Linea di produzione di bricchette di carbone

Impianto di lavorazione del carbone | Macchina per bricchette di carbone

Linea di produzione di bricchette di carbone

Impianto di lavorazione del carbone | Macchina per bricchette di carbone

Caratteristiche in breve

Sommario

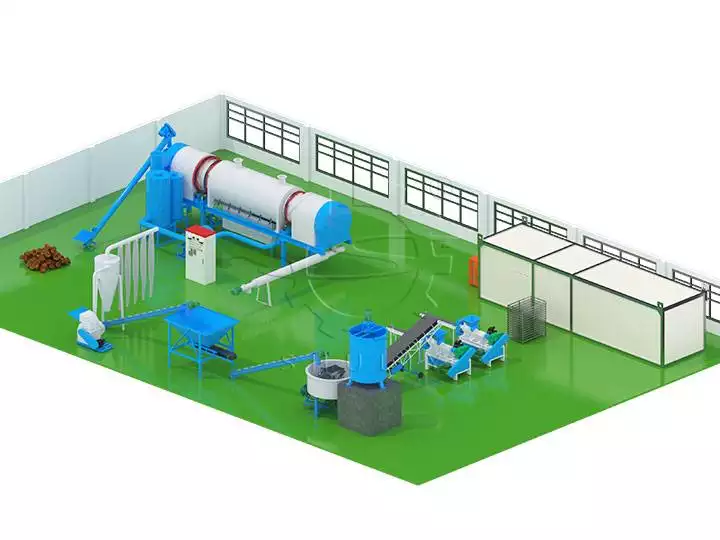

La linea di produzione di bricchette di carbone viene utilizzata per convertire materie prime come cippato di legno, segatura, gusci di cocco, lolla di riso, ecc. in bricchette di carbone con una capacità di 2t/giorno, 5t/giorno e 10t/giorno.

Il processo di base per la produzione di carbone è carbonizzazione→frantumazione del carbone→macinazione del carbone→miscelazione e macinazione della polvere di carbone→produzione di bricchette di carbone→essiccazione del carbone→imballaggio delle bricchette di carbone.

Questo impianto di lavorazione del carbone ha un alto grado di automazione, che può migliorare notevolmente l'efficienza della produzione di carbone e ridurre l'impiego di risorse umane. Fornisce una soluzione efficiente per gli investitori nella produzione di carbone.

Processo di produzione del carbone

Passaggio 1: carbonizzazione

Carbonizzare la materia prima utilizzando il forno di carbonizzazione ad alta temperatura.

Scegliere un forno a carbone adatto in base alle materie prime.

- Se si tratta di tronchi di legno, va bene la macchina carbonizzatrice verticale o orizzontale.

- Se lolla di riso o segatura, il forno di carbonizzazione continua è meglio.

Fase 2: frantumazione del carbone

Poiché la dimensione del carbone lavorato sopra varia, è necessario utilizzare il frantumatore di carbone per polverizzare il carbone.

Dopo la frantumazione, la dimensione del carbone è adatta per la fase successiva della lavorazione.

Fase 3: macinazione del carbone

Il carbone tritato deve essere nuovamente macinato.

Utilizzare il mulino Raymond per frantumare il carbone a 3-5 mm, pronto per lo stampaggio del carbone.

Fase 4: macinazione e miscelazione della polvere di carbone

Poiché la polvere di carbone non ha viscosità, non prenderà forma senza l'aggiunta del legante.

Pertanto, è necessario aggiungere il legante e utilizzare il mulino a ruote per macinare e miscelare completamente. Il ruolo è:

- Mescolare completamente la polvere di carbone in modo uniforme.

- Compatta la polvere di carbone per aumentarne la densità.

Passaggio 5: estrusione delle bricchette

Quindi, attraverso la macchina per bricchette di carbone, la polvere di carbone viene estrusa e modellata.

La forma del prodotto finito è determinata dallo stampo, che può essere personalizzato in base alle esigenze dei clienti.

Fase 6: essiccazione delle bricchette di carbone

Le bricchette appena modellate hanno un certo grado di umidità, quindi è necessario l'essiccatore per bricchette di carbone.

Fase 7: confezionamento dei bricchetti

Dopo l'essiccazione, le bricchette devono essere confezionate per lo stoccaggio e la facile vendita.

In questo processo è necessaria una macchina per l'imballaggio con film termoretraibile.

Punti salienti della linea di produzione di bricchette di carbone

- Capacità di 2 t/g, 5 t/g e 10 t/g. La nostra linea di produzione di carbone può produrre 2t, 5t o 10t di carbone al giorno, il che è altamente efficiente e può soddisfare le esigenze della produzione di carbone su piccola, media o larga scala.

- Produzione di bricchetti di carbone esagonali o quadrati. La forma del prodotto finito è determinata dallo stampo. Disponiamo di una varietà di stampi che possono realizzare prodotti a base di carbone in varie forme, come esagonale, quadrata, a forma di stella, ecc.

- Abbinamento flessibile. In base alla richiesta e al budget del cliente, possiamo realizzare abbinamenti flessibili per la linea di macchine per carbone.

- Servizio di installazione in loco. Una volta che l'attrezzatura arriva al sito, possiamo organizzare l'installazione da parte dei tecnici della linea di produzione in loco.

Capacità disponibili delle linee di produzione di bricchette di carbone in vendita

Marca: Shuliy

Capacità: 2t/giorno, 5t/giorno, 10t/giorno

Configurazione: forno di carbonizzazione, frantumatore di carbone, mulino Raymond, miscelatore a ruote, macchina per bricchette di carbone, essiccatore per bricchette di carbone e macchina per l'imballaggio

Periodo di garanzia: 1 anno

Perché utilizzare la linea di produzione di bricchette di carbone?

- Ampie applicazioni delle bricchette di carbone. Questa linea di macchine per la produzione di carbone è in grado di produrre bricchette di carbone di alta qualità, ampiamente utilizzate in molti campi come barbecue, riscaldamento, caldaie e così via.

- Ottima soluzione per i produttori di carbone. L'eccellente qualità dei prodotti finiti e l'efficiente capacità produttiva rendono la linea di produzione di bricchette di carbone l'attrezzatura preferita da molti produttori di palline di carbone.

- Trasforma i rifiuti in tesori. Questa linea di produzione di bricchette di carbone è realizzata con materiali di scarto come legno, gusci di cocco, bucce di riso e così via. Aiuta i rifiuti a essere riciclati e riutilizzati, ottenendo profitti.

Casi di successo di linee di produzione di carbone

Gestione del nostro impianto di lavorazione del carbone in Kenya

Il nostro cliente keniota ha acquistato la nostra linea di produzione di bricchette di carbone per produrre bricchette di carbone da vendere localmente.

Dopo aver ricevuto la macchina e averla utilizzata, questo cliente ha ritenuto che funzionasse molto bene, quindi ha inviato un video di feedback.

Consigli per la scelta di un impianto di lavorazione del carbone adatto

Quando si desidera acquistare una linea di produzione di bricchette di carbone adatta, è possibile fare riferimento ai seguenti punti per scegliere l'attrezzatura.

- Qualità e prestazioni dell'attrezzatura

- Capacità ed efficienza

- Consumo energetico e tutela dell'ambiente

- Prestazione di prezzo e di costo

- Servizio post-vendita e supporto tecnico

- Installazione e funzionamento facili

- Costo di fornitura e manutenzione delle parti

- Reputazione e credibilità del produttore

Mettiti in contatto con noi adesso!

Stai cercando soluzioni su come effettuare la produzione di bricchette di carbone? Se sì, contattaci ora, il nostro impianto di lavorazione del carbone ti aiuterà a realizzare il tuo obiettivo.

Macchina per la produzione di briquette di carbone per impianto a carbone

La macchina per la produzione di bricchette di carbone viene utilizzata per produrre carbone modellato…

Macchina di essiccazione a batch per briquette, carbone a nido d'ape, carbone di narghilè

L'essiccatore per carbone Shuliy è un'attrezzatura di essiccazione che asciuga rapidamente…

Macchina per l'imballaggio con film termoretraibile per briquette di carbone

La macchina per l'imballaggio delle bricchette di carbone, in realtà un film termoretraibile…

Macchina per briquette di carbone da 500kg/h in vendita in Brasile

Congratulazioni! Il nostro cliente brasiliano ha ordinato 2 set di bricchette di carbone…

Esportazione di macchina per la produzione di briquette di carbone SL-140 in Kenya

Recentemente, un cliente del Kenya ha ordinato una pressa per bricchette di carbone SL-140…

Linea di produzione di carbone di biomassa da 1-3t/d venduta in Myanmar

Ultime notizie da Shuliy! Un cliente del Myanmar ha acquistato un…

Creatore di briquette di carbone converte il carbone in eccesso in Guatemala

In Guatemala, un imprenditore locale alla ricerca di un modo innovativo…

Esportazione di macchina per essiccazione del carbone in Libia

Recentemente, uno dei nostri clienti in Libia ha acquistato l’attrezzatura per il carbone…

Cliente del Senegal ha scelto la macchina estrusore di carbone Shuliy per espansione

In Senegal, un cliente lungimirante stava cercando un carbone…

20 set di macchine estrusori di briquette di carbone inviati in Indonesia

Nel 2023, 20 set di macchine estruditrici di bricchetti di carbone Shuliy…

Prodotto caldo

Macchina per segheria per il taglio di tronchi

La macchina segheria per legno è progettata per lavorare i tronchi…

Mola Raymond per la macinazione di polvere di carbone

Il mulino Raymond serve a frantumare e macinare il carbone…

Macchina di confezionamento quantitativa di carbone da barbecue

La macchina per l'imballaggio di carbone per barbecue è utilizzata per confezionare…

Pressa per tavolette di carbone di narghilè rotonde e cubiche

Questa macchina per carbone per shisha è per l’efficienza…

Forno orizzontale di carbonizzazione per produzione di carbone di legno

Il forno di carbonizzazione orizzontale è utilizzato per trasformare il legno…

Caricatore di carbone per tronchi di legno, carbone di bambù per gru

Il forno di carbonizzazione a sollevamento è in grado di carbonizzare tronchi,…

Macchina per la produzione di briquette di segatura per briquette Pini Kay

La macchina per bricchette di segatura serve a comprimere trucioli di legno,…

Macchina di essiccazione a batch per briquette, carbone a nido d'ape, carbone di narghilè

Questa macchina per l'essiccazione del carbone viene utilizzata per asciugare…

Macchina industriale per la triturazione di pallet in vendita

La macchina frantoio per legno di scarto è progettata per il trattamento di…