Productielijn voor houtskoolbriketten

Houtskoolverwerkingsfabriek | Houtskoolbrikettenmachine

Productielijn voor houtskoolbriketten

Houtskoolverwerkingsfabriek | Houtskoolbrikettenmachine

Kenmerken in één oogopslag

Inhoudsopgave

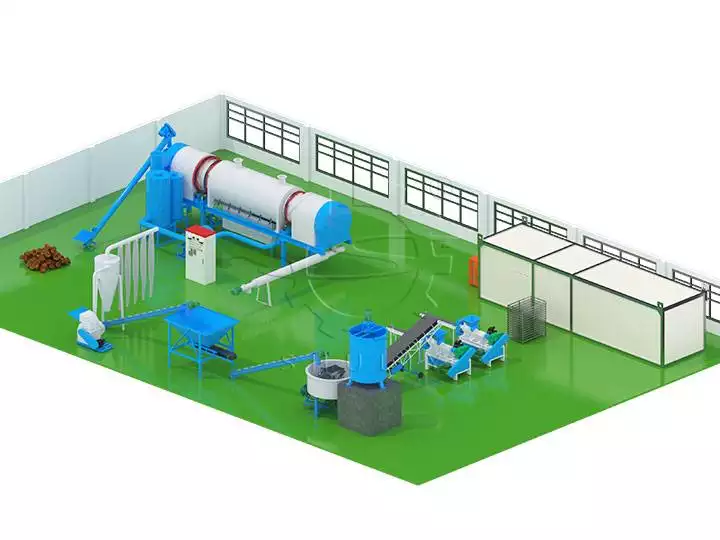

Charcoal briquette production line is used to convert raw materials such as wood chips, sawdust, coconut shells, rice husks, etc. into charcoal briquettes with a capacity of 2t/d, 5t/d and 10t/d.

The basic charcoal making process is carbonizing→charcoal crushing→charcoal grinding→charcoal powder wheel mixing and grinding→charcoal briquette making→charcoal drying→charcoal briquette packing.

Deze houtskoolverwerkingsfabriek heeft een hoge mate van automatisering, wat de efficiëntie van de houtskoolproductie aanzienlijk kan verbeteren en de inzet van menselijke hulpbronnen kan verminderen. Het biedt een efficiënte oplossing voor investeerders in de houtskoolproductie.

Proces voor het maken van houtskool

Stap 1: carbonisatie

Carboniseer de grondstof met behulp van de carbonisatieoven op hoge temperatuur.

Kies een geschikte houtskooloven op basis van de grondstoffen.

- Als houtblokken worden gebruikt, is de verticale of horizontale carboniseermachine goed.

- Als rijstdoppen of zaagsel aanwezig zijn, kan de continue carbonisatieoven is beter.

Stap 2: houtskool vermalen

Because the size of the charcoal processed in the above varies, it is necessary to use the charcoal crusher to pulverize the charcoal.

Na het pletten is het houtskoolformaat geschikt voor de volgende verwerkingsstap.

Stap 3: houtskool malen

De gemalen houtskool moet opnieuw worden gemalen.

Use the Raymond mill to crush the charcoal to 3-5mm, ready for charcoal molding.

Stap 4: houtskoolpoeder malen en mengen

Omdat houtskoolpoeder geen viscositeit heeft, zal het geen vorm aannemen zonder toevoeging van het bindmiddel.

Therefore, it is necessary to add the binder and use the wheel mill grinder to fully grind and mix. The role is:

- Zorg ervoor dat het houtskoolpoeder volledig gelijkmatig gemengd is.

- Compacteer het houtskoolpoeder om de dichtheid te vergroten.

Stap 5: briketten extruderen

Then, through the charcoal briquette machine, the carbon powder is extruded and shaped.

De vorm van het eindproduct wordt bepaald door de mal, die kan worden aangepast aan de behoeften van klanten.

Stap 6: drogen van houtskoolbriketten

Freshly molded briquettes have a certain degree of humidity, so the charcoal briquettes dryer is required.

Stap 7: briketten verpakken

Na het drogen moeten de briketten worden verpakt voor opslag en gemakkelijke verkoop.

In this process, a heat shrink film packaging machine is needed.

Hoogtepunten van de productielijn voor houtskoolbriketten

- Capaciteit van 2t/d, 5t/d en 10t/d. Onze houtskoolproductielijn kan 2 ton, 5 ton of 10 ton houtskool per dag maken, wat zeer efficiënt is en kan voldoen aan de behoeften van kleine, middelgrote of grootschalige houtskoolproductie.

- Zeshoekige of vierkante houtskoolbriketten maken. De vorm van het eindproduct wordt bepaald door de mal. We hebben verschillende mallen waarmee houtskoolproducten in verschillende vormen kunnen worden gemaakt, zoals zeshoekig, vierkant, stervormig, enz.

- Flexibele matching. Afhankelijk van de vraag en het budget van de klant kunnen we een flexibele afstemming maken op de houtskoolmachinelijn.

- Installatieservice op locatie. Zodra de apparatuur op de locatie arriveert, kunnen we monteurs regelen om de productielijn ter plaatse te installeren.

Beschikbare capaciteit van productielijnen voor houtskoolbriketten te koop

Brand: Shuliy

Capacity: 2t/day, 5t/day, 10t/day

Configuration: carbonization furnace, charcoal crusher, Raymond mill, wheel mixer grinder, charcoal briquette machine, charcoal briquette dryer and packaging machine

Warranty period: 1 year

Waarom de productielijn voor houtskoolbriketten gebruiken?

- Brede toepassingen van houtskoolbriketten. Deze machinelijn voor het maken van houtskool kan hoogwaardige steenkoolbrikettenproducten produceren, die op grote schaal worden gebruikt op veel gebieden, zoals barbecue, verwarming, ketel enzovoort.

- Geweldige oplossing voor houtskoolfabrikanten. De uitstekende kwaliteit van de eindproducten en de efficiënte productiecapaciteit maken de productielijn voor houtskoolbriketten tot de favoriete uitrusting van veel fabrikanten van houtskoolballen.

- Verander afval in schatten. Deze productielijn voor houtskoolbriketten is gemaakt van afvalmaterialen zoals hout, kokosnootschalen, rijstschillen, enzovoort. Het helpt afval te recyclen en hergebruiken, waardoor winst wordt gemaakt.

Succesvolle gevallen van houtskoolproductielijn

Onze koolverwerkingsfabriek in Kenya in bedrijf

Onze Keniaanse klant kocht onze productielijn voor houtskoolbriketten om steenkoolbriketten te produceren voor lokale verkoop.

Nadat hij de machine had ontvangen en in gebruik had genomen, vond deze klant dat de machine heel goed werkte, daarom stuurde hij een feedbackvideo.

Tips voor het kiezen van een geschikt houtskoolverwerkingsbedrijf

Wanneer u een geschikte productielijn voor houtskoolbriketten wilt aanschaffen, kunt u de volgende punten raadplegen om de apparatuur te kiezen.

- Kwaliteit en prestaties van apparatuur

- Capaciteit en efficiëntie

- Energieverbruik en milieubescherming

- Prijs- en kostenprestaties

- After-sales service en technische ondersteuning

- Eenvoudige installatie en bediening

- Leverings- en onderhoudskosten van onderdelen

- De reputatie en geloofwaardigheid van de fabrikant

Neem nu contact met ons op!

Zoekt u naar oplossingen voor de productie van charcoal briquettes? Zo ja, neem nu contact met ons op, onze koolverwerkingsinstallatie zal u helpen uw doel te realiseren.

Houtskoolbrikettenmachine voor kolenfabriek

De houtskoolbriketmaakmachine wordt gebruikt om gevormde houtskool…

Batch-type droger voor briketten, honingraatkolen, waterpijp-houtskool

Shuliy houtskooldroogmachine is droogapparatuur die snel…

Warmtekrimpfilmverpakkingsmachine voor houtskoolbriketten

De verpakkingsmachine voor houtskoolbriketten is eigenlijk een krimpfolie…

Verkoop van 500kg/u houtskoolbrikettenmachine aan Brazilië

Gefeliciteerd! Onze Braziliaanse klant bestelde 2 sets houtskoolbriketten…

Export van SL-140 houtskoolbrikettenpers naar Kenia

Onlangs bestelde een klant uit Kenia een SL-140 houtskoolbriket…

Verkochte biomassahoutskoolproductielijn van 1-3t/d aan Myanmar

Doorbraaknieuws voor Shuliy! Een klant uit Myanmar kocht een…

Houtskoolbrikettenmaker zet overtollige kolen om in Guatemala

In Guatemala zocht een lokale ondernemer naar een innovatieve manier…

Export van houtskooldroogmachine naar Libië

Onlangs kocht een van onze klanten in Libië de houtskool…

Senegalese klant koos voor Shuliy houtskoolextrusiemachine voor uitbreiding

In Senegal zocht een vooruitstrevende klant een houtskool…

20 sets van extrusie machines voor houtskoolbriketten gestuurd naar Indonesië

In 2023 werden er 20 sets Shuliy houtskoolbriketextrudermachines...

Heet product

Trommelhoutversnipperaar voor productie van houtspaanders

Trommelhoutversnipperaar is ontworpen om hout te versnipperen…

Ronde & kubieke shisha-houtskooltabletpersmachine

Deze shisha-houtskoolmachine is bedoeld voor het efficiënt…

Houtskoolbrikettenmachine voor kolenfabriek

De houtskoolbriquettemachine wordt gebruikt om…

Kussenverpakkingsmachine voor shisha-hookah houtskoolverpakking

De shisha-houtskool verpakkingsmachine, eigenlijk kussenverpakking…

Verticale houtschilfermachine voor het verwijderen van schors van bomen

De houtontschiller is ontworpen om de…

Kwantitatieve BBQ houtskoolverpakkingsmachine

BBQ-houtskool verpakkingsmachine wordt gebruikt om… te verpakken

Industriële hamermolen voor het versnipperen van hout

Houthamermolen is voor het vermalen van takken,…

Roterende waterpijpkoolstofmachine voor ronde & kubus shisha-koolstof

De ronde hukaalskool charcoal machine is speciaal bedoeld voor…

Barbecue houtskoolbalpersmachine

De Shuliy houtskoolballenpers is bedoeld voor het persen…