Lini produksi arang biomassa 1-3t/hari dijual ke Myanmar

Daftar isi

Berita terbaru untuk Shuliy! Seorang klien dari Myanmar membeli lini produksi arang biomassa dengan kapasitas 1-3t/d. Lini mesin pembuatan arang ini cocok untuk pemula baru dan pengusaha arang skala kecil, jadi, jika Anda seorang pendatang baru di industri arang, ini adalah lini yang ideal untuk Anda.

Mengapa memulai bisnis arang segar?

Di negara Myanmar yang indah, seorang pelanggan akhir yang visioner menyadari potensi permintaan pasar untuk arang dan memutuskan untuk memulai bisnis arang segar. Dia melihat bahwa impian ini bisa terwujud melalui lini produksi arang biomassa. Oleh karena itu, dia ingin belajar dan membeli lini produksi arang.

Solusi untuk klien Myanmar

Kami menyediakan pelanggan ini dengan lini produksi arang biomassa untuk memenuhi kebutuhannya. Mengingat ukuran bisnis dan target volume produksi, kami mengirimkan penawaran untuk berbagai volume produksi arang sehingga dia dapat membuat keputusan yang tepat sesuai dengan anggaran dan rencananya.

Kami berkomunikasi secara efektif dengan klien dan dengan sabar menjawab semua pertanyaan dan kekhawatirannya. Kami memperoleh pemahaman mendalam tentang kebutuhan dan sasarannya serta menyesuaikan solusi lini produksi yang sesuai untuknya sesuai dengan kebutuhannya. Ditampilkan seperti di bawah ini:

Konfigurasi mesin untuk Myanmar memproduksi arang

| SN/T | Barang | Spesifikasi | Jumlah |

| 1 | Mesin penghancur kayu | Model:500 Daya: 18.5kw Kapasitas: 500-600kg per jam Pisau: 4 buah | 1 buah |

| 2 | Konveyor sabuk | Model:500 Daya: 2.2kw Panjang: 5m | 1 buah |

| 3 | Penghancur palu | Model: SL-700 Daya: 22kw Kapasitas: 700-800kg per jam Palu: 40 buah Diameter topan: 1m Termasuk 5 kantong penghilang debu Ukuran akhir: kurang dari 5mm | 1 buah |

| 4 | Konveyor sekrup | Dimensi: 5m*0,3m*0,5m Kekuatan: 4kw | 1 buah |

| 5 | Pengering putar | Model: SL-R800 Daya:4kw Kapasitas: 700-800kg per jam Diameter:800mm Panjang: 8m Berat: 2500kg Ketebalan: 8mm Gunakan limbah kayu atau batu bara sebagai sumber pemanas Per jam membutuhkan sumber pemanas 40-80kg | 1 buah |

| 6 | Berpendingin udara | Model:325 Daya: 7.5kw Termasuk kunci udara Dimensi: 7*0,6*3,8m | 1 buah |

| 7 | Konveyor sekrup | Dimensi: 5m*0,3m*0,5m Kekuatan: 4kw | 1 buah |

| 8 | Pengumpan sekrup | Model: SL-3 Dapat memberi makan tiga mesin briket serbuk gergaji Daya: 4kw Dimensi: 4*0,6*1,9m Termasuk sampul Termasuk kabinet kontrol listrik | 1 buah |

| 9 | Mesin briket serbuk gergaji | Model: SL-50 Daya: 18.5kw Kapasitas: 250kg per jam satu set Dimensi: 1770*700*1450mm Berat: 950kg | 3 set |

| 10 | Penghapusan asap | Kekuatan: 4kw Berat: 250kg Dimensi: 4500*700*700mm Termasuk kipas angin Peralatan pemurnian asap | 1 buah |

| 11 | Konveyor sabuk jala | Panjang: 4,5m Lebar: 0,8m Tinggi: 0,6m Kekuatan: 3kw Termasuk kabinet kontrol listrik | 1 buah |

| 12 | Mengangkat tungku karbonisasi | Model: SL-1500 Dimensi: 2,2*2,2*2,22m Kapasitas: 1t arang keluaran per waktu, membutuhkan 8-10 jam per waktu Termasuk 2 tungku, 1 derek angkat Ketebalan kompor bagian dalam: 8mm Per kompor membutuhkan sekitar 50-80kg sumber pemanas Dapat menggunakan limbah kayu atau batu bara sebagai sumber pemanas | 2 set |

Untuk kelancaran jalannya lini produksi arang biomassa, kami juga menyediakan aksesori mesin hammer mill dan mesin briket serbuk kayu.

| Mesin | Barang | Spesifikasi | Jumlah |

| Pabrik palu | Palu | Seumur hidup: sekitar 2-3 bulan 1 set termasuk 40 palu | 3 set |

| Seperti di atas | Layar | Seumur hidup: sekitar 6 bulan | 2 set |

| Mesin briket serbuk gergaji | Baut | Waktu angkat: 2-3 bulan | 3 buah |

| Seperti di atas | Cincin pemanas | Seumur hidup: 5-6 bulan 1 set termasuk 3 cincin pemanas | 1 set |

| Seperti di atas | Cetakan | 3 buah |

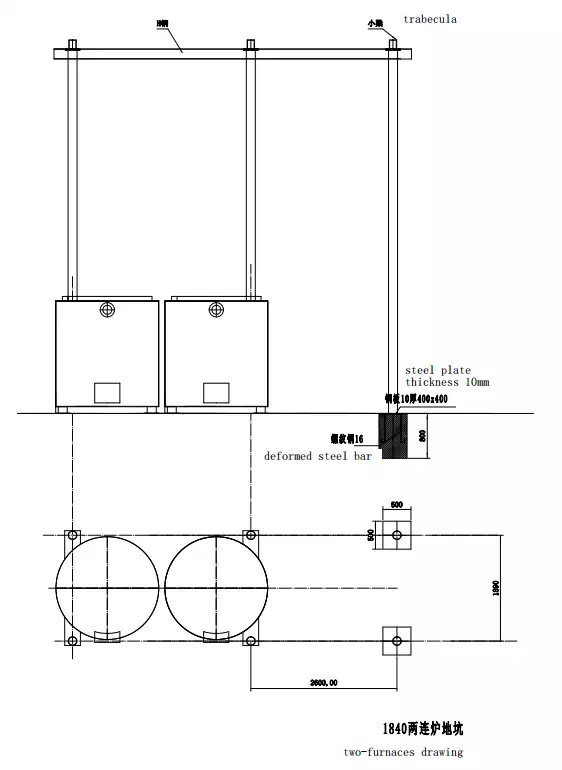

Untuk memastikan pelanggan puas dengan desain jalur produksi, kami juga menyediakan gambar detail sehingga dia dapat memahami keseluruhan proses dengan jelas.

Akhirnya, klien ini memesan seluruh lini produksi arang biomassa dari kami.

Memuat & mengirimkan lini produksi arang biomassa