Mulino a ruota per macinare e miscelare polvere di carbone

Rettificatrice per polvere di carbone | Miscelatore per macinacaffè a ruota

Mulino a ruota per macinare e miscelare polvere di carbone

Rettificatrice per polvere di carbone | Miscelatore per macinacaffè a ruota

Caratteristiche in breve

Sommario

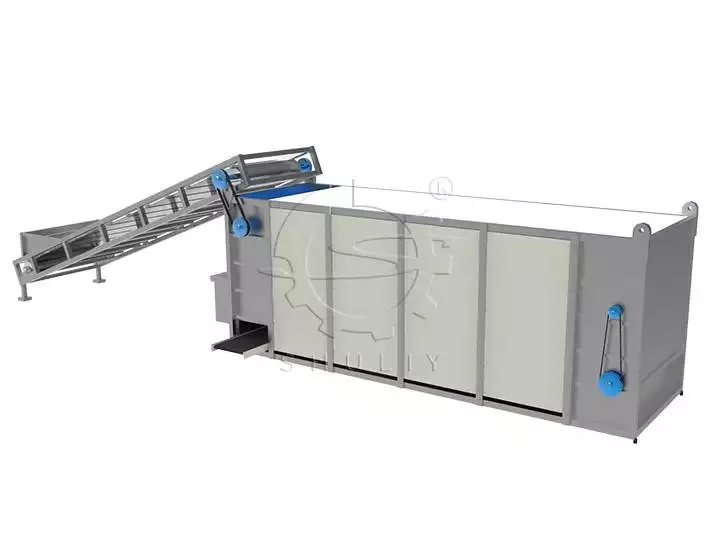

Miscelatore di polvere di carbone (conosciuto anche come mola a ruota, macchina miscelatrice di carbone, macchina di macinazione della polvere di carbone) è utilizzato per mescolare e pressurizzare la polvere di carbone, necessaria nell'impianto di lavorazione del carbone.

Può gestire polvere di carbone con una capacità di 0,3-10 t/h. È possibile scegliere l'output adatto per soddisfare le esigenze della linea di produzione del carbone.

Con un design ragionevole e un funzionamento semplice, il miscelatore smerigliatore del mulino a ruota può migliorare il tasso di utilizzo e l'efficienza produttiva della polvere di carbonio e anche ridurre il consumo di energia e i costi di produzione.

Pertanto, il mulino a ruota è una delle attrezzature chiave indispensabili nella linea di produzione del carbone.

Funzioni del miscelatore di polvere di carbone

In realtà, ci sono due funzioni della macchina miscelatrice per polvere di carbone.

- Da un lato, questa macchina mescola e mescola le materie prime (polvere di carbone) per renderle uniformi.

- D’altra parte, il miscelatore di carbone può compattare i materiali per aumentarne la densità.

Caratteristiche della macchina per miscelare polvere di carbone

- Elevata efficienza di miscelazione: Il nostro mixer per polvere di carbone è dotato di un potente meccanismo di miscelazione che garantisce una miscela accurata e uniforme di polvere di carbone, additivi e leganti.

- Tempo di miscelazione regolabile: Con durate di miscelazione personalizzabili, puoi ottenere la consistenza e la qualità di cui hai bisogno nelle tue miscele di carbone per migliorare la produttività complessiva.

- Ingombro compatto: Nonostante l'elevata capacità del mulino macinatore a ruota, il suo design compatto consente di risparmiare spazio nell'impianto di produzione, consentendo così un utilizzo efficiente di aree limitate.

Applicazioni della macchina per miscelare polvere di carbone

Si adatta a mescolare tutti i tipi di materiali secchi e umidi e materiali colloidali quali polvere di carbone, vetrificazione fango, argilla, ceneri volanti, acciaia, scorie di coda, sabbia, ecc. È ampiamente utilizzata in refrattari, ceramiche, materiali da costruzione e altre industrie.

Chiave nella linea di produzione della macchina per il carbone

Nell'impianto di lavorazione del carbone, la mola a ruota è necessaria nella linea di produzione del carbone.

Di solito viene utilizzato per macinare la polvere di carbone e, finché la materia prima è polvere di carbone, è necessaria la macchina per miscelare la polvere di carbone per mescolare e mescolare la compattazione.

Come funziona la macchina miscelatrice per polvere di carbone?

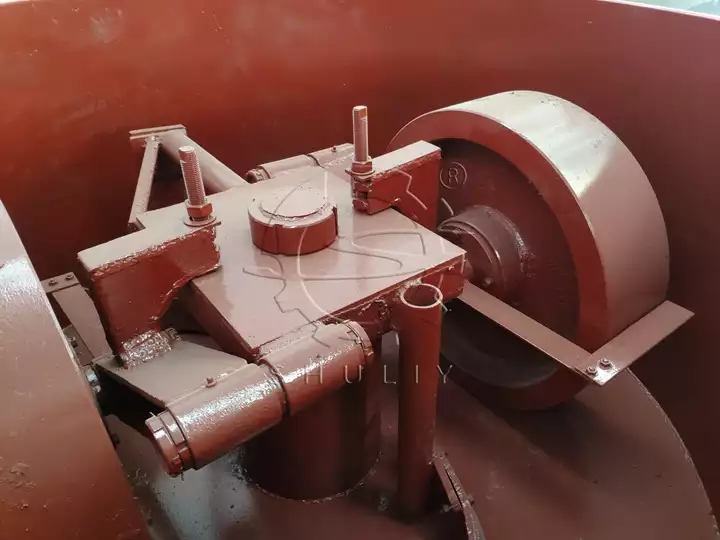

Funziona ruotando i pneumatici e facendo funzionare la macchina per mescolare uniformemente la polvere di carbone per ottenere un certo grado di uniformità e densificazione, in modo da fornire materie prime di alta qualità per il successivo processo di carbonizzazione e stampaggio.

Attenzioni quando si utilizza la rettificatrice per polvere di carbone con mulino a ruota

- Prima di avviare la macchina, verificare se le parti di trasmissione e di collegamento sono normali e se tutte le parti di fissaggio sono allentate, mancanti o rotte.

- Controllare se le parti di lubrificazione sono ben lubrificate e aggiungere e cambiare l'olio lubrificante in base ai requisiti.

- Controllare se la linea elettrica è rotta e se l'illuminazione è intatta.

- Esaminare se la tensione della cinghia del motore è adeguata, per evitare uno scivolamento eccessivo o una bruciatura eccessiva del motore.

- Quando si aggiunge materiale al mulino a ruota, l'alimentazione deve essere adeguata, in modo da non alimentare troppo materiale che ostruisca la rotazione dei rulli del mulino e danneggi l'attrezzatura.

- Alla fine di ogni turno pulire i materiali residui all'interno e all'esterno dell'attrezzatura.

Produttore e fornitore di macchine per miscelare polvere di carbone

In qualità di produttore e fornitore rispettabile di miscelatori di polvere di carbone, siamo in grado di offrire attrezzature di prim'ordine che soddisfano le diverse esigenze dei nostri clienti.

I nostri miscelatori di polvere di carbone sono economici senza compromettere le prestazioni e sono la tua prima scelta al momento dell'acquisto. Contattami se interessati!

Casi globali di miscelatori per macinatori di mulini a ruota

La nostra mola grinder mixer ha guadagnato riconoscimenti globali come parte integrante delle linee di produzione del carbone. Abbiamo esportato la nostra macchina miscelatrice di polvere di carbone in vari paesi quali Kenya, Nigeria, Indonesia, Malesia, Guatemala, ecc.

Il nostro miscelatore a ruota è un investimento importante e prezioso quando si tratta di ottimizzare la linea di produzione di carbone.

Parametri tecnici della macchina miscelatrice per polvere di carbone

| Modello | SL-1000 | SL-1200 | SL-1500 | SL-1800 | SL-2000 | SL-2500 | SL-3000 | |

| Diametro (mm) | Φ 1000 | Φ 1200 | Φ 1500 | Φ 1800 | Φ2000 | Φ 2500 | Φ 3000 | |

| Alimentazione/tempo(t) | 0.03-0.05 | 0.05-0.1 | 0.2-0.3 | 0.5-1 | 1-1.2 | 1-1.5 | 1.2-1.8 | |

| Capacità (t/h) | 0,3 t | 0,6 t-0,8 t | 1t-2t | 2t-5t | 3t-6t | 6t-8t | 8t-10t | |

| Tempo di miscelazione (volte/min) | 5-10 | 5-10 | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | |

| Potenza (kw) | 5.5 | 5.5 | 7.5 | 18.5 | 22 | 30 | 45 | |

Mietitrebbia per la macinazione di carbone di carbone

La macchina frantumatrice di carbone è una macchina multifunzionale che può…

Ruolo della macchina di macinazione della polvere di carbone nella produzione di carbone

La macchina per la macinazione della polvere di carbone, nota anche come mola a ruota…

Mola Raymond per la macinazione di polvere di carbone

La molino Raymond è efficiente per schiacciare e macinare il carbone in…

Prodotto caldo

Pressa per palline di carbone da barbecue

La pressa a sfere per carbone Shuliy serve per pressare…

Macchina di essiccazione continua per carbone da barbecue

La macchina per essiccare le briquette è usata per BBQ…

Macchina per trucioli di legno per cavalli, lettiera per polli

La macchina per trucioli di legno è progettata per produrre…

Mola a ruota per macinare e mescolare polvere di carbone

Il miscelatore di polvere di carbone è utilizzato per miscelare e…

Pressa per tavolette di carbone di narghilè rotonde e cubiche

Questa macchina per carbone per shisha è per l’efficienza…

Macchina per la produzione di blocchi di segatura di legno per blocchi di pallet di legno

La macchina per la produzione di blocchi di pallet in legno serve a…

Macchina per imballaggio a cuscino per il confezionamento di carbone per narghilè

La confezionatrice di carbone per shisha, in realtà imballaggio a cuscino…

Piccolo tritatore a disco per la produzione di grandi quantità di trucioli di legno

La cippatrice a disco è progettata per ridurre in cippato il legno,…

Macchina verticale per la pelatura del legno per la rimozione della corteccia degli alberi

La sbucciatrice di legno è progettata per rimuovere il…