特点一览

目录

The rotary dryer machine, or drum dryer is drying equipment to dry various materials such as sawdust, and rice husks, controlling the water content ranging from 10%-12%.

如果要使用这种木屑烘干机,入料粒度应≤5mm。

它始终在木炭生产线上工作,生产高质量的型煤。

转筒烘干机特点

- 高效干燥:回转烘干机可以高效快速地干燥物料,提高生产效率。

- 适用范围广:适用于各种物料,包括小颗粒、块状、粉状等不同类型的物料。

- 可靠稳定:设备结构稳定,运行可靠,减少停机时间,提高生产效率。

- 干燥均匀:物料在转筒内均匀翻滚,保证干燥过程中受热均匀。

- 布局灵活:可根据现场情况灵活布置安装,节省空间。

- 售后支持:我们提供完善的售后服务,包括维修、保养等,保证设备长期稳定运行。

出售的转筒烘干机技术数据

Model: SL-800, SL-1000, SL-1200, SL-1500

Capacity: 500kg/h, 1000kg/h, 2000kg/h, 3000kg/h

Power: 2.2+7.5kw, 3+15kw, 3+18.5kw, 5.5+22kw

Feeding diameter: ≤5mm

Applicable materials: sawdust, rice husks, sand, coal, and other small fine materials

转筒烘干机可以烘干哪些物料?

Drum dryer is suitable for drying many kinds of materials, such as sawdust, rice husks, coal powder, ore, gypsum, wood chips, wine dregs, grain, fruit peel, sand, organic chemicals and so on.

无论是湿矿石还是湿木片,回转烘干机都能高效完成烘干任务,将物料烘干至规定湿度。

回转式干燥机的应用

主要用于干燥湿物料,降低物料的湿度,提高生产效率。

This equipment is widely used in various industrial fields, such as mining, metallurgy, construction, chemical industry, etc., and can dry a variety of materials.

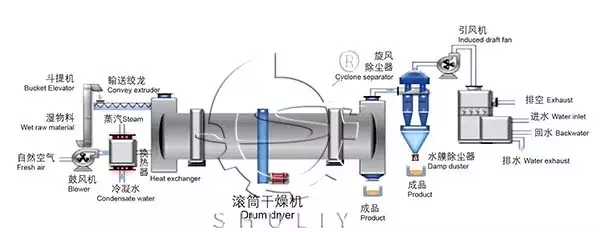

转筒烘干机的工作流程

滚筒干燥机的工作原理比较简单、高效。

步骤一:送料

物料通过给料装置进入滚筒,通常借助螺旋输送机。

第二步:热交换

物料在旋转筒体内与燃料进行热交换,产生高温热空气。

第三步:材料滚压

物料在回转筒内翻滚、翻滚,靠重力和热风的作用逐渐干燥。

第四步:排湿

干燥过程中,水分通过排气口排出,从而实现物料的快速干燥。

转筒烘干机设计

如上图所示,木屑烘干机有进料口、滚筒干燥机、出料口、除尘器等组成。

由于回转式干燥机的独特特点,该机有不同的长度。如果有兴趣,欢迎联系我们了解更多详情!

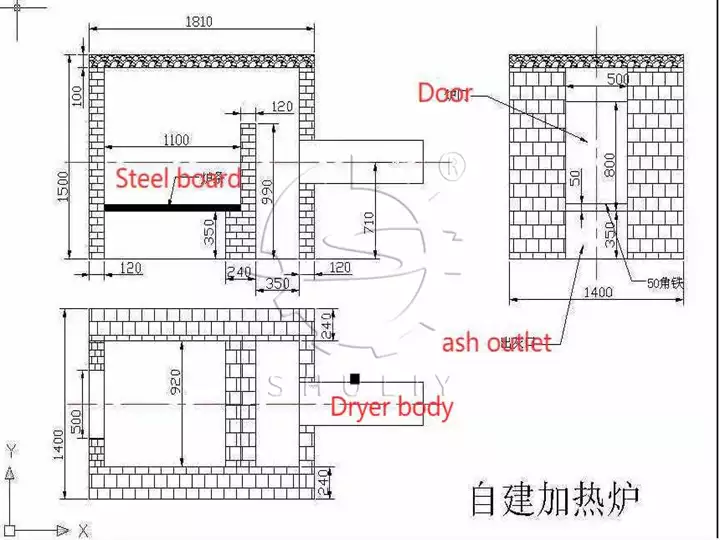

稻壳烘干机干燥燃料

该设备通常采用燃料作为能源,常用的燃料有煤炭、天然气、柴油等。

还可以自己建砖窑,烧木头,比较经济。

燃料在转筒烘干机内燃烧,产生高温热能,利用热风传导至物料,实现物料的干燥。

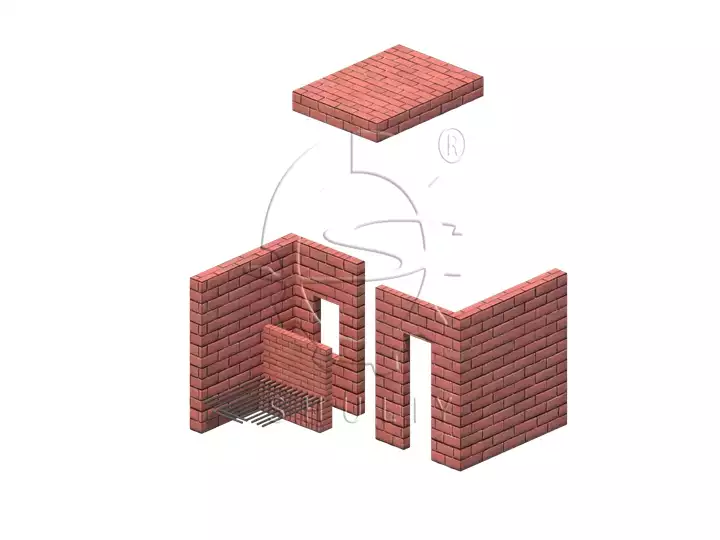

砖窑设计提供热源

木炭生产线中为什么要使用回转烘干机?

回转烘干机在各种生产线中发挥着重要的作用。在木炭生产线中,常用于生产线的前端。

Whether the charcoal is carbonized using a charcoal furnace or directly made into sawdust briquettes, the raw material requirement is 10%-12% moisture.

因此,这款烘干机可以有效帮助您大规模加工原料

转鼓木屑烘干机包装发货

If you want to make high-quality sawdust briquette or charcoal, this machine is the ideal choice for you. Contact us for more machine details!

热门产品

旋转式水烟壶炭机,用于生产圆形和立方体水烟壶炭

旋转水烟炭机专用于…

炭煤粉碎用锤式粉碎机

木炭粉碎机可以粉碎各种……

椰壳炭制造用炭机

椰子壳木炭制作机设计用于…

出售连续炭炉

连续炭化炉专用于将…转化为…

木材锯木机用于原木切割

木材锯木机用于加工原木…

滚筒剥皮机用于木材剥皮

原木去皮机旨在高效且……

烧烤木炭球压机

Shuliy炭球压制机用于压制…

平模喂料颗粒机,用于动物饲料制造

喂料颗粒机旨在生产高质量的…

液压水烟壶烟草炭压机

该水烟炭压片机可高效...