Zaagselhoutskoolproductielijn voor recycling van biomassa

Zaagselbrikettenhoutskoolvervaardigingsmachine | Houtskoolmachine

Zaagselhoutskoolproductielijn voor recycling van biomassa

Zaagselbrikettenhoutskoolvervaardigingsmachine | Houtskoolmachine

Inhoudsopgave

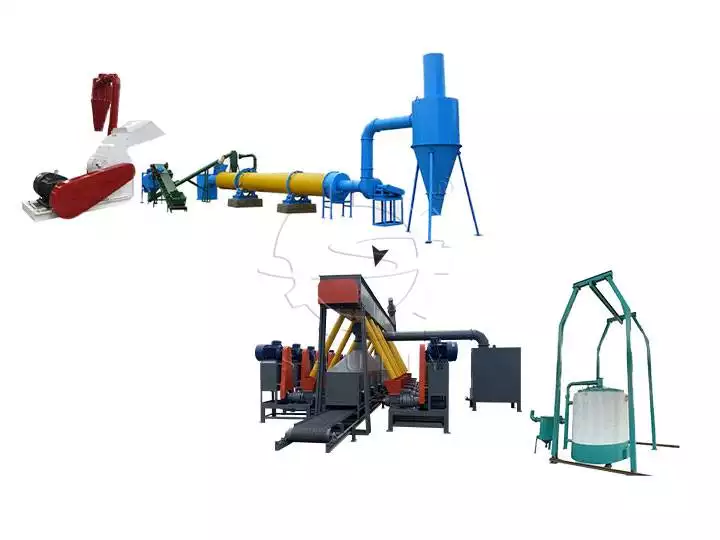

De houtsnippers-charcoal productielijn is ontworpen om houtsnippers, houtspaanders, houtkrullen, enz. om te zetten in hoogwaardige charcoal-briketten door brikettering en karbonisatie.

Deze houtskoolverwerkingsfabriek heeft capaciteiten van 1-3t/d, 3-6t/d en 6-10t/d. Machinemodellen variëren voor verschillende uitvoerconfiguraties. Wij kunnen de apparatuur flexibel configureren volgens uw wensen.

Vanwege het eerst briketteren en vervolgens carboniseren, omvatten houtskoolmachines die voor deze lijn voor het maken van zaagselhoutskool worden gebruikt, een breker, een roterende droger, een zaagselbriketmachine en een houtskooloven. Dit is een geweldige oplossing voor het recyclen van zaagsel om winst te maken.

Hoe maak je houtskool van zaagsel?

Stap 1: Het verpletteren van grondstoffen

Vanwege de verschillende maten van de resthout-ruwe materialen wordt de hamermolen toegepast om de ruwe materialen te vermalen tot kleine deeltjes (3-5mm) door de messen en hamers.

Stap 2: Zaagsel drogen

Het vochtgehalte van het geplette hout kan variëren, en er zijn vereisten voor de ruwe materialen voor het maken van houtsnippers-briketten, dus het is nodig om de houtsnippers-droger te gebruiken om het vochtgehalte te controleren op ≤ 12%.

Stap 3: Zaagsel losschroeven

Omdat er een grote hoeveelheid zaagsel in de machine terechtkomt, kan te veel zaagsel er gemakkelijk voor zorgen dat de machine verstopt raakt. Daarom is een spiraalaanvoer nodig om het zaagsel nauwkeurig te verdelen.

Stap 5: Biomassabriketten persen

De snippers zijn 3-5mm, en het vochtgehalte is ≤12%, dus de snippers worden rechtstreeks onder hoge temperatuur en hoge druk met een snippers-brikettenpers geperst tot pini kay-briketten.

Stap 6: Het carboniseren van zaagselbriketten

Na het verkrijgen van dichte en compacte houtsnippers-staven, wordt charcoal van houtsnippers-briketten geproduceerd door karbonisatie met een verticale koolsteenovens.

Stap 7: Verpakken van zaagsel-houtskoolbriketten

Omdat het uiteindelijk verkocht moet worden, kan een goede verpakking u helpen om klanten beter aan te trekken en de verkoop te vergroten. Daarom moet op dit moment de charcoal-brikettenverpakkingsmachine worden gebruikt.

Voordelen van Shuliy zaagselbrikettenhoutskoolverwerkingsfabriek

- Capaciteiten van 1-3t/d, 3-6t/d en 6-10t/d: Realiseer een gemechaniseerde werking, die de productie-efficiëntie aanzienlijk verbetert en kan voldoen aan de vraag van grootschalige productie.

- Verander afvalhout in waardevolle houtskoolbriketten: Deze lijn kan afvalhoutbronnen efficiënt benutten en afvalzaagsel omzetten in zaagsel-houtskoolbriketten om economische voordelen te creëren.

- Stabiele kwaliteit van houtskoolbriketten: Vanwege de uniforme zaagselbriketten en de stabiele carbonisatietemperatuur en -omgeving heeft de uiteindelijke zaagselbriket-houtskool een stabiele kwaliteit en een superieur brandeffect.

- Multifunctionele toepassing: Geschikt voor zaagsel, houtsnippers, houtkrullen, biomassa, rijstdoppen etc.

- Milieubescherming en energiebesparing: Energiebesparend ontwerp vermindert het energieverbruik en vermindert tegelijkertijd de uitlaatemissies, wat vriendelijk is voor het milieu.

Capaciteit van de productielijn voor zaagselhoutskool

1-3t/d productielijn voor houtskoolbriketten van zaagsel

- Geschikt voor kleinschalige houtskoolproductie en startende bedrijven.

- Houtskoolproductieproces: houtbreker → hamermolen → zaagseldroger → houtbriketpers (1 set) → verticale carbonisatiemachine → verpakkingsmachine.

- Functies: lage investering en goede lange termijn rendementen.

3-6t/d verwerkingslijn voor biomassa-houtskool

- Geschikt voor middelgrote houtskoolproductie-installaties.

- Zaagsel houtskool briket lijnconfiguratie maken: houtbreker → hamermolen → zaagseldroger → houtbrikettenpers (2 sets of meer) → verticale carbonisatieoven → verpakkingsmachine.

- Functies: Middelgrote investering met sneller rendement (vergeleken met de eerste).

6-10t/d zaagselhoutskoolproductielijn

- Geschikt voor grote houtskoolfabrieken.

- Configuratie van zaagselbriketten voor het maken van houtskoolmachines: trommelversnipperaar → hamermolen → zaagseldroger → houtbriketpers (3 sets of meer) → hijs-carbonisatiemachine → verpakkingsmachine.

- Functies: grote investering en snel rendement.

Toepassingen van houtzaagsel-houtskoolproductielijn

- Grote houtverwerkingsfabriek

- Houtskool zakelijke nieuwkomers

- Milieuvriendelijke onderneming

- Producent van biomassabrandstoffen

- Landbouwcoöperaties

- Energiebedrijf

Succesvol voorbeeld van het maken van houtskoolbriketten uit zaagsel

Shuliy-houtsnippers-charcoalmaakmachine helpt client uit Myanmar bij het maken van bamboo-charcoal-briketten

Klant uit Myanmar plant een nieuw houtskoolbedrijf, waarbij bamboe wordt omgezet in bamboe-houtskoolstokken die met winst kunnen worden verkocht.

Nadat hij het had begrepen, was hij tevreden met de configuratie, de productiecapaciteit en de after-sales service van onze machine, dus koos hij voor onze machinelijn voor het maken van zaagselbriketten voor houtskool.

Verzend charcoal-verwerkingsinstallatie naar Saoedi-Arabië om houtsnippers-charcoal te maken van houtchips

Deze Saoedische klant heeft een houtfabriek en heeft vaak veel houtsnippers en wil afval in schatten omzetten, dus startte hij een houtskoolbedrijf.

Nadat hij het productieproces van onze zaagselhoutskoolproductielijn heeft begrepen, begrijpt hij dat dit proces niet alleen volledig gebruik maakt van houtsnippers, maar ook hoogwaardige houtskoolstaven produceert, die kunnen voldoen aan de lokale marktvraag naar milieuvriendelijke brandstoffen.

Bovendien verzorgen wij ook diverse after-sales services zoals installatie, inbedrijfstelling etc., dus heeft hij onze houtskoolmachine besteld.

Hoe bestel ik een zaagsel-houtskoolproductielijn bij Shuliy?

Bent u op zoek naar een oplossing voor charcoal maken van sawdust? Neem nu contact met ons op voor meer details! Onze salesmanager ontwerpt de beste oplossing voor uw behoeften.

Het aankoopproces is als volgt:

- Neem contact met ons op om uw wensen kenbaar te maken.

- Bespreek machinedetails (zoals capaciteit, configuratie, etc.) met onze verkoopmanager.

- Leg uw twijfels uit en bepaal de machines die u wilt.

- Betaal de aanbetaling en start de productie van de machine.

- Beëindig de machineproductie en betaal het saldo.

- Boek een schip voor transport.

- Ontvang de machine en start de houtskoolhandel.

Houtspaanderbrikettenmachine voor het maken van Pini Kay-briketten

Shuliy zaagsel briketmachine (biomassa briketmachine) kan houtsnippers persen,…

Weet je de prijs van de houtstofbriquettemachine?

Wanneer u een biomassa-briketmachine koopt, moet u letten op…

SL-50 biomassa briquettextruder verkocht aan Duitsland

Onlangs heeft onze Duitse klant bij ons een biomassa-briketmachine gekocht…

Verenigde Arabische Emiraten bestelden houtsnippers-brikettenkoolmaker om winst te maken in de koolstofhandel

De klant uit de VAE heeft onlangs onze zaagselbriket houtskoolmachine gekocht…

Saudi-Arabië gebruikt houtsnippers-brikettenkoolproductielijn om kool te maken van houtchips

Goed nieuws! We exporteren met succes de productie van zaagselbriket houtskool…

Hoe begin je met houtsnippers-brikettenkool in Maleisië?

Als een land rijk aan hulpbronnen heeft Maleisië een groot aantal…

Succesvolle installatie en operatie van koolstofbriketten-productielijn uit Guinea

Onlangs heeft Shuliy Machinery met succes de installatie en inbedrijfstelling van… voltooid

Heet product

Roterende waterpijpkoolstofmachine voor ronde & kubus shisha-koolstof

De ronde hukaalskool charcoal machine is speciaal bedoeld voor…

Industriële palletvermaler te koop

Afvalhoutversnipperaar is ontworpen voor het verwerken van…

Kleine schijfhoutversnipperaar voor massale houtchipsproductie

Schijfhoutversnipperaar is ontworpen om hout te versnipperen,…

Ronde & kubieke shisha-houtskooltabletpersmachine

Deze shisha-houtskoolmachine is bedoeld voor het efficiënt…

Doorlopende houtskooloven te koop

De continue carbonisatieoven wordt speciaal gebruikt om…

Hamermolen voor het malen van houtskool en kolen

Houtskoolmaler kan verschillende soorten… vergruizen

Industriële hamermolen voor het versnipperen van hout

Houthamermolen is voor het vermalen van takken,…

Honingraatbrikettenmachine voor kolenpersing

Onze honingraatbriketmachine is gespecialiseerde apparatuur voor…

Vlakke pers voor diervoederpellets voor het maken van diervoeder

Veevoerpelletmachine is ontworpen om hoogwaardige… te produceren