Sawdust charcoal production line for biomass recycling

Sawdust Briquette Charcoal Making Machine | Charcoal Machine

Sawdust charcoal production line for biomass recycling

Sawdust Briquette Charcoal Making Machine | Charcoal Machine

Table of Contents

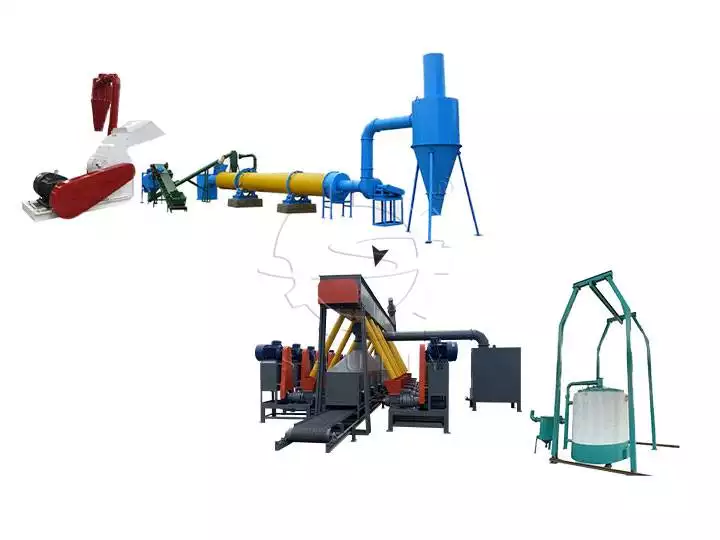

The sawdust charcoal production line is designed to convert sawdust, wood chips, wood shavings, etc. into high-quality charcoal briquettes by briquetting and carbonization.

This charcoal processing plant has capacities of 1-3t/d, 3-6t/d, and 6-10t/d. Machine models vary for different output configurations. We can flexibly configure the equipment according to your needs.

Because of adopting firstly briquetting and then carbonizing, charcoal machines used for this sawdust charcoal making line include crusher, rotary dryer, sawdust briquette machine and charcoal furnace. This is a great solution for sawdust recycling to make profits.

How to make charcoal from sawdust?

Step 1: Crushing raw materials

Because of the different sizes of the waste wood raw materials, the hammer mill is applied to pulverize the raw materials into small particles(3-5mm) through the blades and hammers.

Step 2: Drying sawdust

The humidity of the crushed wood may vary, and there are requirements for the raw materials for making sawdust briquettes, so it is necessary to use the sawdust dryer to control the humidity at ≤ 12%.

Step 3: Screw separating sawdust

Because a large amount of sawdust enters the machine, too much sawdust at one time can easily cause the machine to be blocked, thus a spiral feeder is needed to accurately distribute sawdust.

Step 5: Pressing biomass briquettes

The sawdust size is 3-5mm, and the humidity is ≤12%, so the sawdust is directly pressed into pini kay briquettes using a sawdust briquette press under high temperature and high pressure.

Step 6: Carbonizing sawdust briquettes

After obtaining dense and compact sawdust rods, the sawdust briquette charcoal is produced through carbonization using a vertical charcoal furnace.

Step 7: Packaging sawdust charcoal briquettes

Because eventually it is to be sold, good packaging can help you better attract customers and expand sales. Therefore the charcoal briquette packaging machine needs to be used at this time.

Advantages of Shuliy sawdust briquette charcoal processing plant

- Capacities of 1-3t/d, 3-6t/d and 6-10t/d: Realize mechanized operation, which greatly improves the production efficiency and can meet the demand of large-scale production.

- Turn waste wood into valuable charcoal briquettes: This line can efficiently utilize waste wood resources and convert waste sawdust into sawdust charcoal briquettes to create economic benefits.

- Stable quality of charcoal briquettes: Because of the uniform sawdust briquettes and stable carbonization temperature and environment, the final sawdust briquette charcoal has stable quality and superior burning effect.

- Multifunctional application: Suitable for sawdust, wood chips, wood shavings, biomass, rice husks, etc.

- Environmental protection and energy saving: Energy-saving design reduces energy consumption, and at the same time reduces exhaust emissions, which is friendly to the environment.

Capacity of sawdust charcoal production line

1-3t/d sawdust charcoal briquette production line

- Suitable for small-scale charcoal making and start-up businesses.

- Charocal production process: wood crusher→hammer mill→sawdust dryer→wood briquette press(1 set)→vertical carbonization machine→packing machine.

- Features: low investment and good long-term returns.

3-6t/d biomass charcoal processing line

- Suitable for medium-sized charcoal production plants.

- Sawdust charcoal briquette making line configuration: wood crusher→hammer mill→sawdust dryer→wood briquette press(2 sets or more)→vertical carbonization furnace→packaigng machine.

- Features: Medium investment with quicker returns (compared to the first one).

6-10t/d sawdust charcoal production line

- Suitable for large-sized charcoal making plants.

- Sawdust briquette charcoal making machine plant configuration: drum chipper→hammer mill→sawdust dryer→wood briquette press(3 sets or more)→hoisting carbonization machine→packaigng machine.

- Features: big investment and fast returns.

Applications of wood sawdust charcoal production line

- Large wood processing plant

- Charcoal business newcomers

- Environmentally friendly enterprise

- Biomass fuel producer

- Agricultural cooperatives

- Energy company

Successful case of making charcoal briquettes from sawdust

Shuliy sawdust charcoal making machine helps Myanmar client make bamboo charcoal briquettes

Myanmar client plans a new charcoal business, converting bamboo into bamboo charcoal sticks to sell for profit.

After understanding, he was satisfied with our machine’s configuration, production capacity and after-sales service, so he chose our sawdust briquette charcoal making machine line.

Send charcoal processing plant to Saudi Arabian to make sawdust briquette charcoal from wood chips

This Saudi customer has a wood factory and often has a lot of wood chips and wants to turn waste into treasure, so he started a charcoal business.

After understanding the production process of our sawdust charcoal production line, he understands that this process not only makes full use of wood chip resources, but also produces high-quality charcoal rods, which can meet the local market demand for environmentally friendly fuels.

Moreover, we also provide various after-sales services such as installation, commissioning, etc., so he ordered our charcoal machine.

How to order sawdust charcoal production line from Shuliy?

Are you looking for a solution for charcoal making from sawdust? If yes, contact us now to get more details! Our sales manager will design the best solution for your needs.

The purchase process is as follows:

- Contact us to state your requirements.

- Discuss machine details(like capacity, configuration, etc.) with our sales manager.

- Explain your doubts and determine the machines that you want.

- Pay the deposit and start machine production.

- Finish machine production and pay balance.

- Book a ship for transportation.

- Receive the machine and start the charcoal business.

Sawdust briquette machine for Pini Kay briquettes making

Shuliy sawdust briquette machine(biomass briquette machine) can press wood chips,…

Do you know sawdust briquette machine price?

When you buy a biomass briquetting machine, you must care…

SL-50 biomass briquette extruder machine sold to Germany

Recently, our German customer purchased from us a biomass briquette…

UAE ordered sawdust briquette charcoal making machine to profit in charcoal business

The UAE customer has recently purchased our sawdust briquette charcoal…

Saudi Arabia uses sawdust briquette charcoal production line to make charcoal from wood chips

Good news! We successfully export the sawdust briquette charcoal production…

How to start sawdust briquette charcoal in Malaysia?

Being a resource-rich country, Malaysia has a large number of…

Hot Product

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually heat shrink…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Wood sawmill machine for log cutting

Wood sawmill machine is designed to process logs…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…

Roller log debarking machine for wood bark peeling

Log debarking machine is designed to efficiently and…

Sawdust block making machine for wooden pallet blocks

The wood pallet block making machine is for…

Charcoal briquette making machine for coal plant

Charcoal briquette making machine is used to make…