おがくず練炭作りに添加剤は必要ですか?

目次

答えは「ノー」です。環境保護の概念の普及と技術の進歩に伴い、おがくず練炭は再生可能な燃料資源として注目を集めています。

しかし、製造プロセス中に添加剤を追加する必要があるかどうかは、多くの潜在的な顧客や投資家にとって懸念事項となっています。当社の高度なバイオマスブリケット製造機技術と合わせて、この重要な問題について分析します。

おがくず練炭を無添加で作る理由

おがくず成形機を使用して、添加剤を必要とせずにピニカイ練炭を製造します。その理由は次のとおりです。

自然な結合特性

高品質のバイオマス原料(木材チップ、もみ殻、トウモロコシの穂軸など)には、一定の割合でリグニンが含まれています。リグニンは、高温圧縮プロセス中に天然バインダーとして使用できる天然樹脂です。追加の化学合成材料を追加します。

環境および経済的考慮事項

添加剤を使用しないことで、潜在的な環境汚染問題を回避し、生産コストを削減できるため、バイオマスロッドの市場競争力が高まり、環境に優しい無公害製品を求める現代の消費者のニーズにも応えられます。

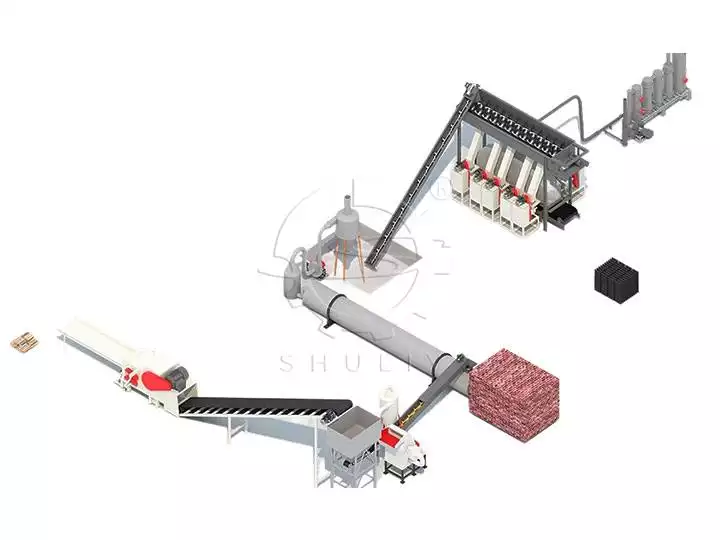

バイオマスブリケットの製造工程

- 粉砕:バイオマス素材をロッドの製造に適したサイズに粉砕します。

- 乾燥:粉砕したバイオマス材料を適切な含水率まで乾燥させます。 おがくず乾燥機.

- 形にする: 効率的なバイオマスロッドの形状を形成します。 おがくず丸太製造機.

無添加バイオマス練炭機のお見積り受付中!

無添加プロセスを使用しておがくずブリケットの製造に関心のあるお客様には、カスタマイズされたバイオマス粉砕装置、エネルギー効率の良いバイオマスブリケット製造機、および関連する補助サービスを含むワンストップソリューションを提供しています。

ご連絡いただくだけで、お客様の特定のニーズに応じた詳細なプロジェクト計画と正確な見積り情報を提供いたします。