Hydraulic shisha charcoal press machine

Shisha Charcoal Tablet Press | Hookah Charcoal Making Machine

Hydraulic shisha charcoal press machine

Shisha Charcoal Tablet Press | Hookah Charcoal Making Machine

Features at a Glance

This kind of shisha charcoal press machine is to efficiently produce square or round hookah charcoal with the hydraulic tablet. This machine is often used in conjunction with a conveyor belt to automate the process.

It can make shisha charcoal with an output of 20-23 times/minute and 11 pieces/time, the sizes of final products are 33, 35, 38, 40, and 43 mm.

The machine has a separate control cabinet, which makes it more convenient and safe to use. If you’re interested in the hookah charcoal making machine, welcome to contact me for more details!

Table of Contents

Advantages of shisha charcoal press machine using hydraulic system

The hydraulic shisha charcoal press machine adopts hydraulic power, which has several advantages.

- Firstly, the hydraulic system can realize the transmission of high pressure, which makes the press molding more even and stable.

- Secondly, the hydraulic system responds quickly, making the production efficiency of the finished product greatly improved.

- In addition, hydraulic power can also realize precise control of the molding process, which guarantees the consistency of the quality of the finished product.

Technical parameters of hydraulic shisha charcoal making machine

Model: SLSS-1

Compression strength:100 kn

Press diameter: 33 35 38 40 43 mm

Production capacity: 20-23times/minute 11pieces/time

Overall dimension: 2500*900*1500 mm3

Packing size: 1400*1100*1650 mm3

Motor power: 7.5 kw

Host weight: 1500 kg

Structure of hydraulic shisha charcoal press machine

The structural design of the hydraulic hookah charcoal machine reflects the application of advanced technology.

| S/N | Machine part name | Function |

| 1 | PLC control system | the intelligent core of the whole machine, realizing the precise control of the automatic production process |

| 2 | Hydraulic pump | provide the power source, which powers the hydraulic cylinder through the hydraulic system to realize the pressing and molding of raw materials |

| 3 | Conveyor belt | convey the finished hookah charcoal |

The reasonable configuration and coordinated operation of these key components make the hydraulic shisha charcoal machine excel in efficient production.

Two types of conveyor belts for shisha charcoal tablet press machine

The mesh conveyor belt adopts a uniform grid structure to ensure smooth transfer and accurate positioning of the raw materials, and is often suitable for use together with the hydraulic hookah charcoal briquette press.

Belt conveyor, on the other hand, is powered by a stable conveyor belt and are sometimes used to transport finished products.

Workflow of Shuliy hydraulic hookah shisha charcoal tablet press

- Step 1: Feed the raw materials to the feeder. You can also use the elevator to send it to the feeder.

- Step 2: In the molding area, the hydraulic system starts to work to press and mold the raw materials to form the finished hookah charcoal products.

- Step 3: The finished products are pushed out through the back side baffle to facilitate subsequent processing and packaging.

The entire workflow is highly efficient and automated, guaranteeing continuous production and consistent quality of hookah charcoal.

Get a quote now!

Do you want to carry out the production of hookah charcoal? If so, contact us.

As a professional charcoal machine manufacturer, we not only have water-smoked charcoal machine, but also other supporting equipment, such as charcoal furnace, wheel mill, packing machine, etc., which constitute a complete charcoal production line for you to choose from.

Round & cubic shisha charcoal tablet press machine

Shisha charcoal machine is for the efficient production of hookah…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to produce round…

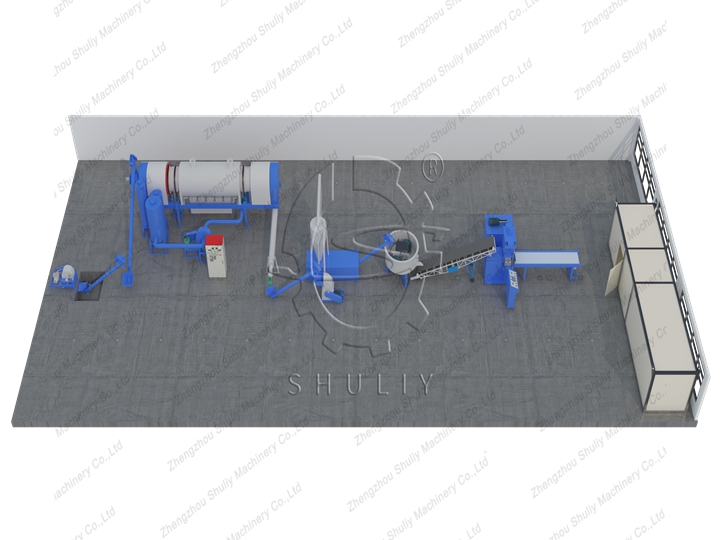

Round & cubic hookah shisha charcoal production line

Shuliy shisha charcoal production line is using wood waste, coconut…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually the pillow packaging machine,…

Shisha charcoal briquette production line sold to Indonesia

We're glad to share that one Indonesian client bought a…

How to make shisha charcoal?

In today's market, to make shisha charcoal (high-quality water-smoked charcoal)…

Shisha charcoal tablet press for square hookah production in Oman

The Omani client was committed to developing a hookah charcoal…

What’s the shisha charcoal making machine price?

In the market of hookah charcoal, the price of shisha…

How much does a hookah charcoal machine cost?

In recent years, many entrepreneurs and factories are considering investing…

Two solutions of shisha charcoal production from Shuliy

Shisha charcoal is very popular in the charcoal market. Do…

Hot Product

Barbecue charcoal ball press machine

Shuliy charcoal ball press machine is for pressing…

Quantitative BBQ charcoal packing machine

BBQ charcoal packaging machine is used to package…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…

Flat die feed pellet machine for animal feed making

Feed pellet machine is designed to produce high-quality…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

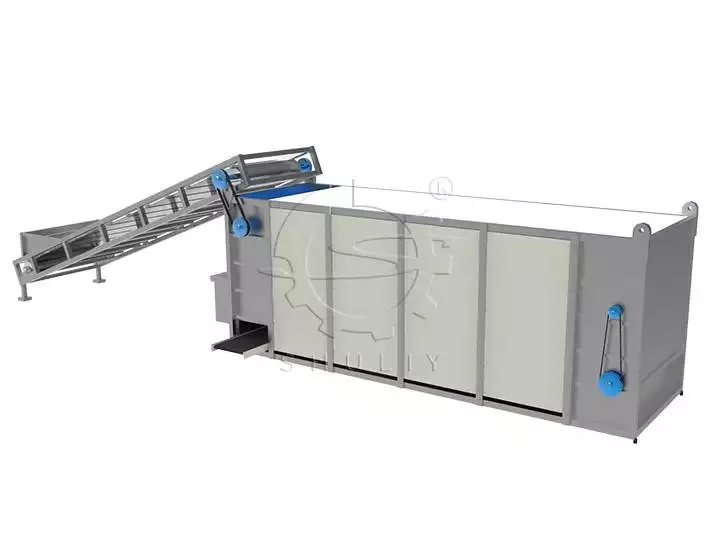

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…

Charcoal briquette making machine for coal plant

Charcoal briquette making machine is used to make…

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…