バーベキュー用炭のブリケット製造工程の完全ガイド

目次

バーベキュー用木炭ブリケットは、その安定した燃焼、均一な熱分布、煙や臭いの最小化で広く人気があります。このガイドは、原料準備から最終梱包までの産業用バーベキュー用木炭ブリケットの製造工程全体を詳述し、この技術の包括的な理解を提供します。

原材料の準備と処理

バーベキュー用木炭の品質は、主に原料に依存します。一般的な原料には次のものがあります:

- 木片、木屑、竹の削り、米ぬか、ピーナッツ殻、ココナッツ殻粉末など。

これらの材料は不純物がなく、含水率は12%以下である必要があります。原料が湿りすぎている場合は、木屑乾燥機を使用して適切な成形を確保します。

炭化工程

バーベキュー用木炭ブリケットの製造過程では、炭化が必要であり、木材を高炭素木炭に変換します。例えば、

- 連続炭化窯: 大規模生産に適しており、24時間連続給炭と炭の出力を可能にします。

Shuliyの炭化炉は、省エネルギーの燃焼システムを採用し、排ガスを再循環させて二次燃焼を行い、エネルギー消費と粉塵排出を削減しながら、国際的な環境基準を満たしています。

粉砕と混合

炭化後、材料はホイールグラインダーミルに入り、さらに粉砕・粉末化されます。その後、正確な比率でバインダー(でんぷん、ベントナイト、タピオカ粉など)と均一に混合されます。

このステップは、バーベキュー用木炭の均一な組成と堅牢な成形を確保するために重要です。

BBQ炭ブリケットの成形

木炭粉末の製造完了後、顧客の要件に基づいて完成品のオプションを選択できます:

標準的なバーベキュー用木炭の形状(丸型、角型、枕型など)には、木炭ボールプレス機を使用して木炭ブリケットを成形します。

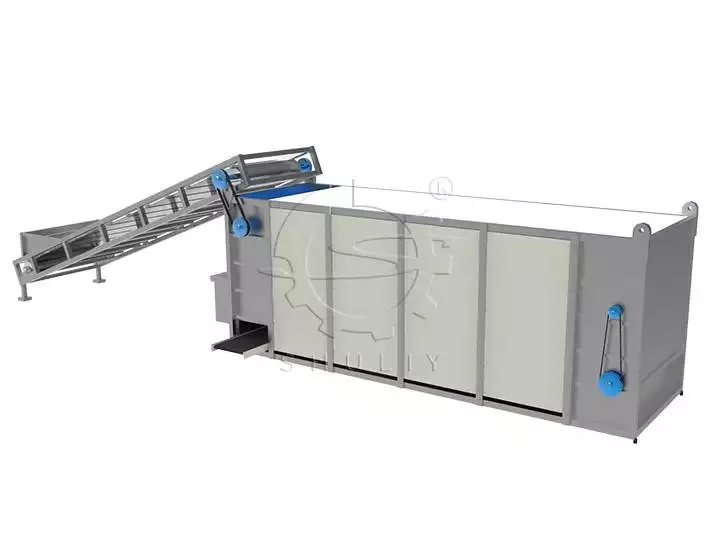

乾燥

製造後、木炭棒は一定の温度を保持し、木炭乾燥機を使用して乾燥されます。これにより、完成品の完全性と美観が保たれます。

梱包と保管

バーベキュー用木炭ブリケット製造工程の最後のステップは梱包で、通常は定量包装機を使用します。

- 梱包仕様:1kg、2kg、5kg、10kgなど。

- 梱包タイプ:クラフト紙袋、カラー印刷袋、箱入りなど。

- カスタムロゴ印刷:スーパーマーケットや輸出チャネル向けにブランド情報を印刷可能。

Shuliyは、自動計量包装機やラベリング機を提供し、カスタマイズされた包装ソリューションをサポートします。

シュリーBBQ炭製造ラインの利点

- 完全自動化された工程設計:乾燥から梱包までシームレスに移行。

- 高密度成形:木炭ボールは長時間燃焼を可能にします。

- 省エネルギーで環境に優しい:排ガス再循環システムによりエネルギー消費を削減。

- カスタマイズ可能なソリューション:原料の種類、生産量、木炭の形状に基づいた調整された構成。

- 総合的なアフターサポート:設置指導、技術研修、生涯サービスを提供。

興味があれば、カスタマイズされた木炭製造ソリューションについてお問い合わせください!