1-3t/d biomass charcoal production line sold to Myanmar

Breaking news to Shuliy! One client from Myanmar bought a biomass charcoal production line with a capacity of 1-3t/d. This charcoal making machine line is suitable for the new starter and small-scale charcoal businessman, thus, if you’re a newcomer in the charcoal industry, it’s the ideal line for you.

Why start the fresh charcoal business?

In the beautiful country of Myanmar, a visionary end customer recognized the potential market demand for charcoal and he decided to start a fresh charcoal business. He saw that this dream could be realized through a biomass charcoal production line. Thus, he wanted to learn and buy the charcoal production line.

Solution for Myanmar client

We provided this customer with a biomass charcoal production line to meet his needs. Considering the size of the business and the target production volume, we sent him a quotation for different charcoal production volumes so that he could make an informed decision according to his budget and plan.

We communicated effectively with the client and patiently answered all his questions and concerns. We gained an in-depth understanding of his needs and goals and customized a suitable production line solution for him according to his requirements. Shown as below:

Machine configuration for Myanmar to produce charcoal

| S/N | Item | Specifications | Qty |

| 1 | Wood crusher machine | Model:500 Power:18.5kw Capacity:500-600kg per hour Blades:4 pcs | 1 pc |

| 2 | Belt conveyor | Model:500 Power:2.2kw Length:5m | 1 pc |

| 3 | Hammer crusher | Model: SL-700 Power:22kw Capacity:700-800kg per hour Hammers:40 pcs Cyclone diameter:1m Includes 5 bags dust removal Final size: less than 5mm | 1 pc |

| 4 | Screw conveyor | Dimension: 5m*0.3m*0.5m Power:4kw | 1 pc |

| 5 | Rotary dryer | Model: SL-R800 Power:4kw Capacity:700-800kg per hour Diameter:800mm Length:8m Weight:2500kg Thickness:8mm Use waste wood or coal as a heating source Per hour need 40-80kg heating source | 1 pc |

| 6 | Air-cooled | Model:325 Power:7.5kw Including a airlock Dimension:7*0.6*3.8m | 1 pc |

| 7 | Screw conveyor | Dimension: 5m*0.3m*0.5m Power:4kw | 1 pc |

| 8 | Screw feeder | Model: SL-3 Can feed three sawdust briquette machine Power:4 kw Dimension:4*0.6*1.9m Including a cover Including an electric control cabinet | 1 pc |

| 9 | Sawdust briquette machine | Model: SL-50 Power:18.5kw Capacity:250kg per hour one set Dimension:1770*700*1450mm Weight:950kg | 3 sets |

| 10 | Smoke removal | Power:4kw Weight:250kg Dimension:4500*700*700mm Including fan Smoke purification equipment | 1 pc |

| 11 | Mesh belt conveyor | Length:4.5m Width:0.8m Height:0.6m Power:3kw Including the Electric control cabinet | 1 pc |

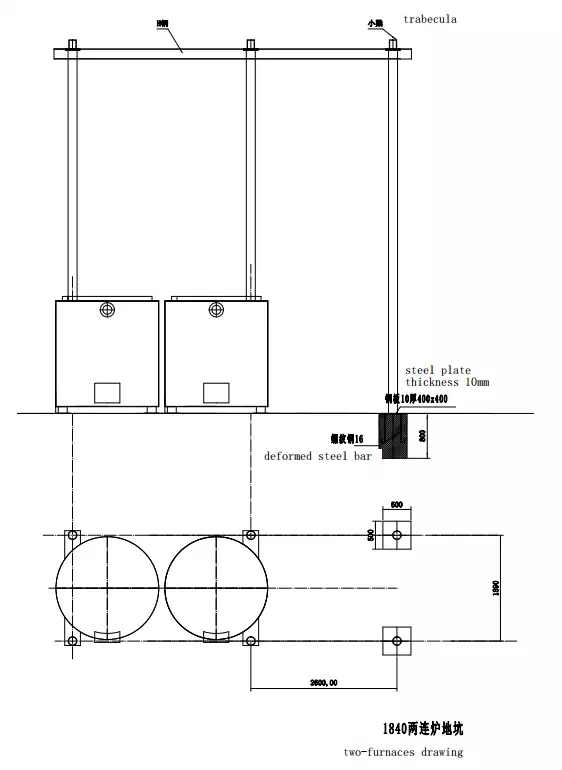

| 12 | Hoisting carbonization furnace | Model: SL-1500 Dimension:2.2*2.2*2.22m Capacity:1t output charcoal per time, need 8-10 hours per time Includes 2 furnaces,1 lift crane Inner stove thickness:8mm Per stove need about 50-80kg heating source Can use waste wood or coal as a heating source | 2 sets |

For the smooth running of the biomass charcoal production line, we also provide the accessories of hammer mill machine and sawdust briquettes machine.

| Machine | Item | Specifications | Qty |

| Hammer mill | Hammers | Lifetime: about 2-3 months 1 set including 40 hammers | 3 sets |

| As above | Screen | Lifetime: about 6 months | 2 sets |

| Sawdust briquettes machine | Screw | Lifttime:2-3 months | 3 pcs |

| As above | Heating ring | Lifetime:5-6 months 1 set including 3 heating rings | 1 set |

| As above | Mould | 3 pc |

To ensure that the customer was satisfied with the design of the production line, we also provided detailed drawings so that he could clearly understand the entire process.

Eventually, this client ordered the wholes biomass charcoal production line from us.

Load & deliver biomass charcoal production line