Zaagselbrikettenmachine voor het maken van Pini Kay-briketten

Biomassabrikettenmachine | Pini Kay brikettenmachine

Zaagselbrikettenmachine voor het maken van Pini Kay-briketten

Biomassabrikettenmachine | Pini Kay brikettenmachine

Kenmerken in één oogopslag

Inhoudsopgave

Shuliy zaagsel briketmachine (biomassa briketmachine) kan houtsnippers, zaagsel, houtkrullen, rijstkaf, etc. persen tot briketten als brandstof, met een capaciteit van 250-350 kg/u.

Met hoge druk en temperatuur kan onze zaagselbrikettenmachine briketten maken met dia. van 40-50 mm in zeshoekige en vierkante vormen, zonder enige verslavende werking.

Als u op zoek bent naar een oplossing voor het recyclen van uw houtzaagsel, dan is de Shuliy Pini Kay-brikettenmachine de ideale uitrusting voor u!

Inleiding tot de Shuliy-zaagselbriketmachine

De Shuliy biomassabriketmachine is een professionele extruderapparatuur die voornamelijk wordt gebruikt om grondstoffen zoals hout, houtsnippers, bamboe, enz. Te verwerken en in stokken met gaten te drukken.

De machine wordt gekenmerkt door hoge efficiëntie en precisie en kan briketten met een stabiele kwaliteit produceren, die veel worden gebruikt in houtbewerking, meubelproductie, bouwdecoratie en andere industrieën.

Voordelen van zaagselbriketpers

- Capaciteit van 250-350kg/u: Machine voor het maken van zaagselbriketten kan grondstoffen zoals hout en houtsnippers op een snelle en continue manier verwerken, wat de productie-efficiëntie verbetert en tijd en arbeidskosten bespaart.

- Zaagselbriketdichtheid van 1-1,3t/m³: De biomassabriketmachine kan de grondstoffen in uniforme maten en vormen van houten staven persen, waardoor de consistentie en nauwkeurigheid van de productkwaliteit wordt gegarandeerd.

- Voeding elektrische motor: Deze zaagselbrikettenmachine verbruikt minder energie, vermindert energieverspilling en voldoet aan de eisen van milieubescherming.

- Intelligent bedieningspaneel: Eenvoudig en gemakkelijk te bedienen, wat handmatige tussenkomst vermindert en de productie-efficiëntie verbetert.

- Meerdere toepasbare grondstoffen: Hout, houtsnippers, houtkrullen, rijstschillen, bamboe, enz.

- Flexibel maatwerk: De zaagselbrikettenmaker kan worden aangepast met verschillende specificaties en maten stokjes, afhankelijk van de behoeften van de klant, en past zich aan verschillende scenario's en toepassingen aan.

Technische parameters van zaagselbriketmachine te koop

We hebben het veel verkochte model van de houtzaagselbrikettenmaker, namelijk de SL-50.

| Model | SL-50 |

| Capaciteit | 250-350kg/u |

| Stroom | 18,5 kW of 22 kW |

| Dimensie | 1,7*0,7*1,4m |

| Gewicht | 700 kg |

| Verwarmingstemperatuur | 260-380℃ |

| Benodigde grondstoffen | Maat: 3-5 mm Vocht: ≤12% |

| Zaagsel briket | Diameter: 46-50 mm Binnendiameter: 10-20 mm Lengte: verstelbaar |

| Slijtagedelen | Schroef, mal en verwarmingsring |

Uit de bovenstaande tabel kunnen we leren dat er vereisten zijn voor grondstoffen. Voor soepel machinegebruik zijn de houtversnipperaar en zaagsel droger vereist.

Als u een grote output wilt, kunt u meerdere zaagselbrikettenmakers tegelijkertijd gebruiken om uw doel te bereiken.

Grondstoffen om zaagselbriketten te maken

De grondstoffen voor de biomassa briketmachine zijn berkenhout, dennenhout, beukenhout, houtsnippers, bamboesnippers, rijstkaf, pindadoppen, houtkrullen, bagasse, enz.

Eindproducten geproduceerd door een houtzaagselbriketmachine

Zaagselbriketten geproduceerd door de houtstofbriketmachine hebben een hoge consistentie en nauwkeurige afmetingen, glad oppervlak, geen bramen, stabiele en betrouwbare kwaliteit.

De zaagselstampers kunnen worden aangepast aan de eisen van verschillende industrieën.

Voordelen van zaagselbriketten

- De zaagselbriketten vatten gemakkelijk vlam, hebben een hoge calorische waarde (meer dan 20% vergeleken met gewoon hout), minder verontreinigende stoffen tijdens de verbranding.

- Biomassabriketten hebben een hoog soortelijk gewicht waardoor ze gemakkelijk op te slaan en te transporteren zijn.

- Ze kunnen het gebruik van land- en bosbouwresiduen ten volle benutten en de spanning op het gebied van land- en bosbouwenergie verminderen.

- Van houtbriketten kan zaagselbrikethoutskool worden gemaakt als natuurlijke brandstof.

Structuur van de machine voor het maken van zaagselbriketten

De machine bestaat uit een motor, schakelkast, toevoerpoort, afvoerpoort en opvangrookafdekking.

Accessoires voor Shuliy zaagselbrikettenmachine

De belangrijkste accessoires van de machine voor het maken van zaagselbriketten zijn de schroef, verwarmingsring en mal.

- Als de machine lange tijd werkt, kan de schroef enige schade vertonen en moet deze in geval van nood worden uitgerust met een spiraal.

- De mallen kunnen worden gebruikt om houtbriketten van verschillende afmetingen te produceren, afhankelijk van de behoeften van de klant.

- Omdat de zaagselbrikettenmachine onder een hoge temperatuur werkt, is ook de verwarmingsring essentieel.

Hoe werkt de Pini Kay-brikettenmachine?

Wanneer u de zaagselbrikettenmachine gebruikt, dient u de machine voor te verwarmen. De temperatuur moet 260-380 ℃ bereiken (verschillende temperaturen afhankelijk van verschillende grondstoffen).

Door spiraalextrusie, onder hoge temperatuur en hoge druk, wordt de lignine in de houtgrondstoffen geplastificeerd, zodat de microvezels worden gecombineerd tot een staafvormige vaste brandstof.

Fabrikanten van biomassabrikettenmachines

Shuliy zaagselbrikettenpersfabriek is een toonaangevend bedrijf met een rijke ervaring en uitstekende technologie.

- Met jarenlange ervaring in de productie van houtskool- en houtverwerkingsmachines hebben we een schat aan technologie en kennis opgebouwd.

- Ons R&D-team en productieteam bestaan uit professionals die voortdurend innoveren en onze producten optimaliseren om aan de behoeften van onze klanten te voldoen.

- De zaagselbrikettenmachinefabriek streeft ernaar klanten hoogwaardige producten en uitstekende service te bieden en uw betrouwbare partner te worden.

Als u op zoek bent naar een fabrikant van zaagselbrikettenmachines, is Shuliy uw beste keuze.

Verpakking en verzending van de Shuliy-machine voor het maken van zaagselbriketten

Houten kist verpakking: Om breuk te voorkomen, wordt de machine omwikkeld met een laag plastic folie en vervolgens verpakt met multiplex/triplex, dat vrij is van begassing. En de accessoires worden in de trechter geplaatst om verlies te voorkomen.

Verzending: Vóór verzending, test de houtzaagsel briketmachine en stuur de testvideo ter referentie van de klant. Na verzending, moeten de douanedocumenten, de verwachte aankomsttijd en het scheepsnummer duidelijk zijn. Herinner de klant ook een week voor de aankomsttijd.

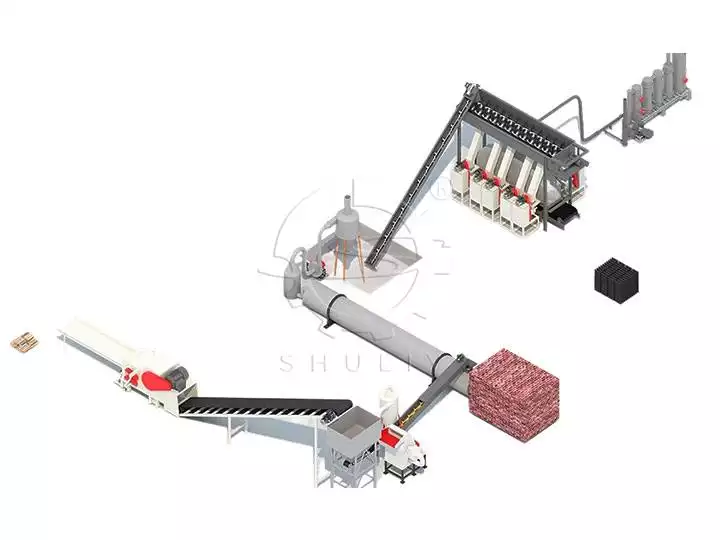

Zaagselbriket-houtskoolproductielijn

In het hele proces zijn de zaagselbrikettenmachine en de carbonisatieoven twee belangrijke schakels in de houtskoolproductielijn.

- De Pini Kay-brikettenmachine is verantwoordelijk voor het vormen van de houtsnippers tot houtskoolbriketten.

- De carbonisatie oven is verantwoordelijk voor het carboniseren van de briketten tot afgewerkte houtskool.

Concreet kunt u het volgende raadplegen:

Veelgestelde vragen over biomassabrikettenmachine

Is de lengte van de pini kay briket verstelbaar?

Ja, de positie van de stop kan worden geregeld, de lengte van de stop is 10-15 cm.

Wat is de grondstof van de zaagselbriketmachine?

Houtsnippers, rijstschillen, koffiedik/schelpen, stro, rijststro, maïskolven, bagasse, bamboechips, pindadoppen, palmbladeren, enz.

Welke mallen worden er gebruikt voor de Pini Kay-brikettenmachine?

Zes zijden met gaten, vierkant met gaten. Mallen zonder gaten zijn niet mogelijk.

Hoe zit het met de slijtdelen van de zaagselbrikettenmachine?

Slijtdelen zijn mallen, schroeven en verwarmingsringen.

Schimmel heeft een levensduur van één jaar.

De schroef heeft een levensduur van 3 maanden.

De verwarmingsring heeft een levensduur van 6 maanden.

Bij aankoop van 3 of meer zaagselbrikettenmachines kunnen wij slijtdelen leveren.

Houtskoolproductielijn voor biomassa recycling

De zaagsel-houtskoolproductielijn is ontworpen om zaagsel om te zetten, …

Weet je de prijs van de houtstofbriquettemachine?

Wanneer u een biomassa-briketmachine koopt, moet u letten op…

SL-50 biomassa briquettextruder verkocht aan Duitsland

Onlangs heeft onze Duitse klant bij ons een biomassa-briketmachine gekocht…

Houtstofbriquettemachine voor biomassa recycling

De Shuliy productielijn voor zaagselbriketten is bedoeld om biomassa materialen te persen…

SL-50 houtbriquettemachine verkocht aan Turkije

Hier zijn we zo enthousiast om te delen dat onze klant heeft gekocht…

Succesvol Pini Kay brikettenmachine naar het VK gestuurd

Voor deze klant uit het Verenigd Koninkrijk heeft hij een diepgaand…

Export van SL-50 biomassa briquettemachine naar Cambodja

We hebben succesvol samengewerkt met een fabriek in Cambodja over een…

250-300kg/h houtstofpersmachine voor de brandstofbusiness in Nigeria

In het huidige tijdperk van focus op milieubescherming en duurzaamheid…

Shuliy houtstofbriquettemachine UK: voldoet aan hoge eisen

Onze zaagsel briketmachine UK is zeer populair in…

Shuliy houtstofbriquettemachine zet houtstofafval om in winst

Zaagsel, vaak beschouwd als een vervelend bijproduct, heeft een nieuwe…

Heet product

Ronde & kubieke shisha-houtskooltabletpersmachine

Deze shisha-houtskoolmachine is bedoeld voor het efficiënt…

Houtskoolbrikettenmachine voor kolenfabriek

De houtskoolbriquettemachine wordt gebruikt om…

Batch-type droger voor briketten, honingraatkolen, waterpijp-houtskool

Deze houtskooldroogmachine wordt gebruikt om te drogen…

Verticale houtschilfermachine voor het verwijderen van schors van bomen

De houtontschiller is ontworpen om de…

Roterende waterpijpkoolstofmachine voor ronde & kubus shisha-koolstof

De ronde hukaalskool charcoal machine is speciaal bedoeld voor…

Houtskoolmachine voor de productie van kokosnootschalenhoutskool

De machine voor het maken van kokosnootschilhoutskool is ontworpen om…

Houtzaagmachine voor het zagen van logs

Houtzagerijmachine is ontworpen om bomenstammen te verwerken…

Horizontale koolstofiseringsoven voor houtskoolproductie

Horizontale carbonisatieoven wordt gebruikt om hout…

Wielmolen voor het malen en mengen van houtskoolpoeder

De houtskoolpoedermixer wordt gebruikt voor het mengen en…