Máy nghiền búa công nghiệp để băm gỗ

Máy nghiền búa Mill | Máy nghiền búa sinh khối

Các tính năng trong nháy mắt

Mục lục

Máy nghiền búa gỗ là một máy mạnh mẽ và đa năng để nghiền các nhánh gỗ, khúc gỗ, vỏ dừa, rơm, v.v. thành các hạt nhỏ, với công suất từ 500-3000kg/h. Máy này thường có mặt trong dây chuyền sản xuất than.

Nó được trang bị búa để đóng búa và nghiền thành bột gỗ để tạo ra mùn cưa hoặc dăm gỗ mịn.

Máy nghiền búa này được sử dụng rộng rãi trong các ngành chế biến gỗ như sản xuất viên gỗ và đóng bánh sinh khối.

Hiệu quả cao và thiết kế nhỏ gọn làm cho nó trở thành một công cụ quan trọng để biến chất thải gỗ thành tài nguyên có giá trị.

Máy nghiền búa gỗ là một giải pháp chế biến gỗ tiết kiệm chi phí với những ưu điểm vượt trội trong việc tái chế và tái sử dụng nguyên liệu gỗ.

Ưu điểm của máy nghiền búa gỗ để bán

- Đa chức năng: Máy nghiền búa sinh khối có thể xử lý nhiều loại nguyên liệu thô, bao gồm dăm gỗ, mùn cưa, rơm rạ và chất thải nông nghiệp.

- Có hiệu quả: Với động cơ mạnh mẽ và búa sắc bén, máy nghiền búa có thể nghiền vật liệu gỗ thành hạt mịn một cách nhanh chóng và hiệu quả.

- Thiết kế nhỏ gọn: Thiết kế nhỏ gọn và tiết kiệm không gian giúp nó phù hợp cho cả hoạt động nhỏ và lớn.

- Xây dựng bền vững: Máy mài búa được làm bằng vật liệu chắc chắn, có thể chịu được cường độ sử dụng cao, đảm bảo hiệu suất lâu dài.

- Giải pháp tiết kiệm chi phí: Đầu tư vào một máy nghiền búa gỗ để bán mang lại một cách tiết kiệm chi phí để xử lý nguyên liệu gỗ, tạo ra nguồn tài nguyên quý giá và giảm chất thải.

Dữ liệu kỹ thuật của máy nghiền búa cho sinh khối

| Người mẫu | Công suất (KW) | Công suất (kg / giờ) | Búa (chiếc) |

| SL-500 | 22 | 500-600 | 32 |

| SL-600 | 30 | 800-1000 | 40 |

| SL-800 | 55 | 1500-2000 | 50 |

| SL-1000 | 75 | 2000-2500 | 75 |

| SL-1300 | 110 | 2500-3000 | 75 |

Nguyên liệu của máy nghiền búa gỗ

Nguyên liệu thô cho máy hủy tài liệu búa rất đa dạng, bao gồm các sản phẩm gỗ khác nhau, dăm gỗ sau khi nghiền thô, vỏ dừa, gỗ vụn chế biến và các phế liệu gỗ khác có năng suất sản xuất cao.

Do hiệu quả và khả năng thích ứng cao, máy nghiền búa gỗ có thể xử lý một số lượng lớn các loại chất thải gỗ khác nhau và xử lý chúng thành dăm gỗ hoặc bột viên mịn, góp phần quan trọng vào việc tái sử dụng và tái chế tài nguyên.

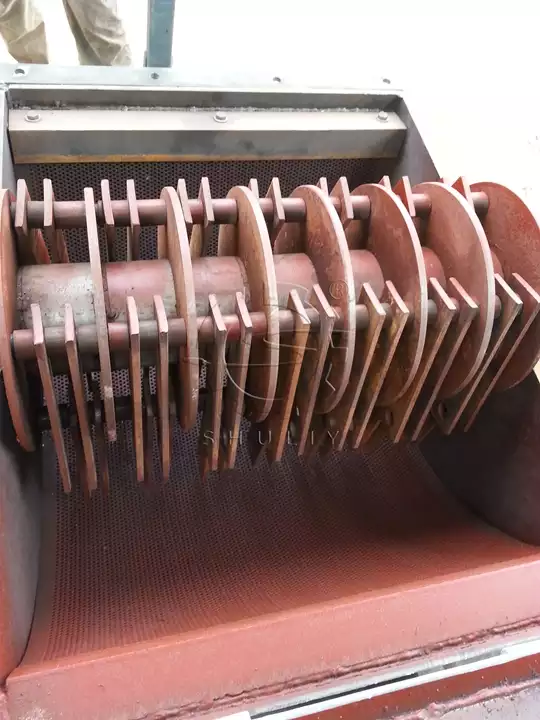

Cấu tạo của máy nghiền búa gỗ

Cấu trúc bên trong của máy nghiền búa gỗ bao gồm một số bộ phận cơ bản.

| Có/không | Tên bộ phận máy chính | Chức năng |

| 1 | Búa | Búa là bộ phận làm việc chính của máy nghiền búa. Chúng được gắn vào rôto và được điều khiển bởi động cơ. Những chiếc búa dao động và tác động vào vật liệu gỗ, làm vỡ nó thành những mảnh nhỏ. |

| 2 | Cánh quạt | Rôto là một bộ phận hình trụ có tác dụng giữ và quay búa. Nó đóng một vai trò quan trọng trong quá trình mài và đảm bảo búa hoạt động hiệu quả. |

| 3 | Màn hình | Màn hình là một tấm kim loại đục lỗ hoặc lưới nằm ở đáy buồng nghiền. Nó kiểm soát kích thước của các hạt gỗ cuối cùng. Các hạt nhỏ hơn đi qua màn hình trong khi các hạt lớn hơn tiếp tục được xử lý. |

Làm thế nào để chọn một máy nghiền búa gỗ phù hợp?

Để chọn được máy nghiền búa gỗ phù hợp cần xem xét các yếu tố sau:

- Công suất: Đảm bảo máy có thể xử lý được đầu ra mà bạn cần.

- Nguyên liệu thô: Kiểm tra xem nó có thể xử lý được loại chất thải gỗ mà bạn có hay không.

- Kích thước hạt: Xác minh rằng máy nghiền có khả năng đạt được kích thước hạt mong muốn của gỗ.

- Công suất và hiệu quả: Chọn dòng máy có công suất phù hợp và hiệu suất nghiền cao.

- Chi phí: So sánh giá cả và chọn một phương án tiết kiệm chi phí trong phạm vi ngân sách của bạn.

- Danh tiếng thương hiệu: Hãy chọn thương hiệu uy tín, được khách hàng đánh giá tốt.

- Dịch vụ sau bán hàng: Kiểm tra xem nhà cung cấp có hỗ trợ khách hàng tốt hay không.

Làm thế nào để sử dụng máy nghiền búa sinh khối?

Hãy làm theo các bước dưới đây để sử dụng máy nghiền búa gỗ một cách an toàn:

Đảm bảo an toàn

Mang thiết bị bảo hộ thích hợp và giữ khoảng cách an toàn với người ngoài cuộc.

Bật máy

Kết nối máy với nguồn điện và bật nó lên.

Cho ăn

Đổ đều nguyên liệu sinh khối vào phễu cấp liệu.

Điều chỉnh thông số

Đặt các thông số nghiền mong muốn như tốc độ, kích thước, v.v.

Giám sát hoạt động

Theo dõi chặt chẽ quá trình để đảm bảo hoạt động trơn tru.

Tắt máy

Tắt máy khi quá trình nghiền hoàn tất.

Và khi sử dụng máy nghiền búa gỗ, hãy đảm bảo thực hiện vệ sinh và bảo trì thường xuyên để giữ cho thiết bị của bạn luôn ở tình trạng tốt và đạt hiệu suất cao nhất. Đảm bảo vận hành an toàn bằng cách tuân theo các hướng dẫn sử dụng phù hợp do nhà sản xuất cung cấp.

Ngoài ra, hãy lưu giữ hồ sơ vận hành và bảo trì để tham khảo và theo dõi hiệu suất của máy trong tương lai.

Màn hình máy nghiền búa

Chúng tôi trưng bày các loại máy nghiền búa đa kích thước vừa, cả loại vừa và nhỏ, như minh họa bên dưới.

Vai trò trong dây chuyền sản xuất than củi hoặc chế biến gỗ

Nó thường được sử dụng kết hợp với máy băm gỗ trống, máy nghiền tổng hợp và các thiết bị khác.

Máy nghiền búa gỗ có nhiệm vụ xử lý nguyên liệu thô đã qua xử lý thô thành các hạt mịn(mùn cưa), cải thiện năng suất và chất lượng sản phẩm.

Tính linh hoạt và khả năng tùy chỉnh của nó khiến nó trở thành một phần không thể thiếu trong dây chuyền sản xuất, cung cấp giải pháp hiệu quả cho chế biến gỗ và sản xuất than củi.

Máy sấy trống quay cho mùn cưa, vỏ gạo

Máy sấy quay, hay còn gọi là máy sấy trống, là thiết bị sấy…

Máy nghiền gỗ công nghiệp để làm mùn cưa

Máy nghiền gỗ, còn được gọi là máy làm mùn cưa hoặc…

Tại sao cần máy sấy trống mùn cưa trong sản xuất viên than củi và nhiên liệu sinh khối?

Trong quá trình sản xuất que than củi và que sinh khối, …

Sản phẩm hot

Máy đóng gói gối cho bao than shisha hookah

Máy đóng gói than shisha, thực chất là đóng gói dạng gối…

Máy đóng gói than BBQ định lượng

Máy đóng gói than nướng BBQ được sử dụng để đóng gói…

Máy nghiền Raymond cho nghiền bột than

Máy nghiền Raymond dùng để nghiền và xay than…

Máy làm than cho sản xuất than từ vỏ dừa

Máy sản xuất than vỏ dừa được thiết kế để…

Máy cưa gỗ cho cắt khúc gỗ

Máy cưa gỗ được thiết kế để xử lý các khúc gỗ…

Máy làm than hookah quay cho than shisha tròn & vuông

Máy than hookah quay đặc biệt để…

Máy ép viên hình tổ ong cho ép than

Máy ép bánh hình tổ ong của chúng tôi là thiết bị chuyên dụng cho…

Máy sấy trống quay cho mùn cưa, vỏ gạo

Máy sấy trống quay dùng để sấy nhiều loại…

Lò nung than liên tục để bán

Lò carbon hóa liên tục được dùng đặc biệt để chuyển đổi…