Kömür briket üretim hattı

Kömür İşleme Tesisi | Kömür Briket Makinası

Kömür briket üretim hattı

Kömür İşleme Tesisi | Kömür Briket Makinası

Bir Bakışta Özellikler

İçindekiler

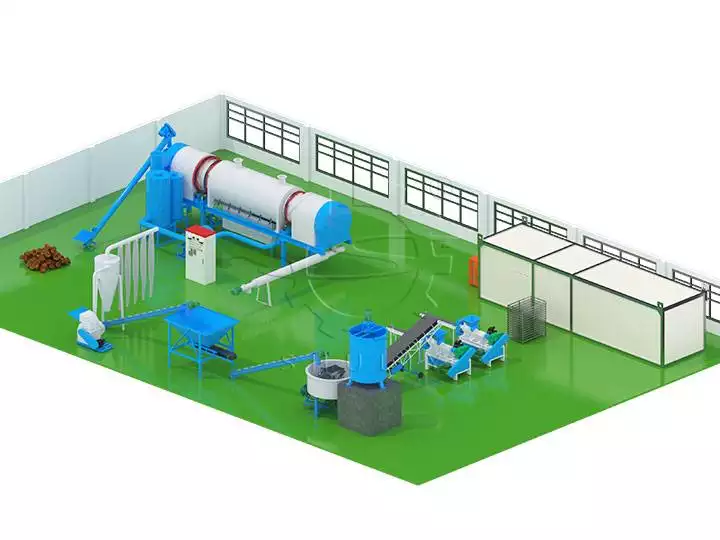

Odun kömürü briket üretim hattı, 2t/gün, 5t/gün ve 10t/gün kapasiteli, talaş, hindistan cevizi kabuğu, pirinç kabuğu gibi hammaddeleri odun kömürü briketlerine dönüştürmek için kullanılır.

Temel kömür yapma süreci karbonizasyon→kömür kırma→kömür öğütme→kömür tozu tekerlekli karıştırma ve öğütme→odun kömürü briket yapma→odun kömürü kurutma→odun kömürü briket paketleme şeklindedir.

Bu kömür işleme tesisi, kömür üretim verimliliğini büyük ölçüde artırabilen ve insan kaynakları girdisini azaltabilen yüksek derecede otomasyona sahiptir. Kömür üretimi yatırımcıları için etkin bir çözüm sunar.

Kömür yapma süreci

Adım 1: karbonizasyon

Hammaddeyi yüksek sıcaklıkta karbonizasyon fırınını kullanarak karbonize edin.

Hammaddelere göre uygun bir kömür fırını seçin.

- Tahta kütükler varsa, dikey veya yatay kömürleştirme makinesi iyidir.

- Pirinç kabuğu veya talaş varsa, sürekli karbonizasyon fırını daha iyi.

Adım 2: kömür kırma

Yukarıdaki işlemden geçen kömürün boyutu değişken olduğu için, kömürü öğütmek için kömür kırıcı kullanmak gerekir.

Kırma işleminden sonra kömür boyutu bir sonraki işlem adımına uygundur.

Adım 3: kömür öğütme

Ezilmiş kömürün tekrar öğütülmesi gerekiyor.

Kömürü, kömür kalıplaması için hazır hale getirmek üzere 3-5 mm'ye öğütmek için Raymond değirmeni kullanın.

Adım 4: kömür tozunun öğütülmesi ve karıştırılması

Kömür tozunun viskozitesi olmadığından bağlayıcı eklenmeden şekil almayacaktır.

Bu nedenle, bağlayıcı eklemek ve tam olarak öğütmek ve karıştırmak için tekerlekli değirmen öğütücü kullanmak gerekir. Rolü şunlardır:

- Kömür tozunun tamamen eşit şekilde karıştırılmasını sağlayın.

- Yoğunluğu artırmak için kömür tozunu sıkıştırın.

Adım 5: briketlerin ekstrüde edilmesi

Daha sonra, odun kömürü briket makinesi aracılığıyla, karbon tozu ekstrüde edilip şekillendirilir.

Bitmiş ürünün şekli, müşterilerin ihtiyaçlarına göre özelleştirilebilen kalıp tarafından belirlenir.

Adım 6: Kömür briket kurutma

Taze kalıplanmış briketler belirli bir nem derecesine sahiptir, bu nedenle odun kömürü briket kurutucu gereklidir.

Adım 7: briket paketleme

Briketler kuruduktan sonra depolama ve kolay satış için paketlenmelidir.

Bu işlemde bir ısı ile daralan film paketleme makinesi gereklidir.

Kömür briket üretim hattının öne çıkan özellikleri

- 2 ton/gün, 5 ton/gün ve 10 ton/gün kapasite. Kömür üretim hattımız günde 2 ton, 5 ton veya 10 ton kömür üretebilmektedir; bu, son derece verimlidir ve küçük, orta veya büyük ölçekli kömür üretiminin ihtiyaçlarını karşılayabilir.

- Altıgen veya kare kömür briket yapımı. Bitmiş ürünün şekli kalıp tarafından belirlenir. Altıgen, kare, yıldız şeklinde vb. çeşitli şekillerde kömür ürünleri yapabilen kalıp çeşitlerimiz mevcuttur.

- Esnek eşleştirme. Müşterinin talebine ve bütçesine göre kömür makine hattına esnek eşleştirme yapabilmekteyiz.

- Yerinde kurulum hizmeti. Ekipman sahaya ulaştığında, üretim hattını sahada kurmaları için mühendisler ayarlayabiliriz.

Satılık kömür briket üretim hatlarının mevcut kapasiteleri

Marka: Shuliy

Kapasite: 2t/gün, 5t/gün, 10t/gün

Yapılandırma: karbonizasyon fırını, kömür kırıcı, Raymond değirmeni, tekerlekli karıştırıcı öğütücü, odun kömürü briket makinesi, odun kömürü briket kurutucu ve paketleme makinesi

Garanti süresi: 1 yıl

Neden kömür briket üretim hattını kullanmalı?

- Kömür briketlerinin geniş uygulamaları. Bu kömür yapma makinesi hattı, barbekü, ısıtma, kazan vb. gibi birçok alanda yaygın olarak kullanılan yüksek kaliteli kömür briket ürünleri üretebilmektedir.

- Kömür üreticileri için harika bir çözüm. Mükemmel bitmiş ürün kalitesi ve verimli üretim kapasitesi, kömür briket üretim hattını birçok kömür topu üreticisi için tercih edilen ekipman haline getirmektedir.

- Atıkları hazineye dönüştürün. Bu kömür briket üretim hattı, ahşap, hindistancevizi kabukları, pirinç kabuğu vb. gibi atık malzemelerden yapılmıştır. Atıkların geri dönüştürülmesine ve yeniden kullanılmasına yardımcı olarak kar elde edilmesini sağlar.

Başarılı kömür üretim hattı vakaları

Kenya'da odun kömürü işleme tesisimizi çalıştırıyoruz

Kenyalı müşterimiz, yerel olarak satışa sunulan kömür briketleri üretmek için kömür briket üretim hattımızı satın aldı.

Bu müşteri, makineyi alıp kullandıktan sonra makinenin çok iyi çalıştığını hissetti ve bir geri bildirim videosu gönderdi.

Uygun bir kömür işleme tesisi seçmeye ilişkin ipuçları

Uygun bir kömür briket üretim hattı satın almak istediğinizde ekipmanı seçmek için aşağıdaki noktalara başvurabilirsiniz.

- Ekipman kalitesi ve performansı

- Kapasite ve verimlilik

- Enerji tüketimi ve çevre koruma

- Fiyat ve maliyet performansı

- Satış sonrası servis ve teknik destek

- Kolay kurulum ve çalıştırma

- Parça temini ve bakım maliyeti

- Üreticinin itibarı ve güvenilirliği

Şimdi bizimle iletişime geçin!

Odun kömürü briketleri üretimi konusunda çözümler mi arıyorsunuz? Evet ise, şimdi bize ulaşın, odun kömürü işleme tesisimiz hedefinize ulaşmanıza yardımcı olacaktır.

Kömür fırını için kömür briketleme makinesi

Odun kömürü briketi yapma makinesi, şekilli odun kömürü… yapmak için kullanılır.

Parti tipi kurutucu makine, bal peteği kömürü, nargile kömürü

Shuliy odun kömürü kurutma makinesi, hızlı bir şekilde kurutan kurutma ekipmanıdır…

Kömür kömürü için ısı daraltıcı film paketleme makinesi

Odun kömürü briket paketleme makinesi, aslında bir ısı büzüşmeli film…

Brezilya'ya satılık 500kg/s kömür kömürü makinesi

Tebrikler! Brezilyalı müşterimiz 2 set odun kömürü briketi… sipariş etti.

Kenya'ya SL-140 kömür kömürü pres makinesi ihracatı

Yakın zamanda, Kenya'dan bir müşteri SL-140 odun kömürü briketi… sipariş etti.

Myanmar'a satılan 1-3t/g biyokütle kömürü üretim hattı

Shuliy'e son dakika haberi! Myanmar'dan bir müşteri bir… satın aldı

Kömür kömürü yapıcı, Guatemala'da fazla kömürü dönüştürür

Guatemala'da, yenilikçi bir yol arayan yerel bir girişimci…

Libya'ya kömür kurutma makinesi ihracatı

Yakın zamanda, Libya'daki müşterilerimizden biri odun kömürü… satın aldı.

Senegalli müşteri, genişleme için Shuliy kömür ekstrüzyon makinesi seçti

Senegal'de, ileri görüşlü bir müşteri odun kömürü… arıyordu.

Endonezya'ya gönderilen 20 set kömür kömürü ekstrüzyon makinesi

2023'te, 20 adet Shuliy odun kömürü briketi ekstruder makinesi…

Sıcak Ürün

Kömür tozu öğütme ve karıştırma için tekerlek değirmen

Kömür tozu mikseri karıştırma ve… için kullanılır…

Barbekü kömürü topu pres makinesi

Shuliy kömür topu pres makinesi, basım için…

Hidrolik şişe kömürü pres makinesi

Bu nargile kömür pres makinesi verimli bir şekilde…

Shisha hookah kömürü paketleme yastığı makinesi

Nargile kömürü paketleme makinesi, aslında yastık paketlemedir…

Odun kesim makinesi

Odun değirmeni makinesi, tomrukları işlemek için tasarlanmıştır…

Odun kömürü yapımı için yatay karbonizasyon fırını

Yatay karbonizasyon fırını odun… dönüştürmek için kullanılır

Sürekli kömür fırını satılık

Sürekli karbonizasyon fırını özellikle… dönüştürmek için kullanılır

Endüstriyel çekiçli değirmen, odun parçalama için

Tahta çekiçli değirmen, odun dallarını öğütmek için…

Kömür fırını için kömür briketleme makinesi

Kömür briketi yapma makinesi… yapmak için kullanılır