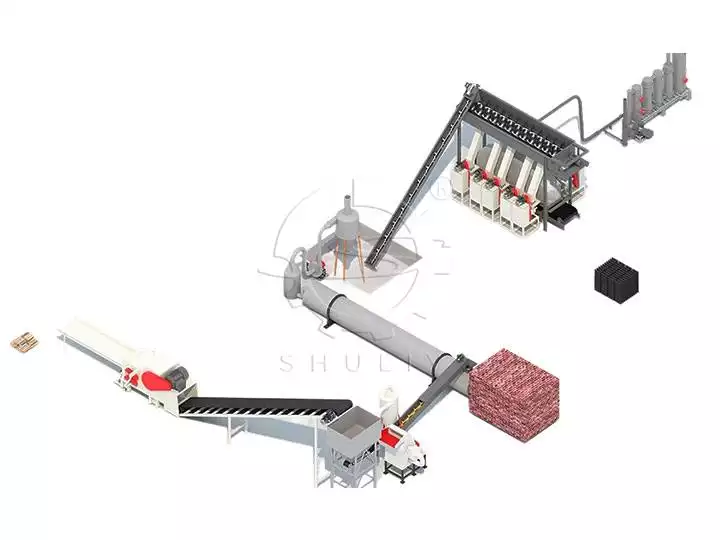

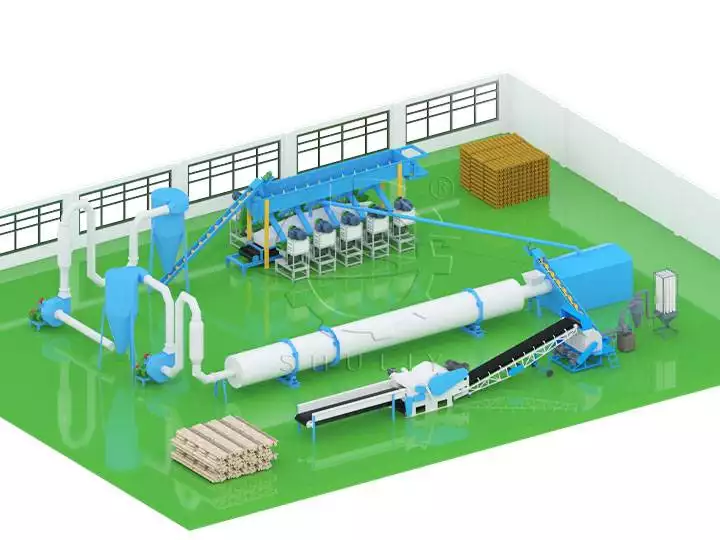

สายการผลิตขี้เลื่อยอัดก้อนสำหรับการรีไซเคิลชีวมวล

เครื่องอัดก้อนขี้เลื่อย | เครื่องอัดก้อนชีวมวล

สารบัญ

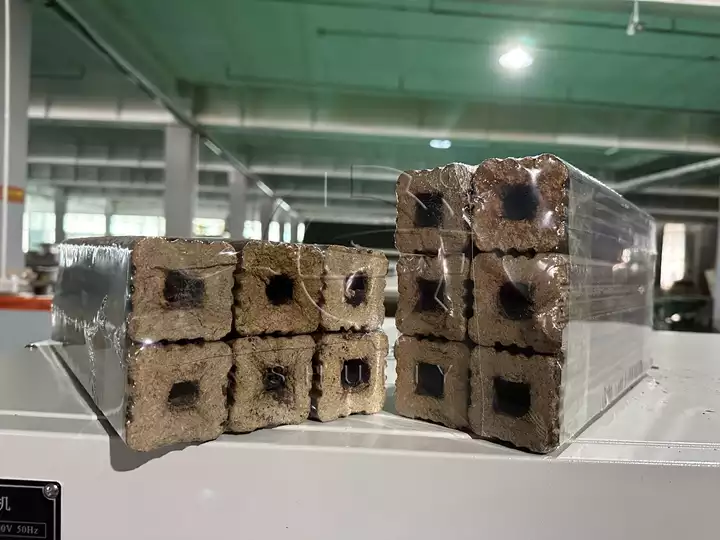

สายการผลิตอัดแท่งขี้เลื่อยของ Shuliy ใช้สำหรับอัดวัสดุชีวมวล เช่น ขี้เลื่อย เศษไม้ ฟาง แกลบ และอื่นๆ ให้เป็นแท่งกลวง ผลิตภัณฑ์สุดท้ายสามารถใช้เป็นเชื้อเพลิง ให้ความร้อน หรือทำถ่านอัดแท่งขี้เลื่อยได้

เครื่องอัดก้อนขี้เลื่อย 1 เครื่องมีความจุ 250 กก./ชม. หากคุณต้องการความจุขนาดใหญ่ วิธีแก้ปัญหาคือใช้เครื่องอัดก้อน pini kay หลายเครื่อง

วัตถุดิบในการผลิตชีวมวลอัดก้อน

วัตถุดิบที่ใช้ในสายการผลิตอัดแท่งขี้เลื่อย ได้แก่ **ขี้เลื่อย เศษไม้ ขี้กบ แกลบ ฟาง ขี้กากอ้อย เปลือกถั่ว** เป็นต้น

ข้อกำหนดสำหรับวัตถุดิบมีดังต่อไปนี้

- ขนาด: 3-5มม.

- ความชื้น: ≤12%.

หลังจากการอัดก้อนแล้ว ขี้เลื่อยอัดแท่งจะถูกใช้กันอย่างแพร่หลายในการทำความร้อนในครัวเรือน เชื้อเพลิงอุตสาหกรรม บาร์บีคิว และสาขาอื่นๆ

ขั้นตอนการทำขี้เลื่อยอัดก้อน

หลังจากทำความเข้าใจกับวัตถุดิบแล้ว เรามาดูวิธีการผลิตอิฐมวลชีวภาพจำนวนมากกัน

ขั้นตอนที่ 1: การบด

เนื่องจากวัตถุดิบมีขนาดใหญ่ เครื่องบดค้อนประเภทนี้จึงใช้ในการบดและย่อยวัสดุไม้ให้เป็นขี้เลื่อยขนาด 3-5 มม.

ขั้นตอนที่ 2: การอบแห้ง

หลังจากบดแล้ว ขี้เลื่อยจะมีความชื้นอยู่ ดังนั้นจึงต้องใช้เครื่องอบแห้งขี้เลื่อยในกระบวนการนี้ ควรทำให้ขี้เลื่อยแห้งโดยมีความชื้น ≤12%

ขั้นตอนที่ 3: การอัดก้อน

จากนั้น ขี้เลื่อยจะถูกนำเข้าเครื่องอัดแท่งขี้เลื่อยเพื่อรีดเป็นแท่ง Pini Kay ที่มีรูปร่าง

ขั้นตอนที่ 4: บรรจุภัณฑ์

สุดท้าย ใช้เครื่องบรรจุฟิล์มหดเพื่อบรรจุอัดแท่งขี้เลื่อย บรรจุภัณฑ์ประเภทนี้จัดเก็บและขนส่งได้ง่าย

ข้อดีของสายการผลิต briquettes pini-kay

- ผลผลิต >250กก./ชม- สายการผลิตขี้เลื่อยอัดก้อนนี้มีกำลังการผลิตขั้นต่ำ 250 กิโลกรัมต่อชั่วโมง หากคุณต้องการความจุขนาดใหญ่ เพียงใช้เครื่องอัดก้อนขี้เลื่อยเพิ่ม

- ขี้เลื่อยอัดก้อน, เศษไม้ แกลบ ฯลฯ- สายการผลิตนี้สามารถแปรรูปขี้เลื่อย เศษไม้ เศษไม้ทางการเกษตร และอื่นๆ โดยให้ความยืดหยุ่นในการเลือกใช้วัตถุดิบ

- การปรับแต่ง- เราสามารถปรับแต่งโซลูชันที่ดีที่สุดสำหรับการผลิตอิฐก้อนขี้เลื่อยให้เป็นไปตามงบประมาณและข้อกำหนดด้านผลผลิตของคุณ

อุปกรณ์เสริมสำหรับสายการผลิตขี้เลื่อยอัดก้อน

เนื่องจากสายการผลิตประกอบด้วยอุปกรณ์ที่แตกต่างกัน อุปกรณ์เสริมของเครื่องจักรที่แตกต่างกันจึงมีรูปทรงไม่เหมือนกัน เช่น:

- โรงสีค้อน: ใบมีดและตะแกรง

- เครื่องอัดก้อนขี้เลื่อย: แหวนทำความร้อน สกรู และแม่พิมพ์

เมื่อคุณซื้อสายการผลิตอัดก้อนขี้เลื่อย คุณสามารถขออุปกรณ์เสริมเพิ่มเติมในกรณีฉุกเฉินได้ และเราจะให้คุณในราคาที่ดี

เหตุใดจึงเลือก Shuliy เป็นผู้จัดจำหน่ายสายการผลิตขี้เลื่อยไม้

- คุณภาพอุปกรณ์ที่มั่นคงและเชื่อถือได้.

- เราใช้วัสดุคุณภาพสูงและเทคโนโลยีขั้นสูงเพื่อให้มั่นใจถึงการทำงานที่มั่นคงในระยะยาวของเครื่องอัดก้อนชีวมวล

- บริการหลังการขายที่สมบูรณ์แบบ.

- Shuliy ให้บริการครบวงจร เช่น การติดตั้งและทดสอบการใช้งาน การฝึกอบรมทางเทคนิค และการบำรุงรักษาอุปกรณ์ เพื่อให้มั่นใจว่าลูกค้าไม่ต้องกังวล

- บริการที่กำหนดเอง.

- ตามความต้องการเฉพาะของลูกค้า เรานำเสนอโซลูชั่นที่ออกแบบเฉพาะเพื่อตอบสนองความต้องการการผลิตที่แตกต่างกัน

- ชื่อเสียงของลูกค้าที่ดี.

- ด้วยอุปกรณ์คุณภาพสูงและบริการที่เป็นเลิศ เราได้รับความไว้วางใจและคำชมเชยจากลูกค้าของเรา

จะรับโซลูชันที่ปรับแต่งเองได้อย่างไร

ด้วยขั้นตอนง่ายๆ เหล่านี้ คุณจะได้รับโซลูชันการผลิตที่ปรับให้เหมาะกับความต้องการในการรีไซเคิลชีวมวลของคุณ

- ติดต่อเรา: ติดต่อเราทาง WhatsApp/WeChat/tel อีเมล หรือสอบถามออนไลน์

- บอกความต้องการของคุณให้เราทราบ: แจ้งความต้องการในการผลิตของคุณ รวมถึงข้อมูลเกี่ยวกับผลผลิตที่คาดหวัง งบประมาณ ประเภทวัตถุดิบ ฯลฯ

- โซลูชันการออกแบบ: ตามความต้องการของคุณ ทีมงานมืออาชีพของเราจะออกแบบโซลูชันส่วนบุคคลสำหรับคุณ รวมถึงการเลือกอุปกรณ์และผังกระบวนการ

- การชำระเงิน: เมื่อการแก้ปัญหาเสร็จสิ้นคุณควรชำระเงินมัดจำหรือชำระเงินเต็มจำนวน (ตามที่กล่าวไว้)

- การผลิต: จากนั้นเราจะเริ่มการผลิตอุปกรณ์เพื่อให้แน่ใจว่ามีการส่งมอบผลิตภัณฑ์คุณภาพสูงตรงเวลา

- การจัดส่ง: หลังจากการผลิตอุปกรณ์เสร็จสิ้น เราจะจัดเตรียมการขนส่งเพื่อให้แน่ใจว่าอุปกรณ์จะถูกจัดส่งถึงคุณอย่างปลอดภัยและทันเวลา

ส่งเครื่องทำแท่ง Pini kay ไปยังสหราชอาณาจักรสำเร็จแล้ว

สำหรับลูกค้ารายนี้จากสหราชอาณาจักร เขามีความเข้าใจลึกซึ้ง...

คุณทำแท่งเศษไม้จากเศษไม้เสียอย่างไร?

เมื่อความตระหนักด้านสิ่งแวดล้อมเติบโตอย่างต่อเนื่อง วิธีที่สร้างสรรค์ในการเปลี่ยนรูป…

เครื่องอัดแท่งเศษไม้ของเราในสหราชอาณาจักรนำเทรนด์เชื้อเพลิงชีวมวล

ในสหราชอาณาจักร ความต้องการเชื้อเพลิงชีวมวลเพิ่มขึ้นเนื่องจาก…

เครื่องอัดเศษไม้สำหรับขายให้ยูกันดาเพื่อแปรรูปเศษไม้เป็นแท่งอัด

ลูกค้าชาวยูกันดาประสบปัญหากับปริมาณมากของ…

เครื่องขึ้นรูปเศษไม้และเครื่องอัดแท่งถ่านส่งไปยังแคนาดา

เมื่อเร็ว ๆ นี้ หนึ่งในลูกค้าชาวแคนาดาของเราเลือกที่จะซื้อ…

การจัดส่งเครื่องอัดแท่งชีวมวลไปบัลแกเรีย

ลูกค้าชาวบัลแกเรียของเรา operates a wood waste recycling plant with…

เครื่องอัดแท่งเศษไม้สำหรับทำแท่ง Pini Kay

เครื่องอัดก้อนขี้เลื่อย Shuliy(เครื่องอัดก้อนชีวมวล) สามารถกดเศษไม้,...

สินค้ายอดนิยม

เครื่องตัดเศษไม้แบบจานขนาดเล็กสำหรับการผลิตเศษไม้จำนวนมาก

เครื่องหั่นไม้แบบดิสก์ถูกออกแบบมาเพื่อสับไม้…

เครื่องชิช่าถ่านหมุนสำหรับถ่านชิช่าทรงกลมและทรงลูกบาศก์

เครื่องทำถ่านมะยมแบบโฮก้ฮะโดยเฉพาะเพื่อ…

เครื่องบรรจุถ่านบาร์บีคิวเชิงปริมาณ

เครื่องบรรจุถ่านไม้สำหรับปิ้งย่างใช้สำหรับบรรจุ…

เครื่องอัดแท่งเศษไม้สำหรับทำแท่ง Pini Kay

เครื่องอัดแท่งจากผงเลื่อยสำหรับอัดเศษไม้…

เครื่องบรรจุฟิล์มหดความร้อนสำหรับถ่านอัดแท่ง

เครื่องบรรจุถ่านไม้แบบบริเก็ต จริงๆ แล้วเป็นการห่อด้วยความร้อน…

เครื่องอัดแท่งรังผึ้งสำหรับอัดถ่าน

เครื่องอัดแท่งถ่านรังผึ้งของเราเป็นอุปกรณ์เฉพาะสำหรับ…

เครื่องปอกเปลือกไม้แนวตั้งสำหรับการลอกเปลือกไม้จากต้นไม้

เครื่องปอกไม้ออกแบบมาเพื่อลอกเอา…

เครื่องอบแห้งแบบหมุนสำหรับขี้เลื่อยและเปลือกข้าว

เครื่องอบแห้งแบบโรตารีย์มีไว้สำหรับอบแห้งถ่านชนิดต่างๆ…

เครื่องอัดพาเลทไม้

เครื่องผลิตพาเลทไม้อัดสำหรับการผลิตไม้กดอัด…