Round & cubic hookah shisha charcoal production line

Shisha Charcoal Making Machine | Charcoal Machine

Round & cubic hookah shisha charcoal production line

Shisha Charcoal Making Machine | Charcoal Machine

Features at a Glance

Table of Contents

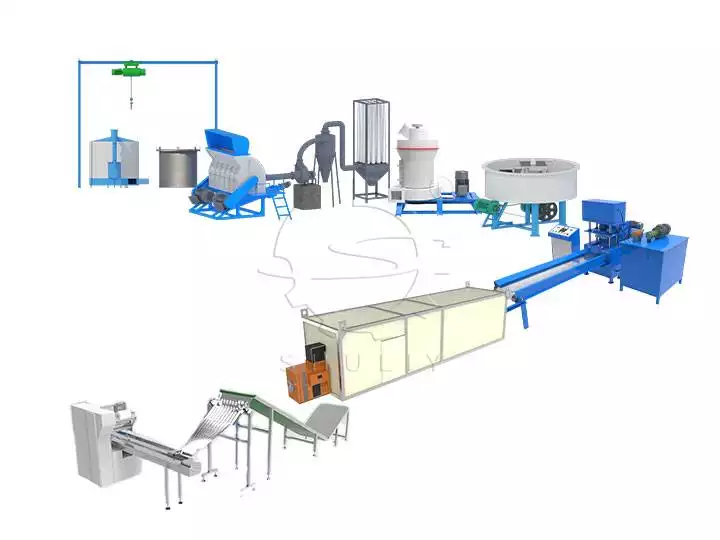

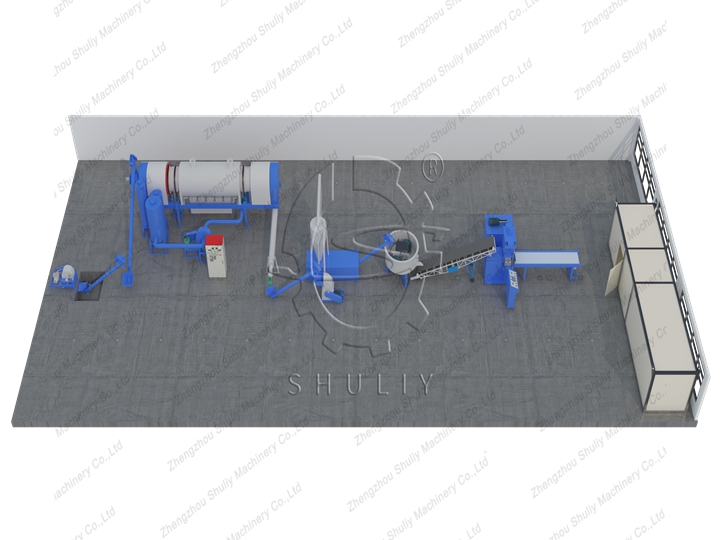

Shuliy shisha charcoal production line is using wood waste, coconut shells, rice hulls, bamboo, etc. into round or cubic hookah charcoal by carbonization and molding.

This shisha charcoal processing plant can make round or cubic hookah charcoal. The common sizes of round shisha charcoal are dia. 30mm, 33mm, 34mm, 35mm and 40mm. The common sizes of square hookah charcoal are 20*20*20mm and 25*25*25mm. We can also customize the size to meet your demands.

Because of its wide range of raw materials, quality finished products and high efficiency, our hookah charcoal machine line is popular in the hoohak bar, barbecue industry and fuel market.

If you want to start or expand your shisha charcoal business, our equipment is ideal for you.

How do you make shisha charcoal?

In this round & cubic shisha charcoal production line, the raw material is first carbonized and then molded. The detailed process is carbonizing→crushing→mixing and grinding→shisha charcoal making→drying→packing.

Stage 1: carbonizing

The first step is to carbonize the raw materials first. Choose the appropriate carbonization furnace according to the different raw materials. For example:

- The vertical carbonization machine is more suitable for wood logs, bamboo, etc.

- The continuous charcoal furnace is more suitable for coconut shells, rice husks, palm shells and so on.

Stage 2: charcoal crushing

The size of the raw material after carbonization is different, thus, the charcoal crusher is required. After crushing, the charcoal is proper for subsequent processing.

Stage 3: charcoal powder mixing and grinding

Making quality shisha charcoal requires carbon powder and binder, thus, the wheel mill grinder is the ideal equipment at this stage.

It can adequately grind and mix the charcoal powder and binder so that the charcoal powder has good adhesion and density when molding.

Stage 4: shisha charcoal making

After that, you need to use the shisha charcoal machine for tablet or cubic shisha charcoal making. As shown in the picture above, we have three kinds of machines for you to choose.

- Stainless steel hookah charcoal machine: corrosion-resistant, easy to clean, suitable for producing highly hygienic standard shisha charcoal.

- Hydraulic shisha charcoal making machine: high pressure, good molding effect, suitable for the production of high-hardness hookah charcoal.

- Rotary shisha charcoal tablet press machine: high efficiency, large output, suitable for large-scale continuous production.

You can choose the right one according to your needs. Or contact us, and we will give reasonable suggestions.

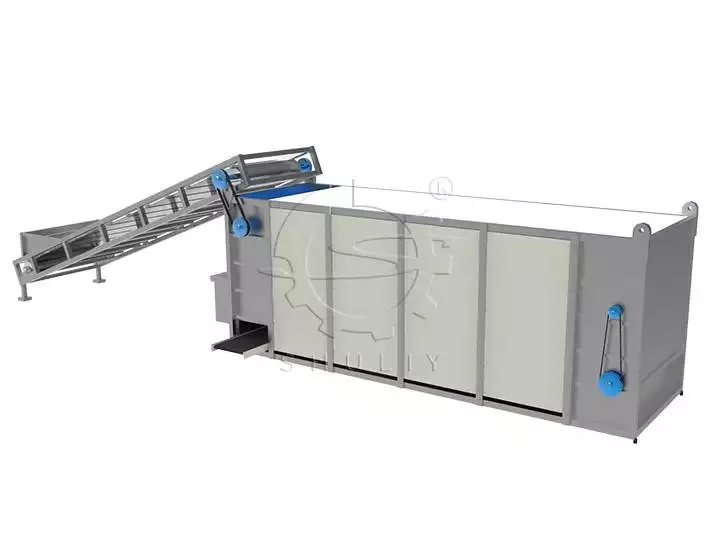

Stage 5: hookah charcoal drying

After production, the shisha charcoal contains moisture and needs to be dried.

Use the box-type charcoal briquette dryer to remove the excess moisture to ensure that it has good burning performance and moderate hardness.

Stage 6: charcoal bagging

Finally, the dried hookah charcoal is packaged with the pillow packing machine.

- The packed shisha charcoal is not damaged during transportation and storage.

- After packaging, the shisha charcoal has an attractive appearance, increasing sales.

Advantages of tablet & cubic shisha charcoal making machine line

- Output of 20,000pcs per hour. The shisha charcoal machine is the core part of the shisha charcoal processing plant. One machine can produce shisha charcoal of 20,000pcs per hour, which is a big yield.

- Wide applications of raw materials. For shisha charcoal briquette making, the proper raw materials include wood logs, wood shavings, wood chips, sawdust, coconut shells, rice hulls, palm shells, bamboo, etc.

- Multiple shisha charcoal sizes.

- Common sizes for round hookah charcoal sizes: dia. 30mm, 33mm, 34mm, 35mm, 40mm, etc.

- Common sizes for square shisha charcoal sizes: 20*20*20mm, 25*25*25mm, etc.

- We can also customize the charcoal size to meet your needs.

- Easy to operate. Shuliy shisha charcoal production line is mechanized and highly automated. It is very convenient to operate.

- Environmentally friendly. The entire processing line utilizes waste to minimize environmental pollution and harmful emissions, promoting sustainable green manufacturing practices.

What affects the shisha charcoal production line price?

The round & cubic shisha charcoal production line price is affected by many factors.

- First of all, the production capacity of the machine plays an important role in determining the price. Machines with higher production capacity are usually more expensive.

- Secondly, the material quality used in the construction of the shisha charcoal machine line will affect the price. High-quality materials and advanced technology may lead to higher costs.

- In addition, the level of automation and the complexity of the production process will also affect the price.

- Finally, factors such as brand reputation, after-sales service, and additional or customizable options may contribute to the overall price of a hookah charcoal production line.

Shuliy Machinery: a truthy shisha charcoal processing plant manufacturer

Shuliy has become a trusted charcoal machine manufacturer mainly because of the following points:

- Rich experience and expertise. Shuliy is the industry leader in charcoal machine design, manufacturing and sales with rich experience and expertise.

- Diversified product lines. We offer diversified product lines, including tablet and cube shisha charcoal production lines, etc., providing you with more choices.

- High-quality and stable equipment. Our equipment is high-quality, stable and reliable. They enjoy a good customer reputation and are highly evaluated by customers all over the world.

- Comprehensive service support. We provide a full range of service support, including pre-sales consultation and after-sales service, to ensure that you get the maximum value and satisfaction.

How to buy Shuliy shisha charcoal production line?

To purchase our shisha charcoal production line, you need to follow these simple steps.

- Demand communication. By Whatsapp, phone, or email, you send your demand and production target.

- Solution customization. According to your above needs, our sales team will customize a suitable solution for your shisha charcoal production, and provide detailed equipment configuration and quotation.

- Order confirmation. After confirming that the program and quotation are correct, we will sign the contract and confirm the order content.

- Pay the deposit. Pay the deposit as required by the contract to start the production process.

- Production and testing. We will start to produce the equipment according to the order. Carry out strict testing of the machine before leaving the factory to ensure stable equipment performance.

- Pay balance and shipping. After you check and accept the machine, pay the final payment. Then we arrange the shipment and provide logistics tracking information to ensure that the equipment reaches you safely.

- Installation and training. If necessary, we can send engineers for on-site installation and debugging to ensure that you can operate the production line skillfully.

- After-sales service. After the equipment is put into use, our after-sales team will provide continuous technical support to ensure the long-term and stable operation of the production line.

Round & cubic shisha charcoal tablet press machine

Shisha charcoal machine is for the efficient production of hookah…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to produce round…

Hydraulic shisha charcoal press machine

This kind of shisha charcoal press machine is to efficiently…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually the pillow packaging machine,…

Shisha charcoal briquette production line sold to Indonesia

We're glad to share that one Indonesian client bought a…

How to make shisha charcoal?

In today's market, to make shisha charcoal (high-quality water-smoked charcoal)…

Shisha charcoal tablet press for square hookah production in Oman

The Omani client was committed to developing a hookah charcoal…

What’s the shisha charcoal making machine price?

In the market of hookah charcoal, the price of shisha…

How much does a hookah charcoal machine cost?

In recent years, many entrepreneurs and factories are considering investing…

Two solutions of shisha charcoal production from Shuliy

Shisha charcoal is very popular in the charcoal market. Do…

Hot Product

Drum wood chipper machine for chips production

Drum wood chipper machine is designed to chip…

Vertical wood peeling machine for tree debark removal

Wood peeling machine is designed to remove the…

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Raymond mill for charcoal powder grinding

Raymond mill is to crush and grind charcoal…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

This charcoal dryer machine is used to dry…

Sawdust block making machine for wooden pallet blocks

The wood pallet block making machine is for…

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…