機能の概要

目次

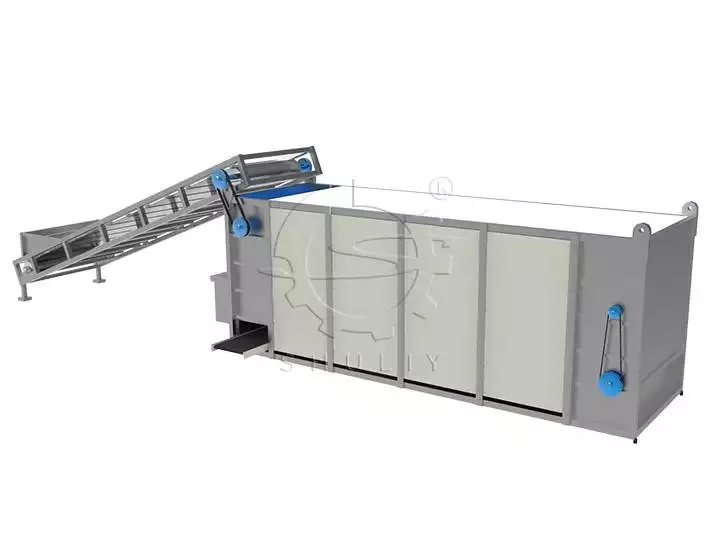

The horizontal carbonization furnace, also known as wood charcoal making machine, efficiently converts wood logs, branches, bamboo, etc. into high-quality charcoal through the carbonization process. It has a capacity of 1-3t per day.

木炭製造機のこのユニークな水平設計により、熱分布が向上し、一貫した炭化結果が得られます。

高度な制御システムにより、正確な温度とエアフロー管理が保証されます。炭の製造工程に欠かせない設備です。

Shuliy炭化炉の特徴

- 高出力:横型炭化炉は、通常1日あたり最大1〜3トンの生産量があり、大規模生産の需要を満たし、生産効率を向上させます。

- 均一な炭化:炭化炉にはサンドイッチと保温綿が装備されており、炉内の温度を均一かつ安定に保ち、炭化プロセス中に原料が完全に加熱され、炭化の均一性と高効率が保証されます。

- 多種類の原料に適用可能: Shuliy 横型炭化炉は、木材、作物の茎、果物の殻、竹などを含むさまざまな種類の材料を炭化できるため、汎用性と柔軟性が向上します。

- 環境保護と省エネ:炭化機は外部バーナーや内部加熱装置などの加熱方法を採用しており、エネルギー消費が少なく、エネルギーの無駄を減らし、環境保護の要件を満たしています。

横型炭化炉の構成部品

Mezzanine structure

Shuliy横型炭化炉はサンドイッチ構造を採用しており、炉本体の外側と内側に一定の間隔を設けてサンドイッチ空間を形成しています。

層間空間に保温綿などの保温材を充填することで、炉内温度を均一かつ安定に保つことができます。

Furnace body

炉本体は横型炭化炉の主要部分であり、通常、ある程度の密閉性と耐食性を備えた高温耐性鋼で作られています。

Heating system

横型炭化炉の加熱方式は外部バーナーや内部加熱装置など様々な使い方が可能です。

加熱システムは、炉内に高温環境を提供し、原料の炭化プロセスを促進するために使用されます。

Handling unit

炉内には、原料を配置して完成品を加工するためのハンドリングユニットがあります。ハンドリングユニットは通常、木材原料を置き、炭化後の完成した木炭を取り出すための平坦なエリアです。

Exhaust system

横型木炭炉には、炉内の空気循環を確保し、炭化プロセスをスムーズに進めるために、発生する排ガスや煤を排出する排気装置も装備されています。

横型炭化炉用マッチケージ

横型炭化炉用の適合ケージは、原料および完成した木炭製品の積み込みと取り出しが容易になるように設計されています。

このケージは、炭化プロセス中にバイオマス材料を取り扱うための便利で安全な方法として機能します。

これにより、炉への材料の投入が容易になり、炭化が完了したら効率的に木炭を除去できます。

この設計により、炭化プロセスの全体的な効率と使いやすさが向上し、炉セットアップの重要なコンポーネントとなっています。

横型炭化炉で炭化する材料

- 果物の殻: ココナッツの殻、果物の粒 などの果皮材を炭化して果皮炭を製造し、農地整備や園芸栽培に利用されます。

- 竹: さまざまな竹製品や竹自体も、竹炭を作るための一般的な炭化材料です。

- 植物残渣:各種植物廃棄物や植物残渣など 葉と花びら、環境に優しい木炭を生産するために炭化することもできます。

- ピーナッツの殻: 落花生の殻は、落花生殻炭の製造に使用できる一般的な炭化材料です。

木炭製造ラインの横型炭化炉

The horizontal carbonization furnace is a commonly used component in the wood charcoal production line. It plays a crucial role in the process of converting raw wood materials into high-quality charcoal.

In the mechanical charcoal making machine line, this carbonizing furnace is used after the biomass briquette machine.

石炭製造ラインにおいて、原料を炭化して籾殻炭、ヤシ炭、木炭、竹炭などの各種炭を製造する横型炭化炉です。

炭化炉の梱包・配送

この横型炭化器は大型のため、港への直送となります。必要に応じて、安全に輸送できるようにプラスチックフィルムで梱包します。

横型炭化炉の技術パラメータ

横型炭化炉の一般的なモデルは次の 3 つです。

- SL-1300: 炉当たりの能力は 900 ~ 1200kg、炭化時間は約 12 ~ 14 時間です。機械全体の重量は2500kg、サイズは3×1.7×2.2メートルです。炭化効率が高く、安定した性能を発揮するため、中小規模の木炭生産に適しています。

- SL-1500: この炭化能力は炉あたり 1500 ~ 2000kg で、炭化時間は約 12 ~ 14 時間です。機械全体の重量は4000kg、サイズは4.5 * 1.9 * 2.3メートルです。炭化効率が高く、中規模の木炭生産に適しており、一定の生産需要に対応できます。

- SL-1900: 炉当たりの能力は 2500 ~ 3000kg、炭化時間は約 12 ~ 14 時間です。機械全体の重量は5500kg、サイズは5×2.3×2.5メートルです。大規模な木炭生産に適しており、生産効率が高く、大量の木炭生産の需要に応えることができます。

人気商品

木製パレットブロック用おがくずブロック製造機

木材パレットブロック製造機は…のためのものです、

木材細断用工業用ハンマーミルクラッシャー

木製ハンマー粉砕機は、木の枝を粉砕するためのもので、…

練炭用熱収縮フィルム包装機

チャコールブリケットパッキング機は、実際には熱収縮します…

バーベキュー炭ボールプレス機

Shuliy 木炭ボールプレス機は、押出するための機械です…

大量木材チップ製造用の小型ディスクウッドチッパー

ディスク木材チッパーは木材をチップにするよう設計されています、…

シーシャ水タバコ炭パック用ピロー包装機

シーシャ用木炭包装機は、実際には枕包装…

丸太を切断するための製材機

木材製材機は丸太を加工するように設計されています…

ラウンド&キュービックシーシャ炭タブレットプレス機

このシーシャ炭機は効率の良さのためのものです…

BBQ用炭連続乾燥機

ブリケット乾燥機はBBQ用に使用されます…