Làm thế nào để bạn làm gạch mùn cưa?

Mục lục

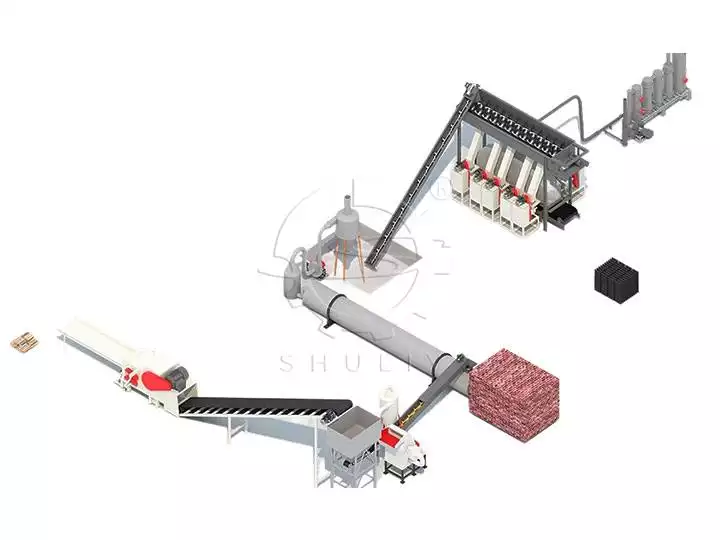

Việc làm gạch mùn cưa là một cách hiệu quả để tận dụng gỗ vụn, giúp giảm ô nhiễm môi trường và cung cấp năng lượng tái tạo. Thông qua việc sử dụng máy làm viên nén mùn cưa, mùn cưa hoặc dăm gỗ có thể được ép thành các viên gạch chắc chắn để sưởi ấm và các ứng dụng công nghiệp khác. Quy trình sản xuất của nó như sau:

1. Chuẩn bị nguyên liệu

Đầu tiên, cần chuẩn bị mùn cưa khô hoặc dăm gỗ làm nguyên liệu. Những mảnh gỗ này có thể là rác thải từ các cửa hàng mộc hoặc nhà máy chế biến gỗ.

2. Nghiền vụn gỗ

Cho dăm gỗ nguyên liệu vào máy nghiền búa gỗ để nghiền thành các hạt mịn cho quá trình xử lý tiếp theo. Kích thước sản phẩm cuối cùng nên là 3-5mm.

3. Mùn cưa khô hoặc dăm gỗ

Vì việc làm gạch mùn cưa đòi hỏi độ ẩm phải ở mức ≤12%, nên chúng ta phải sử dụng máy sấy trục quay để kiểm soát độ ẩm của nguyên liệu ở mức 12% hoặc thấp hơn.

4. Làm gạch mùn cưa

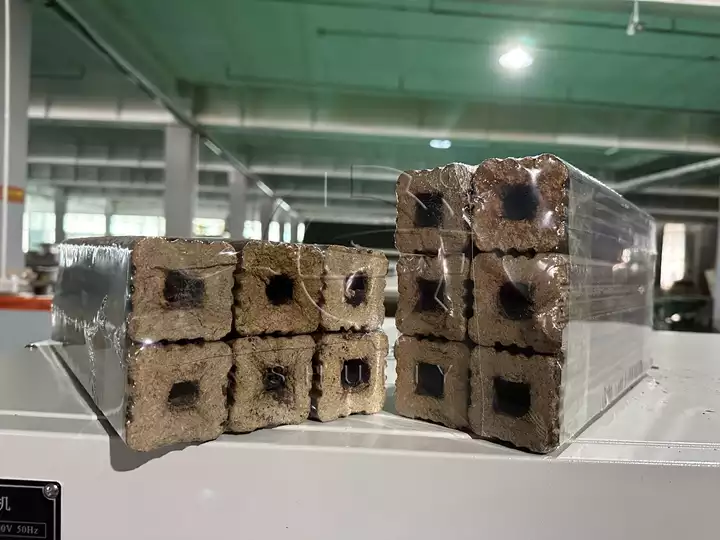

Nguyên liệu đã chuẩn bị được cho vào máy làm gạch mùn cưa. Máy làm thanh mùn cưa sẽ ép gỗ vụn thành gạch với hình dạng và kích thước nhất định bằng phương pháp đùn ép nhiệt độ cao.

5. Đóng gói và bảo quản

Sau khi sản xuất hoàn tất, các thanh sinh khối được làm khô và sẵn sàng để đóng gói và lưu trữ. Các khối này có thể được đóng gói vào túi bằng máy đóng gói co màng để dễ dàng vận chuyển và lưu trữ.

Nếu bạn quan tâm đến việc làm gạch sinh khối mùn cưa, vui lòng liên hệ với chúng tôi để biết thêm chi tiết về máy móc và giá cả!