Charcoal briquette production line

Charcoal Processing Plant | Charcoal Briquette Machine

Charcoal briquette production line

Charcoal Processing Plant | Charcoal Briquette Machine

Features at a Glance

Table of Contents

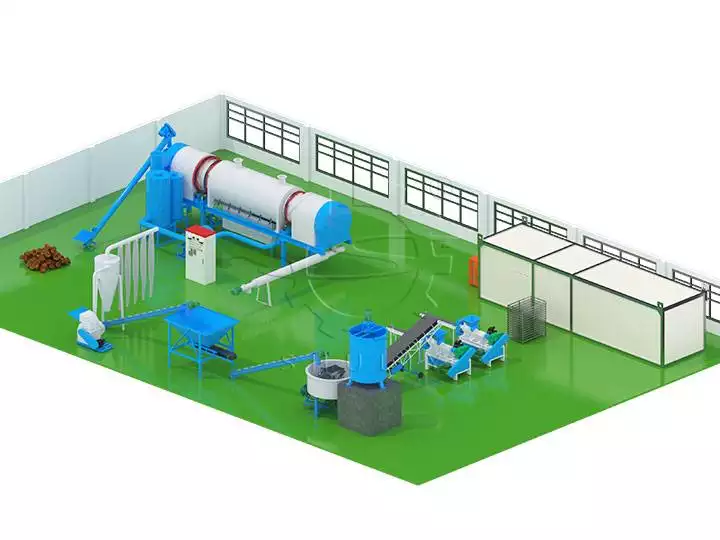

Charcoal briquette production line is used to convert raw materials such as wood chips, sawdust, coconut shells, rice husks, etc. into charcoal briquettes with a capacity of 2t/d, 5t/d and 10t/d.

The basic charcoal making process is carbonizing→charcoal crushing→charcoal grinding→charcoal powder wheel mixing and grinding→charcoal briquette making→charcoal drying→charcoal briquette packing.

This charcoal processing plant has a high degree of automation, which can greatly improve the charcoal production efficiency and reduce the input of human resources. It provides an efficient solution for charcoal production investors.

Charcoal making process

Step 1: carbonization

Carbonize the raw material using the carbonization furnace at high temperature.

Choose a suitable charcoal furnace according to the raw materials.

- If wood logs, the vertical or horizontal carbonizer machine is good.

- If rice husks or sawdust, the continuous carbonizing furnace is better.

Step 2: charcoal crushing

Because the size of the charcoal processed in the above varies, it is necessary to use the charcoal crusher to pulverize the charcoal.

After crushing, the charcoal size is suitable for the next step of processing.

Step 3: charcoal grinding

The crushed charcoal needs to be ground again.

Use the Raymond mill to crush the charcoal to 3-5mm, ready for charcoal molding.

Step 4: charcoal powder grinding & mixing

Because charcoal powder has no viscosity, it will not take shape without adding the binder.

Therefore, it is necessary to add the binder and use the wheel mill grinder to fully grind and mix. The role is:

- Make the charcoal powder fully mixed evenly.

- Compact the charcoal powder to increase the density.

Step 5: extruding briquettes

Then, through the charcoal briquette machine, the carbon powder is extruded and shaped.

The shape of the finished product is determined by the mold, which can be customized according to the needs of customers.

Step 6: charcoal briquette drying

Freshly molded briquettes have a certain degree of humidity, so the charcoal briquettes dryer is required.

Step 7: briquettes packing

After drying, the briquettes should be packaged for storage and easy sale.

In this process, a heat shrink film packaging machine is needed.

Highlights of the charcoal briquette production line

- Capacity of 2t/d, 5t/d and 10t/d. Our charcoal production line can make 2t, 5t or 10t charcoal per day, which is highly efficient and can meet the needs of small, medium or large-scale charcoal production.

- Hexagonal or square charcoal briquettes making. The shape of the finished product is determined by the mold. We have a variety of molds that can make charcoal products in various shapes, such as hexagonal, square, star-shaped, etc.

- Flexible matching. According to the customer’s demand and budget, we can make flexible matching for the charcoal machine line.

- On-site installation service. Upon the equipment arrives at the site, we can arrange engineers to install the production line on-site.

Available capacities of charcoal briquette production lines for sale

Brand: Shuliy

Capacity: 2t/day, 5t/day, 10t/day

Configuration: carbonization furnace, charcoal crusher, Raymond mill, wheel mixer grinder, charcoal briquette machine, charcoal briquette dryer and packaging machine

Warranty period: 1 year

Why use the charcoal briquette production line?

- Wide applications of charcoal briquettes. This charcoal making machine line can produce high-quality coal briquettes products, which are widely used in many fields such as barbecue, heating, boiler and so on.

- Geat solution for charcoal manufacturers. Its excellent quality of finished products and efficient production capacity make the charcoal briquettes production line the preferred equipment for many charcoal ball manufacturers.

- Turn waste into treasure. This charcoal briquette production line is made from waste materials such as wood, coconut shells, rice husks, and so on. It helps waste be recycled and reused, making profits.

Successful cases of charcoal production line

Running our charcoal processing plant in Kenya

Our Kenyan customer bought our charcoal briquette production line to produce coal briquettes for sale locally.

After receiving the machine and using it, this customer felt that the machine worked very well, so he sent a feedback video.

Tips on choosing a suitable charcoal processing plant

When you want to make a suitable charcoal briquette production line purchase, you can refer to the following points to choose the equipment.

- Equipment quality and performance

- Capacity and efficiency

- Energy consumption and environmental protection

- Price and cost performance

- After-sales service and technical support

- Easy installation and operation

- Parts supply and maintenance cost

- Manufacturer’s reputation and credibility

Get in touch with us now!

Are you looking for solutions on how to carry out the production of charcoal briquettes? If yes, contact us now, our charcoal processing plant will help you realize your goal.

Charcoal briquette making machine for coal plant

Charcoal briquette making machine is used to make shaped charcoal…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

Shuliy charcoal dryer machine is drying equipment that quickly dries…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually a heat shrink film…

500kg/h charcoal briquettes machine for sale to Brazil

Congratulations! Our Brazilian client ordered 2 sets of charcoal briquettes…

Export SL-140 charcoal briquette press machine to Kenya

Recently, a customer from Kenya ordered an SL-140 charcoal briquette…

1-3t/d biomass charcoal production line sold to Myanmar

Breaking news to Shuliy! One client from Myanmar bought a…

Charcoal briquette maker converts surplus coal in Guatemala

In Guatemala, a local entrepreneur looking for an innovative way…

Export of charcoal drying machine to Libya

Recently, one of our customers in Libya purchased the charcoal…

Senegal client chose Shuliy charcoal extruder machine for expansion

In Senegal, a forward-thinking customer was looking for a charcoal…

20 sets of charcoal briquette extruder machines sent to Indonesia

In 2023, 20 sets of Shuliy charcoal briquette extruder machines…

Hot Product

Wood shaving machine for horse, chicken bedding

Wood shavings machine is designed to produce uniform…

Charcoal briquette making machine for coal plant

Charcoal briquette making machine is used to make…

Sawdust briquette machine for Pini Kay briquettes making

Sawdust briquette machine is to press wood chips,…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

This charcoal dryer machine is used to dry…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually heat shrink…

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…

Industrial pallet crushing machine for sale

Waste wood crusher machine is designed for processing…