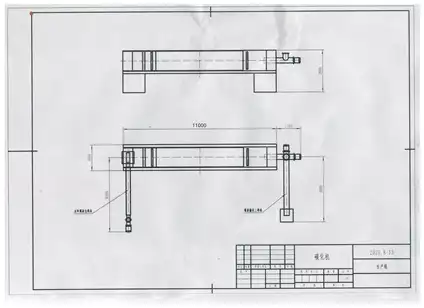

Continue carbonisatieoven | Model: SL-1200 Diameter: 11,5*2*1,9m Gewicht: 13t Capaciteit: 1000 kg per uur Vermogen: 25 kW Invoergrootte: minder dan 10 cm Carbonisatieverhouding voor hout:3-4:1(3-4 t hout:1t houtskool) Carbonisatietemperatuur: 600-800° De machine bevat 6 motoren, 2 voedende, 1 lossende, een hoofdmotor en een ventilator | 1 set |

Opmerkingen over deze carbonisatiefen:

- Brandstof: 15-20 kg LPG per dag (eerst 1-1,5 uur branden met LPG, daarna geen LPG-verbranding meer nodig). Het gas dat tijdens de carbonisatie wordt geproduceerd, is recyclebaar.

- Ruimte: Lengte: 22 meter; Breedte: minder dan 10 meter; Hoogte: ruim 5 meter.

- Werknemer: twee werknemers. De een is verantwoordelijk voor het voeden, de ander voor het lozen.