Wie stellt man aus Holzabfällen Sägemehlbriketts her?

Inhaltsverzeichnis

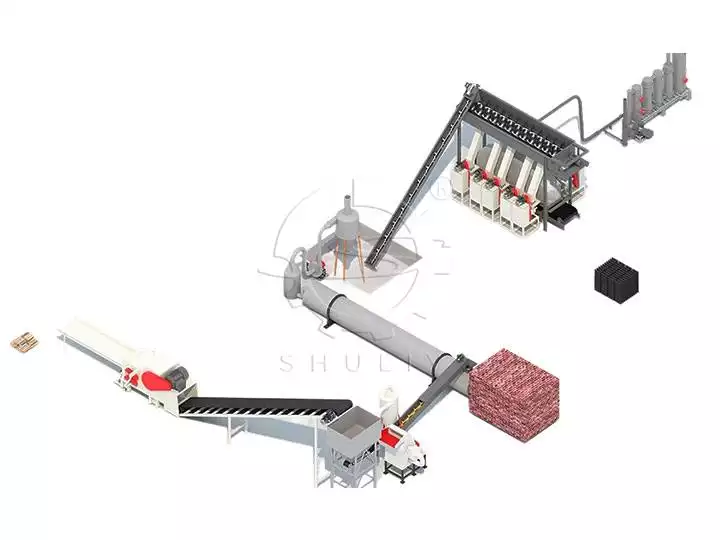

Da das Umweltbewusstsein weiter wächst, gewinnen innovative Wege, Altholz in effiziente Sägemehlbriketts umzuwandeln, an Aufmerksamkeit. Shuliy's Sägemehlbrikettmaschine ist die treibende Kraft hinter dieser grünen Revolution und hilft Ihnen, Sägemehlabfälle in nützliche Öko-Briketts zu verwandeln.

Schritt zur Herstellung von Sägemehlbriketts aus Holzabfällen

Sammlung von Sägemehlabfällen

Bevor Sie mit der Arbeit beginnen, müssen Sie Holzabfälle, den Rohstoff, aus dem Sie Sägemehlziegel herstellen möchten, sammeln, um die Abfälle wiederzuverwenden.

Vorverarbeitung des Rohmaterials

Abhängig vom Material, das in der Sägemehlpressmaschine verwendet werden soll, muss das Sägemehl normalerweise getrocknet werden und einen Feuchtigkeitsgehalt von weniger als 10 % oder zwischen 10% und 12% aufweisen. Darüber hinaus muss das Rohmaterial ggf. zerkleinert und wiederaufbereitet werden, um sicherzustellen, dass es für den Produktionsprozess der Biomassebrikettherstellung geeignet ist.

Herstellung von Pini Kay-Briketts

Dies ist der Schlüssel zur Herstellung von Biomasse-Stäbchen. Nach hohen Temperaturen presst unsere Holzbrikettmaschine das behandelte Sägemehl zu hochdichten Sägemehlbriketts ohne Zusätze.

Trocknen und Verpacken

Die geformten Sägemehlbriketts durchlaufen einen kurzen Trocknungsprozess. Danach können sie entsprechend Ihren Anforderungen verarbeitet werden. Wenn Sie sie verkaufen möchten, können Sie sie sorgfältig verpacken, um die Qualität und das Aussehen des Produkts sicherzustellen.

Maschine zur Herstellung von Holzbriketts

Die Maschine, die die Produktion von Biomasse-Stäbchen ermöglicht, wird als Holzbrikettmaschine bezeichnet. Shuliys Holzbrikettmaschine ist das Herzstück dieses Umwandlungsprozesses. Ihre effiziente Stäbchenproduktionskapazität, die einstellbare Produktionskapazität und die Anpassungsfähigkeit an verschiedene Rohmaterialien erleichtern Ihnen die Umwandlung von Sägemehlabfällen in Biomassebriketts.

Kommen Sie zusammen zum Altholzrecycling!

Möchten Sie Einnahmen aus Altholz generieren? Kontaktieren Sie uns und wir helfen Ihnen dabei, die für Ihre Bedürfnisse am besten geeignete Option zum Recycling und zur Wiedergewinnung von Holz zu empfehlen!