Wheel mill for charcoal powder grinding and mixing

Charcoal Powder Grinding Machine | Wheel Mill Grinder Mixer

Wheel mill for charcoal powder grinding and mixing

Charcoal Powder Grinding Machine | Wheel Mill Grinder Mixer

Features at a Glance

Table of Contents

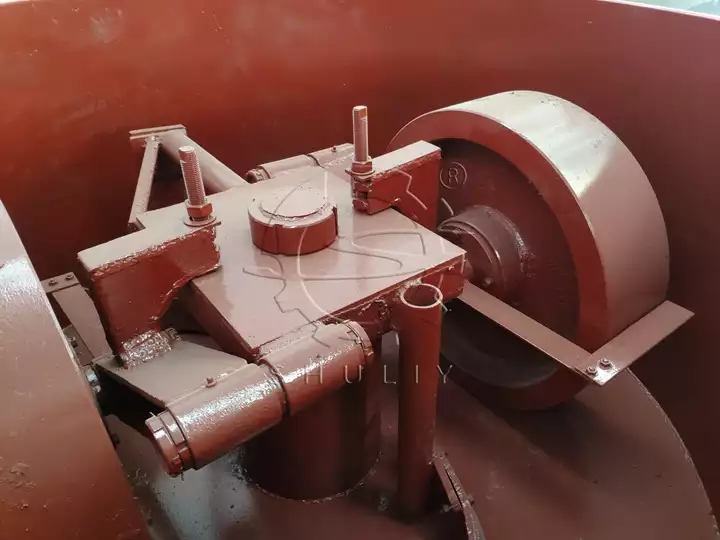

Charcoal powder mixer (also known as wheel mill, charcoal mixer machine, charcoal powder grinding machine) is used for mixing and pressurizing charcoal powder, necessary in the coal processing plant.

It can handle charcoal powder with a capacity of 0.3-10t/h. You can choose suitable output to meet your charcoal making line demands.

With reasonable design and simple operation, the wheel mill grinder mixer can improve the utilization rate and production efficiency of carbon powder, and also reduce energy consumption and production cost.

Therefore, the wheel mill is one of the indispensable key equipment in the charcoal production line.

Functions of charcoal powder mixer

Actually, there are two functions of the charcoal powder mixer machine.

- On the one hand, this machine mixes and blends the raw materials(charcoal coal powder) to make them even.

- On the other hand, the coal mixer can compact the materials to increase the material’s density.

Features of charcoal powder mixer machine

- High mixing efficiency: Our charcoal powder mixer features a powerful mixing mechanism that ensures a thorough and even blend of charcoal powder, additives and binders.

- Adjustable mixing time: With customizable mixing durations, you can achieve the consistency and quality you need in your charcoal mixtures to improve overall productivity.

- Compact footprint: Despite the high capacity of the wheel mill grinder mixer, its compact design saves space in the production facility, thus allowing for efficient utilization of limited areas.

Applications of charcoal powder mixing machine

It is adapted to mix all kinds of dry and wet materials and colloidal materials such as charcoal coal powder, refractory mud, clay, fly ash, slag, tailing slag, sand, etc. It is widely used in refractories, ceramics, building materials and other industries.

Key in the charcoal machine production line

In the charcoal processing plant, the wheel mill is necessary in the coal production line.

It is usually used to grind the coal powder, and as long as the raw material is charcoal powder, the charcoal powder blending machine is necessary to stir and mix the compaction.

How does the coal powder mixer machine work?

It works by rotating the tires and running the machine to mix the coal powder evenly to achieve a certain degree of uniformity and densification, so as to provide high-quality raw materials for the subsequent carbonization and molding process.

Attentions when using wheel mill charcoal powder grinding machine

- Before starting the machine, check whether the transmission and connection parts are normal and whether all the fastening parts are loose, missing, or broken.

- Check whether the lubrication parts are well lubricated, and add and change the lubricating oil according to the requirements.

- Inspect whether the electric line is broken and whether the lighting is intact.

- Examine whether the tightness of the motor belt is appropriate, in order to avoid too loose slipping or too tight burning of the motor.

- When adding material to the wheel mill, the feed should be appropriate, so as not to feed too much material to obstruct the rotation of the mill rollers and damage to the equipment.

- At the end of each shift, clean the residual materials on the inside and outside of the equipment.

Charcoal powder mixer machine manufacturer and supplier

As a reputable manufacturer and supplier of charcoal powder mixer, we are able to offer top-notch equipment that meets the diverse needs of our clients.

Our Charcoal Powder Mixers are economical without compromising on performance and are your first choice when purchasing. Contact me if interested!

Global cases of wheel mill grinder mixer

Our wheel mill grinder mixer has gained global recognition as an integral part of charcoal production lines. We have exported our charcoal powder mixer to various countries such as Kenya, Nigeria, Indonesia, Malaysia, Guatemala, etc.

Our wheel mill mixer is an important and valuable investment when it comes to optimizing your charcoal production line.

Technical parameters of the charcoal powder mixer machine

| Model | SL-1000 | SL-1200 | SL-1500 | SL-1800 | SL-2000 | SL-2500 | SL-3000 | |

| Dia.( mm ) | Φ 1000 | Φ 1200 | Φ 1500 | Φ 1800 | Φ2000 | Φ 2500 | Φ 3000 | |

| Feeding/time(t) | 0.03-0.05 | 0.05-0.1 | 0.2-0.3 | 0.5-1 | 1-1.2 | 1-1.5 | 1.2-1.8 | |

| Capacity( t/h ) | 0.3t | 0.6t-0.8t | 1t-2t | 2t-5t | 3t-6t | 6t-8t | 8t-10t | |

| Mixing time(times/min) | 5-10 | 5-10 | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | |

| Power( kw ) | 5.5 | 5.5 | 7.5 | 18.5 | 22 | 30 | 45 | |

Hammer mill for charcoal coal grinding

The charcoal grinder machine is a multi-functional machine that can…

Role of charcoal powder grinding machine in coal production

The charcoal powder grinding machine, also known as wheel grinder…

Raymond mill for charcoal powder grinding

Raymond mill is efficiently to crush and grind charcoal into…

Hot Product

Wood sawmill machine for log cutting

Wood sawmill machine is designed to process logs…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually heat shrink…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Sawdust block making machine for wooden pallet blocks

The wood pallet block making machine is for…

Small disc wood chipper for mass wood chips making

Disc wood chipper is designed to chip wood,…

Quantitative BBQ charcoal packing machine

BBQ charcoal packaging machine is used to package…

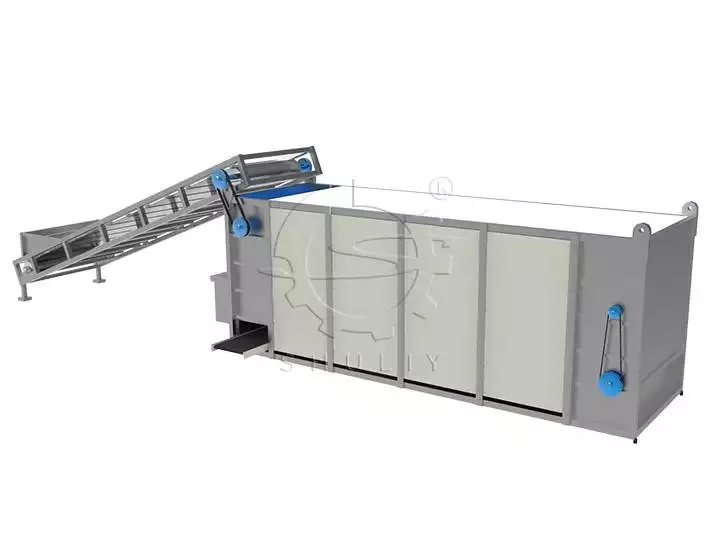

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…