Sägemehlformmaschine und Holzkohleballpresse nach Kanada gesendet.

Inhaltsverzeichnis

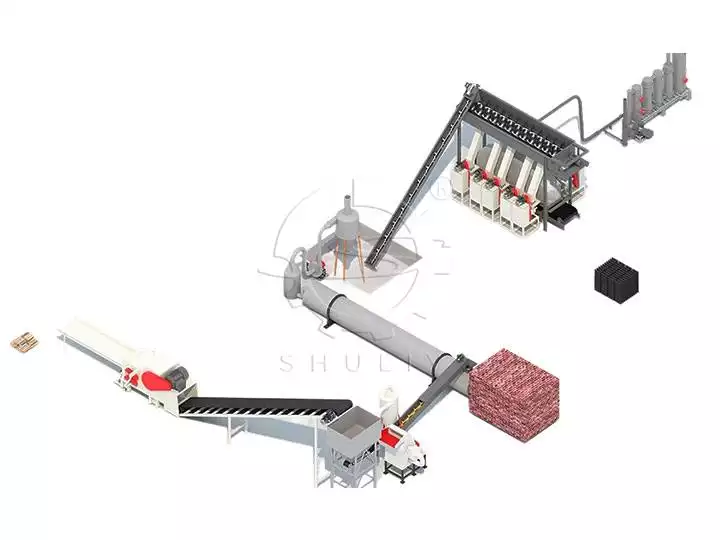

Kürzlich hat sich einer unserer kanadischen Kunden dafür entschieden, eine Sawdust-Molding-Machine zu kaufen und Kohlepresse-Ausrüstung von Shuliy zu erwerben, um aktiv an der Holzkohle-Verarbeitungsbranche teilzunehmen. Sie wird verwendet, um die Verarbeitung und den Verkauf lokaler Holzkohleprodukte durchzuführen. Im Folgenden finden Sie die Details dieser Zusammenarbeit.

Kundenhintergrund

Der Kunde befindet sich in Kanada und betreibt unabhängig ein Unternehmen zur Holzrecycling und -verarbeitung. Er verfügt über reichlich Rohstoffressourcen, darunter Sägemehl, Holzspäne, Abfälle und so weiter.

Da die lokale Marktnachfrage nach umweltfreundlicher Holzkohle (für Barbecues, Outdoor-Camping usw.) wächst, entscheidet der Kunde, in eine kleine Sawdust-Briquetting-Maschine und eine Holzkohle-Ballproduktionsmaschine zu investieren, um den Verkauf von fertigen Holzkohlensprodukten schrittweise auszuweiten.

Gerätekonfiguration

Der kanadische Kunde kaufte gleichzeitig zwei Kernformmaschinen, die zur Herstellung verschiedener Formen von Holzkohleprodukten verwendet werden.

Sawdust-Molding-Machine

- Modell: SL-50

- Leistung: 18,5 kW

- Kapazität: 250 kg/h

- Verpackungsgröße: 1,63*0,64*1,64 m

- Maschinengewicht: 650 kg

Diese Maschine eignet sich zum Extrudieren von Sägemehl in hochdichte sechseckige oder andere Formen von Stäben, die für den Brennstoffmarkt geeignet sind.

Charcoal-Ball-Pressing-Machine

- Modell: SL-290

- Leistung: 5,5 kW

- Kapazität: 1t/h

- Gewicht: 720 kg

Es wird verwendet, um Holzkohlepulver in standardisierte runde Kugeln oder kissenförmige Briketts zu pressen, die sich für die Außenheizung und industrielle Holzkohle für den lokalen Verkauf eignen.

Diese Konfiguration erfüllt die Marktpositionierungsbedürfnisse der Kunden für Holzkohleprodukte unterschiedlicher Spezifikationen, mit hoher Flexibilität und Kosten-Effektivität.

Kundenfeedback

Nachdem die Sägemehlformmaschine und die Holzkohleballpresse installiert und in Betrieb genommen wurden, gab der Kunde positives Feedback. Er sagte,

„Die Biomass Briquette-Maschine hat eine dichte Formung und die Briketts sind nicht leicht zu brechen. Die Holzkohle-Briketts, die mit der Balliermaschine hergestellt werden, weisen gleichmäßige Spezifikationen und glatte Oberflächen auf, was vollkommen dem ästhetischen Empfinden des lokalen Marktes und dem Nutzungsverhalten entspricht.“

Möchten Sie eine Holzkohleanlagenkonfiguration, die zu Ihrem Rohstoff und Budget passt? Zögern Sie nicht, uns für ein detailliertes Angebot und ein Prozessdiagramm zu kontaktieren!