Pillow packaging machine for shisha hookah charcoal pack

Hookah Charcoal Packing Machine | Charcoal Bagging Machine

Pillow packaging machine for shisha hookah charcoal pack

Hookah Charcoal Packing Machine | Charcoal Bagging Machine

Features at a Glance

Table of Contents

The shisha charcoal packing machine, actually the pillow packaging machine, is a specialized packaging machine for hookah charcoal products.

The machine has the flexibility to pack both round and square pieces of hookah charcoal and the number of pieces per pack can be customized according to customer needs.

In addition, the hookah charcoal packaging machine can be customized to design packaging styles and patterns to add unique branding features to the product.

The use of shisha charcoal packing machine for automated packaging not only improves packaging efficiency and reduces labor costs, but also ensures the consistency and aesthetics of the packaging.

The charcoal bagging machine plays an important role in the production line of shisha charcoal, providing efficient and precise packaging solutions for enterprises.

Features of shisha charcoal packing machine

- Step motor control, bag length is set that cut, no need to adjust, save time and film.

- Human-machine interface, convenient parameter setting.

- Failure self-diagnosis function, fault display at a glance.

- High sensitivity photoelectric eye color tracking, digital input the sealing and cutting position, making the sealing and cutting position more accurate.

- Temperature-independent PID control is better suited to a variety of packaging materials.

- Positioning stop function, no sticking knife, no waste of wrapping film.

- The transmission system is simple, more reliable, and maintenance is more convenient.

- All control is realized by software, convenient for function adjustment and technology upgrading, and keeps advanced.

Cube & round shisha charcoal packaging machine for sale

Because it packs different shapes of hookah charcoal, it can also be called cubic hookah charcoal packaging machine and round shisha charcoal packaging machine respectively.

Our packaging machines are constantly updated to realize fast and precise packaging operation, ensuring that each piece of charcoal is packaged in a beautiful and sealed way.

If you are interested in our equipment, come to contact us!

Final products of charcoal bagging machine

The finished product of the shisha charcoal packing machine is a carefully packaged hookah charcoal product, whether it is a round piece or a square piece, which is put into customized bags.

These bags can be designed according to customer requirements and can be printed with brand logos, product information and various patterns to make the product more attractive and recognizable.

Why use Shuliy shisha charcoal packing machine?

Through the packaging of the shisha charcoal packing machine, the product is not only easier to carry and store, but also effective in preventing moisture and preserving freshness, ensuring that the hookah charcoal quality.

Such packaging not only improves the added value of the hookah charcoal products, but also increases the market competitiveness of the products, so that the enterprise can better meet the needs of consumers and enhance the brand image and sales performance.

Packing and shipping shisha charcoal bagging machine

Before shipment, we always pack the pillow packaging machine for safe delivery.

Technical specifications of shisha charcoal packing machine

| Model | SL-280 |

| Width of wrapping film | 100-280mm |

| Bag length | 80-300mm |

| Product height | 5-60mm (above 60mm according to customer’s requirement) |

| Diameter of film roll | Diameter of the film roll |

| Packing speed | 120 bags/min |

| Power | 220V50HZ 2.5kw, 220V 50HZ 0.75KW, 220V 50HZ 0.3KW(slicer) |

| Dimension | (L)4000×(W)900×(H)1500mm; (L)3700×(W)950×(H)1500mm |

| Total weight | 500kg |

This is a parameter table of common models for packing hookah charcoal for your reference. In addition, there are parameters of cubic hookah charcoal packaging machine available for your consideration.

| Model | SL-TH-250 |

| Power | 220V, 50/60HZ, 2.6KW |

| Packing speed | 40-330 packs/min |

| Machine size | (L)3770×(W)670×(H)1450mm |

| Film width | Max. 250mm |

| Bag length | 65-190mm or 120-280mm |

| Bag width | 30-110mm |

| Product height | Max.40mm |

| Roll film diameter | Max. 320mm |

If you want a complete and fully automatic production line for shisha charcoal, welcome to contact us! We will provide you with the optimal program according to your needs.

Round & cubic shisha charcoal tablet press machine

Shisha charcoal machine is for the efficient production of hookah…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to produce round…

Hydraulic shisha charcoal press machine

This kind of shisha charcoal press machine is to efficiently…

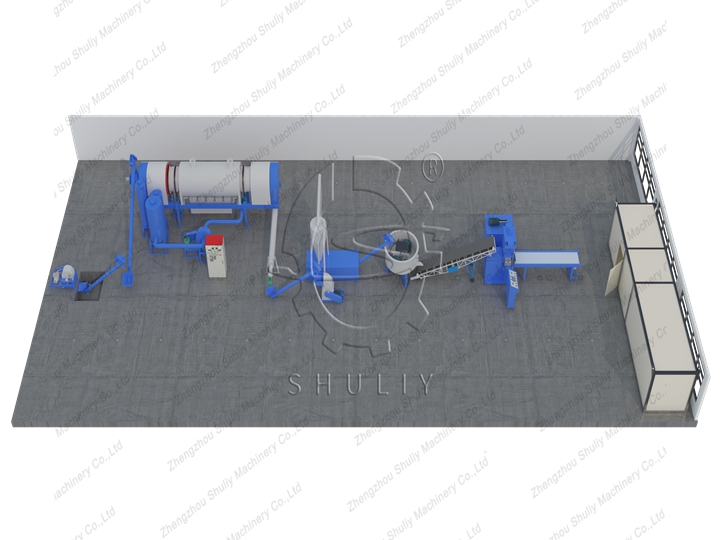

Round & cubic hookah shisha charcoal production line

Shuliy shisha charcoal production line is using wood waste, coconut…

Shisha charcoal briquette production line sold to Indonesia

We're glad to share that one Indonesian client bought a…

How to make shisha charcoal?

In today's market, to make shisha charcoal (high-quality water-smoked charcoal)…

Shisha charcoal tablet press for square hookah production in Oman

The Omani client was committed to developing a hookah charcoal…

What’s the shisha charcoal making machine price?

In the market of hookah charcoal, the price of shisha…

How much does a hookah charcoal machine cost?

In recent years, many entrepreneurs and factories are considering investing…

Two solutions of shisha charcoal production from Shuliy

Shisha charcoal is very popular in the charcoal market. Do…

Hot Product

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually pillow packaging…

Honeycomb briquette machine for coal pressing

Our honeycomb briquette machine is specialized equipment for…

Barbecue charcoal ball press machine

Shuliy charcoal ball press machine is for pressing…

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…

Vertical wood peeling machine for tree debark removal

Wood peeling machine is designed to remove the…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

This charcoal dryer machine is used to dry…

Sawdust briquette machine for Pini Kay briquettes making

Sawdust briquette machine is to press wood chips,…

Small disc wood chipper for mass wood chips making

Disc wood chipper is designed to chip wood,…