Laini ya uzalishaji wa briketi za vumbi kwa ajili ya kuchakata majani

Sawdust Briquette Press | Mashine ya Briquette ya Biomass

Laini ya uzalishaji wa briketi za vumbi kwa ajili ya kuchakata majani

Sawdust Briquette Press | Mashine ya Briquette ya Biomass

Jedwali la Yaliyomo

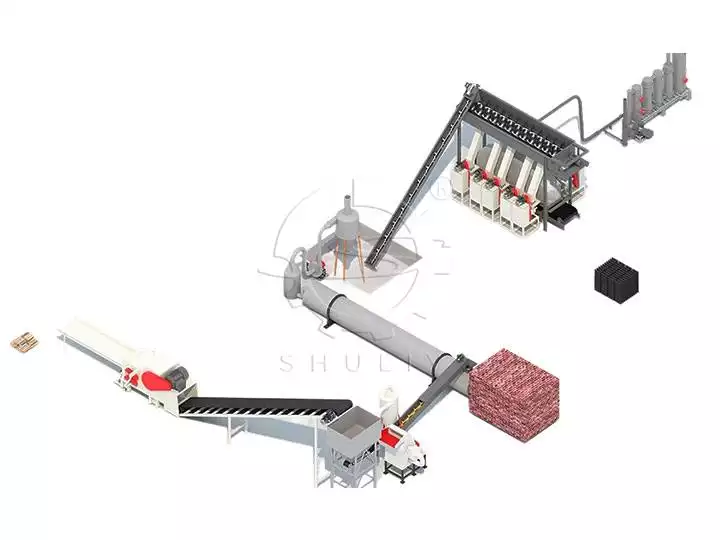

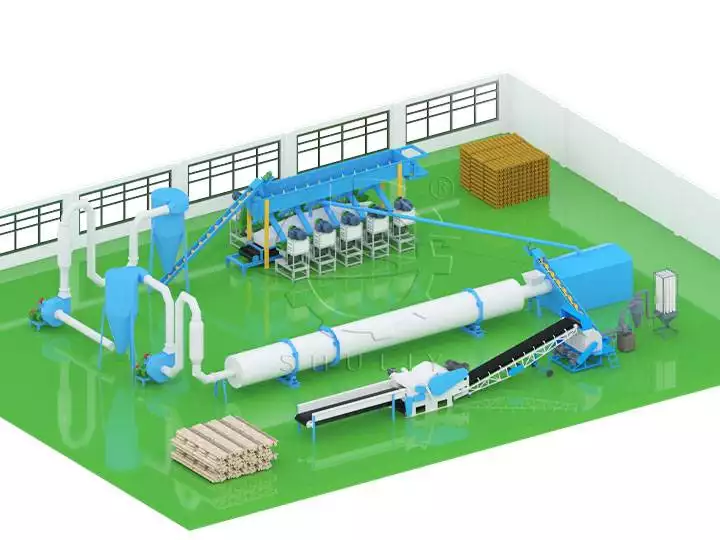

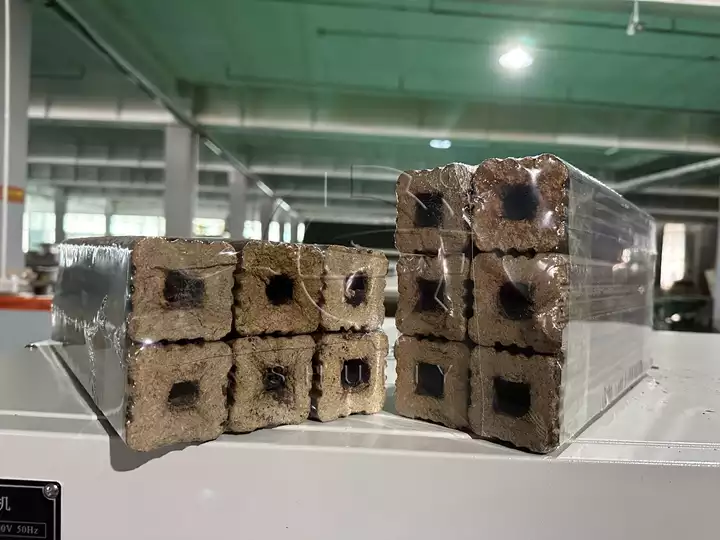

Mstari wa uzalishaji wa briketi za vumbi la mbao wa Shuliy unalenga kusukuma malighafi ya biomasi kama vile vumbi la mbao, vipande vya mbao, nyasi, maganda ya mpunga, na kadhalika, kuwa briketi zenye mashimo. Bidhaa za mwisho zinaweza kutumika kama mafuta, inapokanzwa, au kutengeneza makaa ya briketi za vumbi la mbao.

Mashine moja ya briquette ya machujo ina uwezo wa 250kg/h. Ikiwa unataka uwezo mkubwa, suluhisho ni kutumia mashine kadhaa za pini kay briquette.

Malighafi kwa ajili ya uzalishaji wa briketi za majani

Nyenzo mbichi zinazotumika kwa ajili ya mstari wa kutengeneza briketi za vumbi la mbao zinajumuisha vumbi la mbao, vipande vya mbao, makunyanzi ya mbao, maganda ya mpunga, nyasi, vipande vya mianzi, mabaki ya miwa, maganda ya karanga, n.k.

Mahitaji ya malighafi yameorodheshwa hapa chini.

- Ukubwa: 3-5 mm.

- Unyevu: ≤12%.

Baada ya briqutting, briquettes ya sawdust hutumiwa sana katika joto la kaya, mafuta ya viwanda, barbeque na mashamba mengine.

Mchakato wa kutengeneza briquettes za sawdust

Baada ya kuelewa malighafi, hebu tuangalie jinsi ya kuzalisha kwa kiasi kikubwa briquettes ya majani.

Hatua ya 1: kusagwa

Kwa sababu ya malighafi yenye ukubwa mkubwa, aina hii ya kisaga cha nyundo hutumiwa kusaga na kuponda malighafi ya mbao kuwa vumbi la mbao la 3-5mm.

Hatua ya 2: kukausha

Baada ya kusaga, vumbi la mbao lina kiasi fulani cha maji, kwa hivyo, mashine ya kukaushia vumbi la mbao inahitajika kwa ajili ya mchakato huu. Inapaswa kukausha vumbi la mbao na unyevu wa ≤12%.

Hatua ya 3: briquetting

Kisha, vumbi la mbao huenda kwenye mashine ya kusukuma briketi za vumbi la mbao ili kutoa briketi za pini-kay zilizoundwa.

Hatua ya 4: ufungaji

Hatimaye, tumia mashine ya kupakia kwa filamu ya kukunjamana kupakia briketi za vumbi la mbao. Aina hii ya pakiti ni rahisi kuhifadhi na kusafirisha.

Faida za mstari wa uzalishaji wa pini-kay briquettes

- Pato la>250kg/h. Mstari huu wa uzalishaji wa briketi za mbao una uwezo wa chini wa 250kg/h. Ikiwa unahitaji uwezo mkubwa, tumia tu mashine ya briquette ya vumbi zaidi.

- Briqutting machujo ya mbao, chips mbao, maganda ya mchele, nk. Mstari huu unaweza kusindika machujo ya mbao, mbao, mabaki ya kilimo na wengine, kutoa kubadilika katika uchaguzi wa malighafi.

- Kubinafsisha. Tunaweza kubinafsisha suluhisho bora zaidi la kutengeneza briquette ya vumbi kulingana na bajeti yako na mahitaji ya pato.

Vifaa kwa ajili ya mstari wa uzalishaji wa briquettes ya sawdust

Kwa sababu mstari wa uzalishaji unajumuisha vifaa tofauti, vifaa vya mashine tofauti havija umbo sawa, kama vile:

- Kinu cha nyundo: vile na skrini.

- Vyombo vya habari vya briquette ya sawdust: pete za kupokanzwa, screws, na molds.

Unaponunua mstari wa uzalishaji wa briquette ya sawdust, unaweza kuomba vifaa zaidi kwa dharura. Na tutakupa kwa bei nzuri.

Kwa nini uchague Shuliy kama muuzaji wa laini ya kutengeneza briketi za mbao?

- Imara na ya kuaminika ya ubora wa vifaa.

- Tunatumia vifaa vya hali ya juu na teknolojia ya hali ya juu ili kuhakikisha utendakazi thabiti wa muda mrefu wa mashine ya briquette ya majani.

- Huduma kamili baada ya mauzo.

- Shuliy hutoa huduma kamili kama vile usakinishaji na uagizaji, mafunzo ya kiufundi na matengenezo ya vifaa ili kuhakikisha kuwa wateja hawana wasiwasi.

- Huduma iliyobinafsishwa.

- Kulingana na mahitaji mahususi ya wateja, tunatoa masuluhisho yaliyoundwa mahususi ili kukidhi mahitaji tofauti ya uzalishaji.

- Sifa nzuri ya mteja.

- Kwa vifaa vya ubora wa juu na huduma bora, tumeshinda uaminifu na sifa za wateja wetu.

Jinsi ya kupata suluhisho maalum?

Kwa kufuata hatua hizi rahisi, utapokea suluhisho la uzalishaji lililoundwa kulingana na mahitaji yako ya kuchakata tena biomasi.

- Wasiliana nasi: wasiliana nasi kwa WhatsApp/WeChat/tel, barua pepe au uchunguzi wa mtandaoni.

- Tuambie mahitaji yako: tupe mahitaji yako ya uzalishaji, ikijumuisha taarifa kuhusu pato linalotarajiwa, bajeti, aina za malighafi, n.k.

- Suluhisho la kubuni: kulingana na mahitaji yako, timu yetu ya wataalamu itakutengenezea suluhisho la kibinafsi, ikiwa ni pamoja na uteuzi wa vifaa na mtiririko wa mchakato.

- Malipo: suluhu ikishakamilika, unapaswa kulipa amana au ufanye malipo kamili (kama ilivyojadiliwa).

- Uzalishaji: basi, tutaanza uzalishaji wa vifaa ili kuhakikisha utoaji wa wakati wa bidhaa za ubora.

- Usafirishaji: baada ya uzalishaji wa vifaa kukamilika, tutapanga usafiri ili kuhakikisha kuwa vifaa vinatolewa kwako kwa njia salama na kwa wakati.

Imekamilika kupeleka mashine ya Pini kay briquettes nchini Uingereza

Kwa mteja huyu kutoka Uingereza, ana uelewa mkubwa…

Je, nyongeza ni muhimu katika kutengeneza briquettes za vumbi la mbao?

Jibu ni HAPANA. Kwa kuenea kwa ulinzi wa mazingira...

Bricks za vumbi la mbao zinatumiwa kwa ajili gani?

Matofali ya pumba ya mbao ni aina ya nishati rafiki kwa mazingira na yenye ufanisi...

Je, unawezaje kutengeneza briquettes za vumbi la mbao kutoka kwa taka za mbao?

Kama vile uelewa wa mazingira unavyoendelea kukua, njia bunifu za kubadilisha…

Mashine yetu ya briquette ya vumbi la mbao Uingereza inaongoza mwelekeo wa mafuta ya biomasi

Nchini Uingereza, mahitaji ya nishati ya biomasi yameongezeka kama...

Mashine ya kupiga vumbi la mbao inayouzwa kwenda Uganda kubadilisha vigae vya mbao kuwa briquettes

Mteja mmoja kutoka Uganda alikumbana na kiasi kikubwa cha...

Export mashine ya kutengeneza brick za vumbi la mbao kwenda Indonesia

Mteja kutoka Indonesia alikuwa kwenye biashara ya taka za mbao…

Mashine ya kutengeneza vipande vya sawdust na mashine ya kubana makaa ya mawe iliyotumwa Kanada

Hivi karibuni, mmoja wa wateja wetu kutoka Kanada alichagua kununua...

Usafirishaji wa extruder ya briquette ya biomass kwenda Bulgaria

Our Bulgarian client operates a wood waste recycling plant with…

Mashine ya kubana unga wa mbao kwa ajili ya kutengeneza briquettes za Pini Kay

Mashine ya kutengeneza briquette ya sawdust ya Shuliy (mashine ya briquettes za mimea) inaweza kubinya vipande vya mbao,…

Bidhaa Moto

Mashine ya makaa ya hookah ya mzunguko kwa shisha ya mduara na ya mraba

Mashine ya mkaa ya rotary hookah ni maalum kwa…

Gari la gurudumu kwa kusaga na kuchanganya unga wa makaa

Mchanganyaji wa unga wa mkaa hutumika kuchanganya na…

Mashine ya kupakia pellet ya mrija wa mwelekeo kwa ajili ya kutengeneza chakula cha wanyama

Máy ép viên thức ăn được thiết kế để sản xuất…

Milling ya Raymond kwa ajili ya kusaga unga wa makaa

Máy nghiền Raymond để nghiền và xay than củi…

Mashine ya kutengeneza makaa kwa kiwanda cha makaa

Máy làm viên than hoạt tính dùng để làm…

Kisafishaji cha nyundo cha viwanda kwa kusaga mbao

El molino de madera con martillos sirve para moler ramas de madera,…

Mashine ya kukausha kwa mzunguko kwa ajili ya briquettes, makaa ya nyundo, makaa ya hookah

Mashine hii ya kukaushia mkaa hutumika kukaushia…

Kiwanda cha makaa cha kuendelea kwa ajili ya kuuza

Tanuru inayoendelea ya uwekaji kaboni hutumiwa haswa kubadilisha…

Mashine ya kubana makaa ya shisha ya majimaji

Mashine hii ya kubana mkaa wa shisha ni kwa ufanisi…