Sawdust briquettes production line for biomass recycling

Sawdust Briquette Press | Biomass Briquette Machine

Sawdust briquettes production line for biomass recycling

Sawdust Briquette Press | Biomass Briquette Machine

Table of Contents

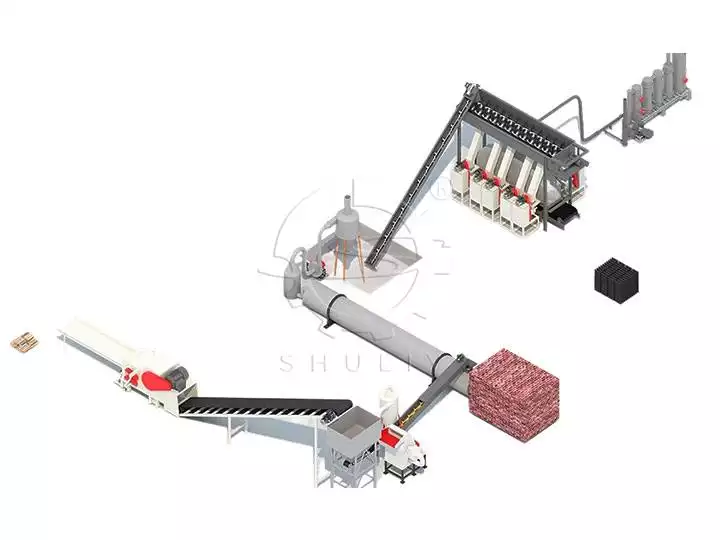

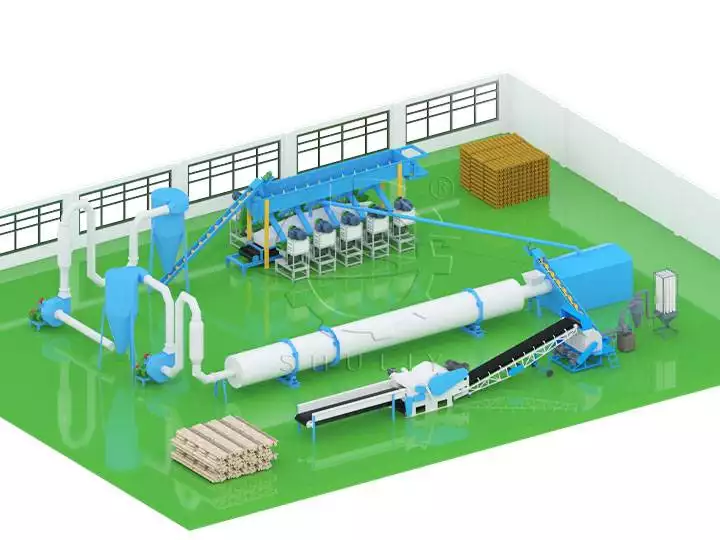

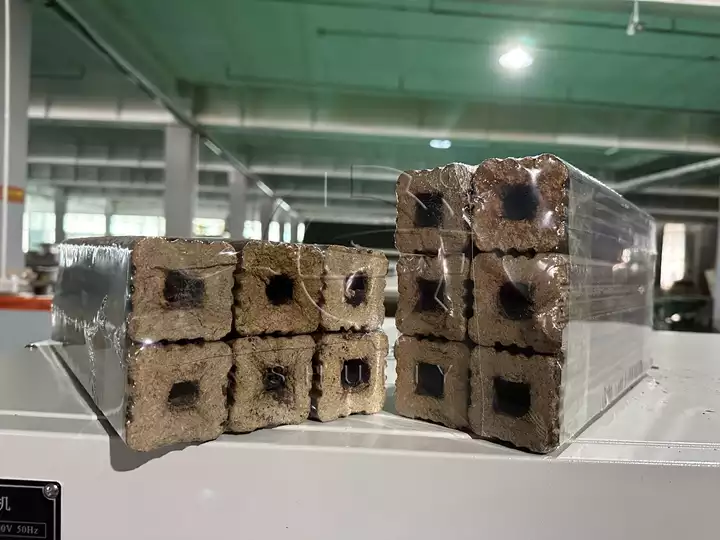

Shuliy sawdust briquettes production line is to press biomass materials such as sawdust, wood chips, straw, rice husk and so on into hollow briquettes. The final products can be used as fuel, heating or sawdust briquette charcoal making.

One sawdust briquette machine has a capacity of 250kg/h. If you want a big capacity, the solution is to use several pini kay briquette machines.

Raw materials for biomass briquettes production

The raw materials used for sawdust briquette making line include sawdust, wood chips, wood shavings, rice husks, straws, bamboo chips, sugarcane bagasse, peanut shells, etc.

Requirements for the raw materials are listed below.

- Size: 3-5mm.

- Moisture: ≤12%.

After briqutting, the sawdust briquettes are widely used in household heating, industrial fuel, barbecue and other fields.

Process of making sawdust briquettes

After understanding the raw material, let’s take a look at how to massively produce biomass briquettes.

Step 1: crushing

Because of the raw materials with the big sizes, this kind of hammer mill grinder is used to crush and grind the wood materials into 3-5mm sawdust.

Step 2: drying

After grinding, the sawdust has a certain of water, thus, a sawdust drying machine is required for this process. It should dry sawdust with a moisture of ≤12%.

Step 3: briquetting

Then, the sawdust comes to the sawdust briquette press to extrude the shaped pini kay briquettes.

Step 4: packaging

Finally, use the shrink film packing machine to package sawdust briquettes. This kind of package is easy to store and transport.

Advantages of pini-kay briquettes production line

- Output of >250kg/h. This sawdust briquettes production line has a minimum capacity of 250kg/h. If you need a large capacity, just use more sawdust briquette machine.

- Briqutting sawdust, wood chips, rice husks, etc. This line can process sawdust, wood chips, agricultural residues and others, providing flexibility in the choice of raw materials.

- Customization. We can customize the best solution for sawdust briquette making according to your budget and output requirements.

Accessories for sawdust briquettes production line

Because the production line is composed of different equipment, the accessories of different machines are not shaped the same, such as:

- Hammer mill: blades and screens.

- Sawdust briquette press: heating rings, screws, and molds.

When you buy the sawdust briquette production line, you can ask for more accessories for an emergency. And we will provide you with a good price.

Why choose Shuliy as wood sawdust briquettes production line supplier?

- Stable and reliable equipment quality.

- We use high-quality materials and advanced technology to ensure the long-term stable operation of the biomass briquette machine.

- Perfect after-sales service.

- Shuliy provides a full range of services such as installation and commissioning, technical training and equipment maintenance to ensure that customers have no worries.

- Customized service.

- According to the specific needs of customers, we provide tailor-made solutions to meet different production requirements.

- Good customer reputation.

- With high-quality equipment and excellent service, we have won the trust and praise of our customers.

How to get a customized solution?

Following these simple steps, you will receive a production solution tailored to your biomass recycling needs.

- Contact us: get in touch with us by WhatsApp/WeChat/tel, email or online inquiry.

- Tell us your requirements: provide us with your production needs, including information on expected output, budget, raw material types, etc.

- Design solution: according to your needs, our professional team will design a personalized solution for you, including equipment selection and process flow.

- Payment: once the solution is finalized, you should pay a deposit or make a full payment(as discussed).

- Production: then, we will start the production of the equipment to ensure on-time delivery of high-quality products.

- Shipment: after the equipment production is completed, we will arrange transportation to ensure that the equipment is delivered to you in a safe and timely manner.

Successfully send Pini kay briquettes machine to the UK

For this customer from the UK, he has a deep…

Is additive necessary for sawdust briquettes making?

The answer is NO. With the popularization of environmental protection…

What are sawdust bricks used for?

Sawdust bricks are a kind of environmentally friendly and efficient…

How do you make sawdust briquettes from wood waste?

As environmental awareness continues to grow, innovative ways of transforming…

Our sawdust briquette machine uk leads biomass fuel trend

In the UK, demand for biomass fuels has increased as…

Sawdust press machine for sale to Uganda to convert wood chips into briquettes

A Ugandan client was faced with a large amount of…

Export sawdust brick making machine to Indonesia

The Indonesian client was in the business of wood waste…

Sawdust briquette machine for Pini Kay briquettes making

Shuliy sawdust briquette machine(biomass briquette machine) can press wood chips,…

SL-50 wood briquette making machine sold to Turkey

Here we're so excited to share that our client bought…

Export of SL-50 biomass briquette press to Cambodia

We successfully co-operated with a factory in Cambodia on a…

Hot Product

Compressed wood pallet machine

Compressed wood pallet machine is for manufacturing compressed…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Charcoal briquette making machine for coal plant

Charcoal briquette making machine is used to make…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

This charcoal dryer machine is used to dry…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…

Wood shaving machine for horse, chicken bedding

Wood shavings machine is designed to produce uniform…

Hydraulic shisha charcoal press machine

This shisha charcoal press machine is to efficiently…

Raymond mill for charcoal powder grinding

Raymond mill is to crush and grind charcoal…