Honeycomb briquette machine for coal pressing

Honeycomb Coal Briquette Machine | Coal Briquetting Machine

Honeycomb briquette machine for coal pressing

Honeycomb Coal Briquette Machine | Coal Briquetting Machine

Features at a Glance

Table of Contents

Our honeycomb briquette machine is specialized equipment for producing honeycomb coal by pressing charcoal powder or coal powder(dia. <1mm).

This machine can make honeycomb and hexagonal coals. It runs 45pcs per minute. For honeycomb coal, it’s one briquette per time. For hexagonal coal, it’s 3-4pcs of briquette per time.

It can use the electric motor or diesel engine as the machine power. Besides, it has a large capacity, lots of molds to replace and a long service life. Thus, the machine is popular in Uganda, Russia, Sri Lanka, Kazakhstan, etc.

Are you interested in this coal briquette machine? if yes, contact us now! We’ll design the most suitable solution to benefit your charcoal business.

Features of honeycomb coal briquette machine

- Our honeycomb briquette machine is highly efficient, with a capacity of running 45pcs per minute.

- It can make honeycomb coal and hexagonal charcoal briquette.

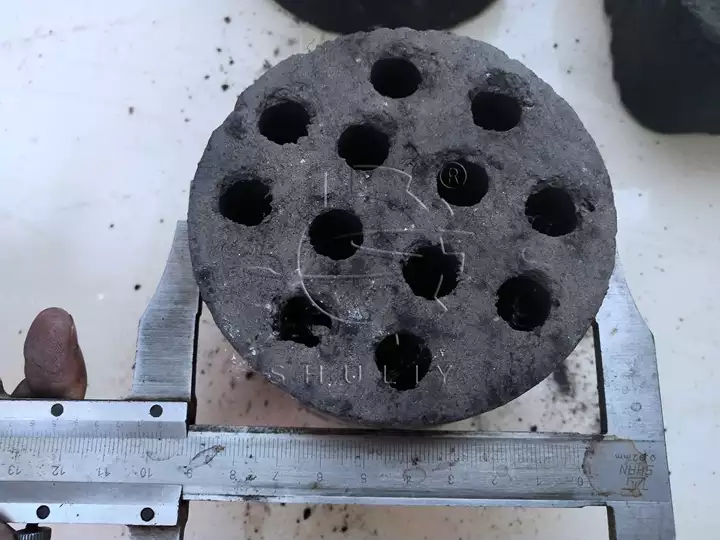

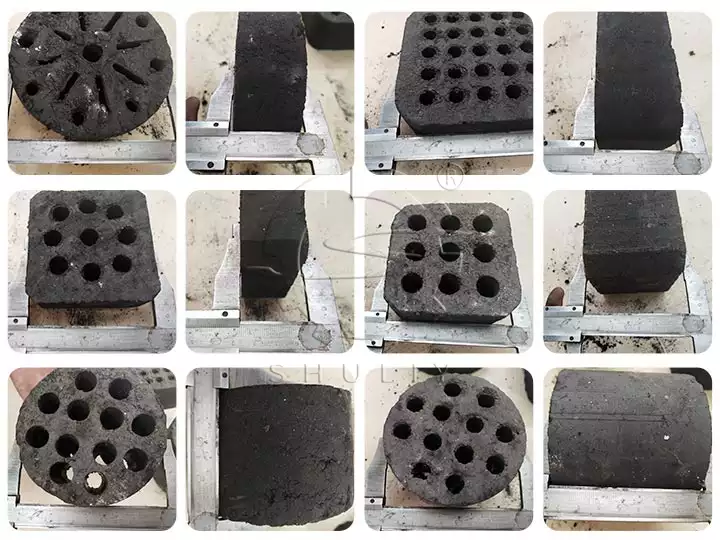

- Honeycomb coal briquette: dia. of 12.14cm, height of 7-22cm.

- Hexagonal charcoal briquette: length of 7cm, height of 7-22cm, diagonal dia. of 5cm.

- The coal briquetting machine has pre-pressing, which can produce high-density finished products.

- This machine has no accessories, is not easy to damage, and has a long service life.

- We can customize machine color, final product shape and size, machine voltage and power, etc.

Technical parameters of coal briquette making machine

| Model | SL-120 | SL-140 | SL-160 | SL-220 |

| Capacity | 45pcs/min | 45pcs/min | 45pcs/min | 45pcs/min |

| Coal diameter | φ100-φ120mm | φ100-φ140 | φ100-φ160 | φ180-φ220 |

| Coal height | 70-80mm | 70-80mm | 70-80mm | 100mm |

| Power | 7.5kw | 7.5kw | 7.5kw | 11kw |

| Shaft speed | 406rpm | 406rpm | 410rpm | 460rpm |

| Dimension | 1280 *1160*1750mm | 1320*1260*1850mm | 1400*1300*2000mm | 1580*1450*2200mm |

| Coal pressure resistance | 60-90kg | 60-90kg | 60-90kg | 60-90kg |

| Weight | 1200kg | 1400kg | 2000kg | 4000kg |

In the above table, we have described the machine model, output, power, weight, size and so on. It can be used as a reference when you choose the machine.

If you want more details, welcome to contact us now!

Moulds for honeycomb briquette machine

When using a honeycomb coal machine for coal production, molds are necessary. Different molds can produce different charcoal. The final briquette of honeycomb coal has the following shapes and sizes:

- Shapes: round, cylindrical, square, rectangular, polygonal, hexagonal, fan, and many other shapes.

- Sizes: depend on the shape and the machine mold.

Besides this, this machine can also produce coal sticks, as shown below.

Structure of honeycomb briquette making machine

The machine structure consists of the machine body, transmission, feeding, stamping and discharge(with belt).

It’s easy to understand and operate. If want details, please feel free to contact us.

How to make honeycomb charcoal?

The working principle of the honeycomb coal briquette machine is to drive the pulley through the motor, which in turn drives the whole machine.

It adopts the method of two stamping, the first one is formed and the second one is demolding. This ensures the quality of finished products.

The honeycomb coal briquettes making process is very simple, and the steps are as follows:

- Put charcoal powder or coal powder in the hopper.

- Start the machine and the machine starts to work.

- The stamping part works, pressing the powder into the mold to form coal briquettes. After molding, stamp again to demold.

- The honeycomb coal briquette is discharged one by one. The whole process is completed.

Why use honeycomb coal briquette?

Because the honeycomb coal briquette has the following advantages:

- High density

- Flammable

- Long burning time

- Non-toxic

- Smoke-free

Application of honeycomb briquette machine

The raw materials for Shuliy honeycomb coal briquette machine are powdery, thus, the machine is widely used in industries, like:

- Coal

- Energy

- Heating

- Transportation

- Metallurgy

- Cement

- Building

What about the coal briquette machine price?

The price of a honeycomb briquette machine is affected by several factors, including capacity, configuration, market supply and demand, after-sales service, equipment quality and brand reputation.

If you want to know more, we suggest you contact us. Our professional managers will provide you with a detailed price.

Export Shuliy honeycomb briquette machine to various countries

Shuliy Machinery honeycomb coal briquette machine has successfully entered several markets, such as Uganda, Russia, Sri Lanka and Kazakhstan.

This coal briquetting machine has become an important production tool in the development of the charcoal industry in these countries and regions.

Before shipment, we pack the machine in wooden crates to prevent the machine from damage.

Want to know more? Please read: 2 sets of honeycomb coal briquette press sent to Uzbekistan

Maintainance of honeycomb briquette machine

In order to ensure the normal operation of the machine, the coal briquetting machine needs regular maintenance and repair.

- The conveyor belt part needs to be greased on the internal gears.

- The bearing part needs to be filled with machine oil.

- Maintenance is carried out at specified intervals, such as once a day for the first week. After this, you can adjust it to once every 10 or 15 days.

Honeycomb coal briquette production line

Our honeycomb coal briquette production line is to automatically make…

How to make honeycomb coal?

Honeycomb coal, a versatile biomass fuel, is rapidly gaining popularity…

Shuliy honeycomb briquette press helps Uzbekistan develop charcoal market

An energy company in Uzbekistan is facing strong demand for…

Hot Product

Sawdust briquette machine for Pini Kay briquettes making

Sawdust briquette machine is to press wood chips,…

Flat die feed pellet machine for animal feed making

Feed pellet machine is designed to produce high-quality…

Barbecue charcoal ball press machine

Shuliy charcoal ball press machine is for pressing…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Honeycomb briquette machine for coal pressing

Our honeycomb briquette machine is specialized equipment for…

Industrial pallet crushing machine for sale

Waste wood crusher machine is designed for processing…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…