Honingraatbrikettenmachine voor het persen van kolen

Honingraatkolenbriketmachine | Machine voor het briketteren van kolen

Honingraatbrikettenmachine voor het persen van kolen

Honingraatkolenbriketmachine | Machine voor het briketteren van kolen

Kenmerken in één oogopslag

Inhoudsopgave

Onze honingraat brikettenmachine is gespecialiseerd in het produceren van honingraat kolen door houtskoolpoeder of kolenpoeder (dia. <1mm) te persen.

Deze machine kan honingraat- en zeshoekige kolen maken. Het loopt 45 stuks per minuut. Voor honingraatkolen is dit één briket per keer. Voor zeshoekige steenkool is het 3-4 stuks briket per keer.

Het kan de elektromotor of de dieselmotor als machinevermogen gebruiken. Bovendien heeft het een grote capaciteit, zijn er veel mallen te vervangen en heeft het een lange levensduur. Zo is de machine populair in Oeganda, Rusland, Sri Lanka, Kazachstan, enz.

Heeft u interesse in deze kolenbrikettenmachine? Zo ja, neem dan nu contact met ons op! Wij ontwerpen de meest geschikte oplossing voor uw houtskoolbedrijf.

Kenmerken van honingraatkolenbriketmachine

- Onze honingraatbrikettenmachine is zeer efficiënt, met een capaciteit van het runnen van 45 stuks per minuut.

- Het kan maken honingraat steenkool En zeshoekige houtskoolbriket.

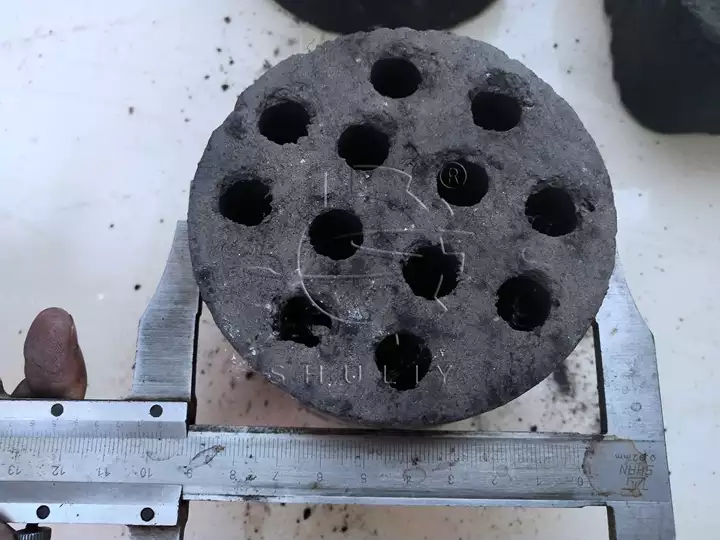

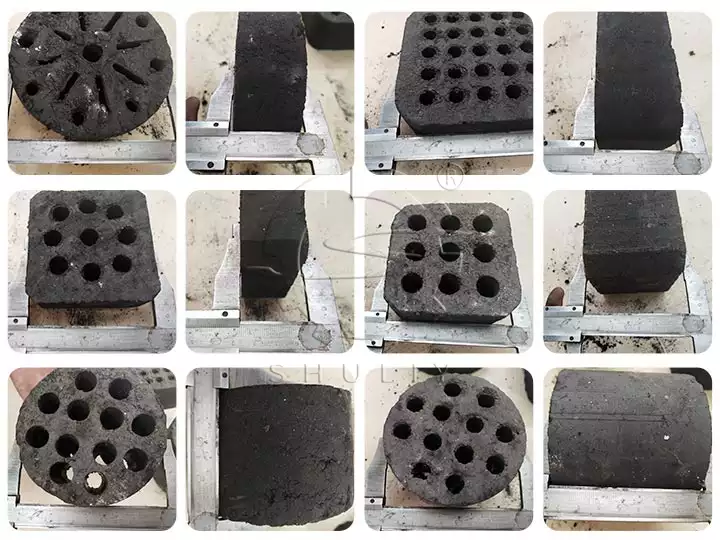

- Honingraatkolenbriket: dia. van 12,14 cm, hoogte van 7-22 cm.

- Zeshoekige houtskoolbriket: lengte van 7 cm, hoogte van 7-22 cm, diagonale dia. van 5 cm.

- De kolenbriketmachine heeft voorpersen, die eindproducten met een hoge dichtheid kan produceren.

- Deze machine heeft geen accessoires, is niet gemakkelijk te beschadigen en heeft een lange levensduur.

- Wij kunnen Pas de kleur van de machine, de vorm en grootte van het eindproduct, de spanning en het vermogen van de machine aanenz.

Technische parameters van de machine voor het maken van kolenbriketten

| Model | SL-120 | SL-140 | SL-160 | SL-220 |

| Capaciteit | 45 stks/min | 45 stks/min | 45 stks/min | 45 stks/min |

| Kolendiameter | φ100-φ120mm | φ100-φ140 | φ100-φ160 | φ180-φ220 |

| Kolenhoogte | 70-80 mm | 70-80 mm | 70-80 mm | 100 mm |

| Stroom | 7,5 kW | 7,5 kW | 7,5 kW | 11 kW |

| Assnelheid | 406 tpm | 406 tpm | 410 tpm | 460 tpm |

| Dimensie | 1280*1160*1750mm | 1320*1260*1850mm | 1400*1300*2000mm | 1580*1450*2200mm |

| Weerstand tegen steenkooldruk | 60-90kg | 60-90kg | 60-90kg | 60-90kg |

| Gewicht | 1200 kg | 1400 kg | 2000 kg | 4000 kg |

In de bovenstaande tabel hebben we het machinemodel, het vermogen, het vermogen, het gewicht, de grootte enzovoort beschreven. Het kan als referentie worden gebruikt bij de keuze van de machine.

Als u meer details wilt, neem dan nu contact met ons op!

Mallen voor honingraatbrikettenmachine

Bij het gebruik van een honingraatkolenmachine voor de productie van steenkool zijn mallen noodzakelijk. Verschillende schimmels kunnen verschillende houtskool produceren. De uiteindelijke briket van honingraatkolen heeft de volgende vormen en maten:

- Vormen: rond, cilindrisch, vierkant, rechthoekig, veelhoekig, zeshoekig, waaieren vele andere vormen.

- Maten: afhankelijk van de vorm en de machinale mal.

Daarnaast kan deze machine ook kolenstokken produceren, zoals hieronder weergegeven.

Structuur van de machine voor het maken van honingraatbriketten

De machinestructuur bestaat uit het machinelichaam, transmissie, invoer, stempelen en afvoer (met riem).

Het is gemakkelijk te begrijpen en te bedienen. Als u meer informatie wilt, neem dan gerust contact met ons op.

Hoe honingraathoutskool maken?

Het werkingsprincipe van de honingraatkolenbriketmachine is om de katrol door de motor aan te drijven, die op zijn beurt de hele machine aandrijft.

Het gebruikt de methode van twee stempelen, de eerste wordt gevormd en de tweede wordt uit de vorm gehaald. Hierdoor wordt de kwaliteit van eindproducten gewaarborgd.

Het proces van het maken van honingraatkoolbriketten is heel eenvoudig en de stappen zijn als volgt:

- Doe houtskoolpoeder of kolenpoeder in de trechter.

- Start de machine en de machine begint te werken.

- Het stempelgedeelte werkt en drukt het poeder in de mal om steenkoolbriketten te vormen. Na het vormen opnieuw stempelen om uit de vorm te komen.

- De honingraatkolenbriket wordt één voor één afgevoerd. Het hele proces is voltooid.

Waarom honingraatkolenbriketten gebruiken?

Omdat de honingraatkolenbriket de volgende voordelen heeft:

- Hoge dichtheid

- Ontvlambaar

- Lange brandtijd

- Niet giftig

- Rookvrij

Toepassing van honingraatbriketmachine

De grondstoffen voor de Shuliy-honingraatkolenbriketmachine zijn poederachtig, daarom wordt de machine veel gebruikt in industrieën, zoals:

- Kolen

- Energie

- Verwarming

- Vervoer

- Metallurgie

- Cement

- Gebouw

Hoe zit het met de prijs van de kolenbriketmachine?

De prijs van een honingraatbriketmachine wordt beïnvloed door verschillende factoren, waaronder capaciteit, configuratie, vraag en aanbod op de markt, after-sales service, kwaliteit van de apparatuur en merkreputatie.

Als u meer wilt weten, raden wij u aan contact met ons op te nemen. Onze professionele managers zullen u een gedetailleerde prijs bezorgen.

Exporteer Shuliy honingraatbriketmachine naar verschillende landen

De honingraat kolen brikettenmachine van Shuliy Machinery is met succes in verschillende markten binnengekomen, zoals Oeganda, Rusland, Sri Lanka en Kazachstan.

Deze steenkoolbriketmachine is een belangrijk productiehulpmiddel geworden in de ontwikkeling van de houtskoolindustrie in deze landen en regio's.

Voor verzending verpakken wij de machine in houten kisten om schade aan de machine te voorkomen.

Wil je meer weten? Lees dan: 2 sets honingraat kolen brikettenpers naar Oezbekistan gestuurd

Onderhoud van honingraatbrikettenmachine

Om de normale werking van de machine te garanderen, heeft de kolenbriketmachine regelmatig onderhoud en reparatie nodig.

- Het transportbandgedeelte moet op de interne tandwielen worden ingevet.

- Het lagergedeelte moet worden gevuld met machineolie.

- Het onderhoud wordt met bepaalde tussenpozen uitgevoerd, bijvoorbeeld één keer per dag gedurende de eerste week. Hierna kunt u dit aanpassen naar eens per 10 of 15 dagen.

Bijenkorf koolbrikettenproductielijn

Onze honingraatkolenbriketten-productielijn is bedoeld om automatisch...

Hoe maak je honingraatkool?

Honingraatkool, een veelzijdige biobrandstof, wint snel aan populariteit…

Shuliy honingraatbrikettenpers helpt Oezbekistan de koolstofmarkt te ontwikkelen

Een energiebedrijf in Oezbekistan wordt geconfronteerd met een sterke vraag naar...

Heet product

Industriële houtversnipperaar voor het maken van houtstof

Houtvergruizer is gespecialiseerd in het versnipperen van hout…

Warmtekrimpfilmverpakkingsmachine voor houtskoolbriketten

De verpakkingsmachine voor houtskoolbriketten krimpt eigenlijk de folie door verhitting…

Verticale houtschilfermachine voor het verwijderen van schors van bomen

De houtontschiller is ontworpen om de…

Kleine schijfhoutversnipperaar voor massale houtchipsproductie

Schijfhoutversnipperaar is ontworpen om hout te versnipperen,…

Geperste houten palletmachine

Geperste houten palletmachine is voor het vervaardigen van geperste…

Barbecue houtskoolbalpersmachine

De Shuliy houtskoolballenpers is bedoeld voor het persen…

Batch-type droger voor briketten, honingraatkolen, waterpijp-houtskool

Deze houtskooldroogmachine wordt gebruikt om te drogen…

Houtspaandersmachine voor paarden- en kippenstrooisel

Houtkrulmachine is ontworpen om uniforme… te produceren

Kwantitatieve BBQ houtskoolverpakkingsmachine

BBQ-houtskool verpakkingsmachine wordt gebruikt om… te verpakken