Produktionslinie für Holzkohlebriketts

Kohleverarbeitungsanlage | Holzkohlebrikettmaschine

Produktionslinie für Holzkohlebriketts

Kohleverarbeitungsanlage | Holzkohlebrikettmaschine

Funktionen auf einen Blick

Inhaltsverzeichnis

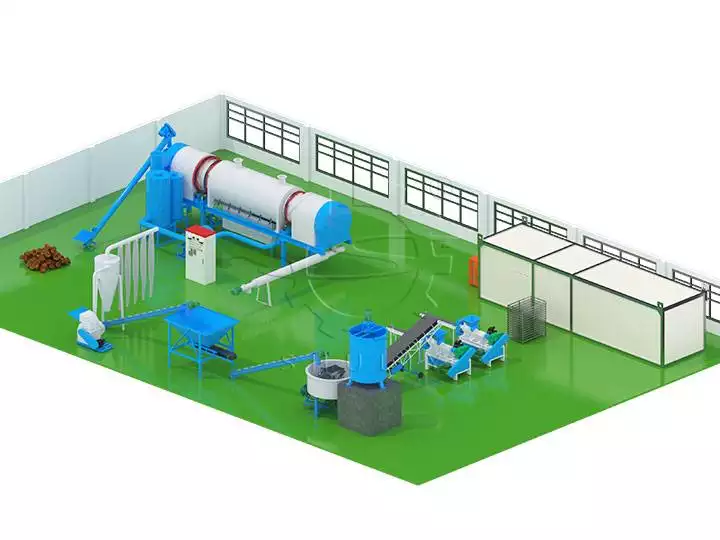

Die Holzkohlebrikett-Produktionslinie wird verwendet, um Rohstoffe wie Holzschnitzel, Sägemehl, Kokosnussschalen, Reishülsen usw. in Holzkohlebriketts mit einer Kapazität von 2 t/d, 5 t/d und 10 t/d umzuwandeln.

Der grundlegende Prozess der Holzkohleherstellung ist Karbonisierung → Holzkohlezerkleinerung → Holzkohlemahlung → Holzkohlepulver-Radmischung und -Mahlung → Holzkohlebrikett-Herstellung → Holzkohletrocknung → Holzkohlebrikett-Verpackung.

Diese Holzkohleverarbeitungsanlage verfügt über einen hohen Automatisierungsgrad, der die Effizienz der Holzkohleproduktion erheblich verbessern und den Personaleinsatz reduzieren kann. Es bietet eine effiziente Lösung für Investoren in der Holzkohleproduktion.

Prozess der Holzkohleherstellung

Schritt 1: Karbonisierung

Karbonisieren Sie das Rohmaterial im Karbonisierungsofen bei hoher Temperatur.

Wählen Sie je nach Rohstoff einen geeigneten Holzkohleofen.

- Bei Holzstämmen ist die vertikale oder horizontale Karbonisierungsmaschine gut geeignet.

- Wenn Reishülsen oder Sägemehl, das kontinuierlicher Karbonisierungsofen ist besser.

Schritt 2: Holzkohle zerkleinern

Da die Größe der im obigen Schritt verarbeiteten Holzkohle variiert, ist es notwendig, den Holzkohlebrecher zu verwenden, um die Holzkohle zu pulverisieren.

Nach dem Zerkleinern ist die Größe der Holzkohle für den nächsten Verarbeitungsschritt geeignet.

Schritt 3: Holzkohle mahlen

Die zerkleinerte Holzkohle muss erneut gemahlen werden.

Verwenden Sie die Raymond-Mühle, um die Holzkohle auf 3-5 mm zu zerkleinern, bereit für die Holzkohleformung.

Schritt 4: Mahlen und Mischen des Holzkohlepulvers

Da Holzkohlepulver keine Viskosität aufweist, nimmt es ohne Zugabe des Bindemittels keine Form an.

Daher ist es notwendig, das Bindemittel hinzuzufügen und die Radmühle-Mischmaschine zu verwenden, um vollständig zu mahlen und zu mischen. Die Funktion ist:

- Sorgen Sie dafür, dass das Holzkohlepulver vollständig und gleichmäßig vermischt wird.

- Verdichten Sie das Holzkohlepulver, um die Dichte zu erhöhen.

Schritt 5: Briketts extrudieren

Anschließend wird durch die Holzkohlebrikett-Maschine das Kohlepulver extrudiert und geformt.

Die Form des fertigen Produkts wird durch die Form bestimmt, die an die Bedürfnisse der Kunden angepasst werden kann.

Schritt 6: Trocknen der Holzkohlebriketts

Frisch geformte Briketts haben einen gewissen Feuchtigkeitsgrad, daher ist der Holzkohlebrikett-Trockner erforderlich.

Schritt 7: Briketts verpacken

Nach dem Trocknen sollten die Briketts zur Lagerung und zum einfachen Verkauf verpackt werden.

Bei diesem Vorgang wird eine Schrumpffolien-Verpackungsmaschine benötigt.

Highlights der Holzkohlebrikett-Produktionslinie

- Kapazität von 2 t/Tag, 5 t/Tag und 10 t/Tag. Unsere Holzkohleproduktionslinie kann 2 t, 5 t oder 10 t Holzkohle pro Tag herstellen, was sehr effizient ist und den Bedarf der kleinen, mittleren oder großen Holzkohleproduktion decken kann.

- Herstellung von sechseckigen oder quadratischen Holzkohlebriketts. Die Form des fertigen Produkts wird durch die Form bestimmt. Wir verfügen über eine Vielzahl von Formen, mit denen Holzkohleprodukte in verschiedenen Formen hergestellt werden können, z. B. sechseckig, quadratisch, sternförmig usw.

- Flexible Anpassung. Je nach Bedarf und Budget des Kunden können wir eine flexible Anpassung der Holzkohlemaschinenlinie vornehmen.

- Installationsservice vor Ort. Sobald die Ausrüstung am Standort eintrifft, können wir Ingenieure beauftragen, die Produktionslinie vor Ort zu installieren.

Verfügbare Kapazitäten von Produktionslinien für Holzkohlebriketts zum Verkauf

Marke: Shuliy

Kapazität: 2 t/Tag, 5 t/Tag, 10 t/Tag

Konfiguration: Karbonisierungsofen, Holzkohlebrecher, Raymond-Mühle, Radmischer-Mühle, Holzkohlebrikett-Maschine, Holzkohlebrikett-Trockner und Verpackungsmaschine

Garantiezeit: 1 Jahr

Warum die Produktionslinie für Holzkohlebriketts nutzen?

- Vielfältige Anwendungsmöglichkeiten für Holzkohlebriketts. Mit dieser Maschinenlinie zur Holzkohleherstellung können hochwertige Kohlebriketts hergestellt werden, die in vielen Bereichen wie Grillen, Heizen, Heizkesseln usw. weit verbreitet sind.

- Tolle Lösung für Holzkohlehersteller. Die hervorragende Qualität der Endprodukte und die effiziente Produktionskapazität machen die Produktionslinie für Holzkohlebriketts zur bevorzugten Ausrüstung für viele Hersteller von Holzkohlekugeln.

- Verwandeln Sie Abfall in Schätze. Diese Produktionslinie für Holzkohlebriketts wird aus Abfallmaterialien wie Holz, Kokosnussschalen, Reisschalen usw. hergestellt. Es hilft dabei, Abfälle zu recyceln und wiederzuverwenden und so Gewinne zu erzielen.

Erfolgreiche Fälle einer Holzkohleproduktionslinie

Unsere Holzkohleverarbeitungsanlage in Kenia in Betrieb

Unser kenianischer Kunde kaufte unsere Produktionslinie für Holzkohlebriketts, um Kohlebriketts für den Verkauf vor Ort herzustellen.

Nachdem er die Maschine erhalten und verwendet hatte, hatte dieser Kunde das Gefühl, dass die Maschine sehr gut funktionierte, und schickte daher ein Feedback-Video.

Tipps zur Auswahl einer geeigneten Holzkohleverarbeitungsanlage

Wenn Sie eine geeignete Holzkohlebrikett-Produktionslinie kaufen möchten, können Sie bei der Auswahl der Ausrüstung die folgenden Punkte beachten.

- Qualität und Leistung der Ausrüstung

- Kapazität und Effizienz

- Energieverbrauch und Umweltschutz

- Preis und Kostenleistung

- Kundendienst und technischer Support

- Einfache Installation und Bedienung

- Ersatzteilversorgung und Wartungskosten

- Ruf und Glaubwürdigkeit des Herstellers

Nehmen Sie jetzt Kontakt mit uns auf!

Sind Sie auf der Suche nach Lösungen für die Herstellung von Holzkohlebriketts? Wenn ja, kontaktieren Sie uns jetzt, unsere Holzkohleverarbeitungsanlage wird Ihnen helfen, Ihr Ziel zu erreichen.

Holzkohlebrikettmaschine für Kohlekraftwerk

Die Maschine zur Herstellung von Holzkohlebriketts dient zur Produktion geformter Holzkohle…

Chargen-Trocknungsmaschine für Briketts, Waben-Kohle, Wasserpfeifenkohle

Die Shuliy-Holzkohletrocknungsmaschine ist eine Trocknungsanlage, die schnell… trocknet.

Wärmeschrumpffolienverpackungsmaschine für Kohlebriketts

Die Verpackungsmaschine für Holzkohlebriketts ist eigentlich eine Heißschrumpffolienmaschine…

500kg/h Holzkohlebrikettmaschine zum Verkauf nach Brasilien

Glückwunsch! Unser brasilianischer Kunde hat 2 Sets Holzkohlebrikettherstellungsanlagen… bestellt!

Export SL-140 Holzkohlebrikettpresse nach Kenia

Vor Kurzem bestellte ein Kunde aus Kenia eine SL-140-Holzkohlebrikette…

1-3t/d Biomasse-Holzkohle Produktionslinie nach Myanmar verkauft

Eilmeldung an Shuliy! Ein Kunde aus Myanmar hat eine… gekauft.

Holzkohlebrikettmacher wandelt überschüssige Kohle in Guatemala um

In Guatemala suchte ein örtlicher Unternehmer nach einer innovativen Möglichkeit…

Export der Holztrocknungsmaschine nach Libyen

Kürzlich hat einer unserer Kunden in Libyen die Holzkohle gekauft…

Senegalischer Kunde wählte Shuliy-Holzkohleextrudermaschine für Expansion

Im Senegal suchte ein zukunftsorientierter Kunde nach einer Holzkohle…

20 Sets von Holzkohlebrikett-Extrudermaschinen nach Indonesien geschickt

Im Jahr 2023 wurden 20 Sets Shuliy-Holzkohlebrikett-Extrudermaschinen…

Heißes Produkt

Industrielle Palettenzerkleinerungsmaschine zum Verkauf

Die Maschine zur Zerkleinerung von Abfallholz ist zum Verarbeiten von …

Chargen-Trocknungsmaschine für Briketts, Waben-Kohle, Wasserpfeifenkohle

Diese Holzkohletrocknungsmaschine wird verwendet, um…

Flachdüsen-Futterpelletmaschine für die Tierfutterherstellung

Futtermittel-Pelletmaschine ist darauf ausgelegt, hochwertige…

Radmühle für die Mahlung und das Mischen von Kohlepulver

Kohlepulver-Mischer wird zum Mischen und…

Trommel-Holzspaltermaschine für Chipsproduktion

Die Trommel-Holzhackmaschine ist zum Zerkleinern von Holz… konstruiert

Rundmill für die Mahlung von Kohlenpulver

Die Raymond-Mühle dient zum Zerkleinern und Mahlen von Holzkohle...

Holzkohlebrikettmaschine für Kohlekraftwerk

Die Holzkohlebrikettiermaschine wird verwendet, um…

Holzkohleballpressmaschine für Barbecue

Shuliy-Kohleballenpresse ist zum Pressen…

Industrielle Hammermühle zum Zerkleinern von Holz

Holzhackmühle dient zum Zerkleinern von Holzästen,…