Barbecue charcoal ball press machine

BBQ Charcoal Making Machine | Coal Powder Briquetting Machine

Barbecue charcoal ball press machine

BBQ Charcoal Making Machine | Coal Powder Briquetting Machine

Features at a Glance

Table of Contents

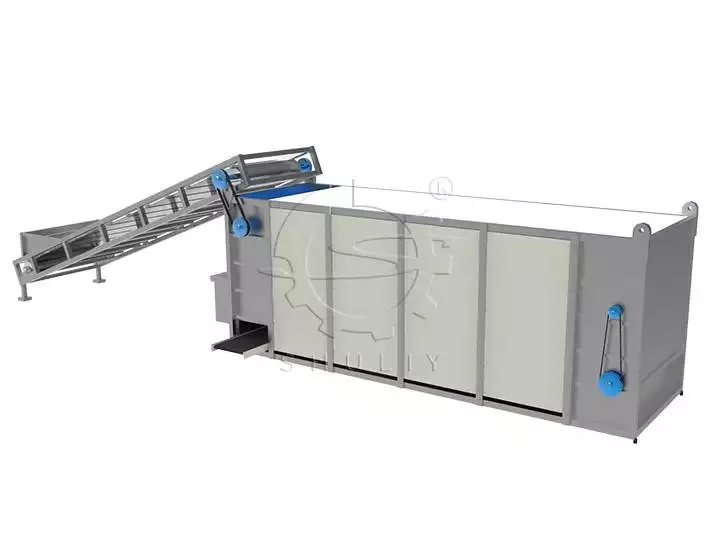

Shuliy charcoal ball press machine is a new type of equipment for pressing powdery materials, such as carbon powder and coal powder into BBQ charcoal as barbecue fuel.

It has a wide range of capacity: 2-40t per hour. This automatic coal powder ball press is widely used in power plant, metallurgy, chemical industry, energy, transportation, heating and other industries.

The materials molded by the coal ball press machine have the characteristics of energy saving, easy transportation, improving the utilization rate of waste materials, and at the same time have good economic and social benefits.

Raw materials used for Shuliy barbecue charcoal making machine

This ball press machine is multifunctional equipment that can handle many different raw materials. It is suitable for raw materials such as:

Coal powder, coal slurry, coke powder, coking coal, wood chips, charcoal, activated carbon, limestone, silica fume, calcium powder, bauxite, aluminum chips, iron powder, iron ore powder, copper powder, copper ore powder, zinc powder, zinc ore powder, tungsten powder, molybdenum powder, titanium powder, titanium ore powder, laundry detergent powder, chemical fertilizer, pigment powder, urea, ammonium nitrate, phosphate, potash, ammonium sulfate and so on.

These raw materials can be molded into solid products by this charcoal ball press machine.

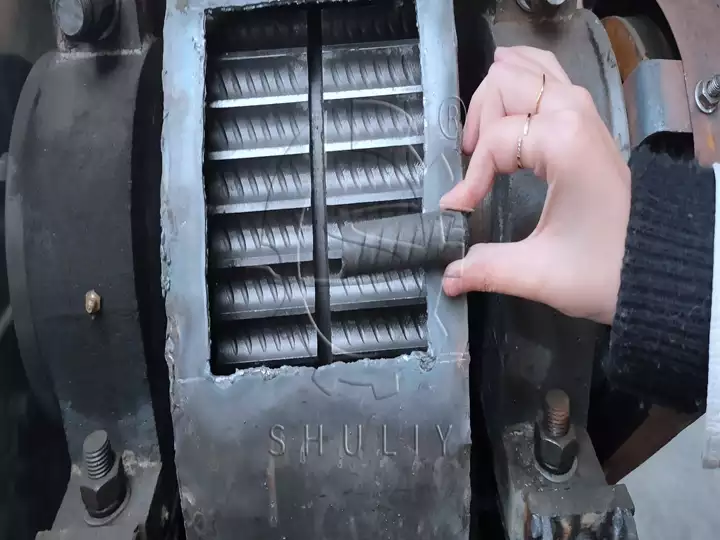

Moulds of BBQ charcoal ball press machine

Barbecue charcoal production requires a variety of molds to create different shapes of charcoal products. These molds come in a variety of sizes and designs to enable manufacturers to produce charcoal briquettes in different shapes such as cubes, cylinders, spheres, etc.

The molds are usually made of high-quality materials to ensure durability and precision in charcoal molding. With the flexibility offered by these molds, as a charcoal manufacturer, you can offer a range of BBQ charcoal to meet different market demands.

Finished products of BBQ charcoal ball pressing machine

The finished product of BBQ charcoal making machine is mainly in various shapes such as spherical, pillow, steel, oval and so on. This BBQ charcoal is made from high-quality charcoal material to ensure a clean and smokeless burning process, making it ideal for enhancing the BBQ experience and creating delicious meals.

Strengths of the charcoal ball press machine

- Multi-purpose function: Shuliy barbecue charcoal ball press machine has a wide range of applications, and can be used to press balls for a variety of materials, such as aluminum chips, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke chips, coal, cryolite, chemical fertilizer, plastics, limestone, pigment, urea, potash and so on, which realizes the function of multi-purpose of one machine.

- Energy saving: The coal powder briquetting machine effectively improves the utilization efficiency of coal resources and reduces the energy waste of coal in the combustion process. The charcoal molded by pressing can be fully burned during combustion, which reduces the emission of sulfur dioxide in the exhaust gas, and also greatly reduces the emission of dust and soot in the air.

- Reasonable structural design: The main machine of the charcoal ball press machine adopts an electromagnetic speed-regulating motor to provide power, which is transmitted to the main shaft through the belt pulley and cylindrical gear reducer. During the pressing process, it can maintain a constant supply pressure to ensure the stable quality of the ball.

Technical parameters of BBQ charcoal making machine

| Model | Output | Annual output | Motor power |

| SL-290 | 2T/H | 5000Ton | 5.5KW |

| SL-360 | 4 T/H | 10000Ton | 7.5 KW |

| SL-400 | 6 T/H | 15000 Ton | 11 KW |

| SL-430 | 7 T/H | 17000 Ton | 11 KW |

| SL-450 | 8 T/H | 20000 Ton | 15 KW |

| SL-500 | 10 T/H | 25000 Ton | 18.5 KW |

| SL-600 | 12 T/H | 30000 Ton | 22 KW |

| SL-650 | 14 T/H | 35000 Ton | 30 KW |

| SL-750 | 17 T/H | 40000 Ton | 37 KW |

| SL-800 | 20 T/H | 50000 Ton | 45 KW |

| SL-1200 | 40 T/H | 100000 Ton | 75 KW |

Applications of charcoal ball press machine

Based on the above, it’s clear that the ball press has a wide range of applications covering coal, metallurgy, chemical, energy, building materials and other industries, providing efficient and energy-saving pressing solutions for various industries.

Whether it is the reuse of waste materials or the processing of raw materials, the coal ball press machine has shown strong adaptability and application potential.

How does the BBQ ball press machine work?

Shuliy Machinery’s charcoal ball press machine adopts a pre-pressure screw, and the rotational speed is adjusted by the electromagnetic speed-regulating motor to meet the requirement of material forming.

The balling rate and capacity can be optimized by the adjustment of rotational speed. The pressed materials are screened by sieving machine, and the qualified charcoals are packed, while the screened materials can be mixed with new materials and pressed again.

In addition, the coal ball briquette machine is equipped with a hydraulic protection device, which will work to protect the pressure roller from damage when too much material is fed in or when there are metal blocks entering.

How to pack BBQ charcoal?

For effective packaging of BBQ charcoal, a quantitative packaging machine is used. This machine allows for fast and efficient packaging of barbecue charcoal.

The packaged barbecue charcoal is easy to store, transport and retail. In addition to this, the packaging provides protection from moisture and ensures that the charcoal remains fresh and ready for barbecue and other uses.

Powerful charcoal ball press machine manufacturer

Trust Shuliy Machinery, a powerful charcoal machine manufacturer, for all your charcoal briquette needs.

With years of industry experience and advanced technology, we offer high-quality charcoal ball press machines that efficiently produce charcoal briquettes for a variety of applications. Our machines are durable, reliable and easy to operate, providing you with a cost-effective charcoal production solution. Contact us soon if you need any assistance!

Global cases of coal ball press machine

Shuliy’s BBQ charcoal making machines have been successful worldwide, including the United States, Peru, the United Arab Emirates and Thailand. Our machines are trusted by customers around the world for their high efficiency, reliable performance and consistent quality of briquette production.

From large industrial applications to small businesses, our coal powder briquetting machine has had a positive impact on every market, making Shuliy Machinery the first choice for coal briquette pressing needs worldwide.

FAQ of barbecue charcoal ball press machine

What’s the raw material for the charcoal ball press machine?

Charcoal powder and coal powder. And other metal powder, soil, etc.

Can you customize the size of the ball press machine?

Yes, add some money, except for the regular one.

What shapes of pressed balls are?

Conventional ball, pillow, rugby ball. And we can also customize based on your needs.

How about the charcoal ball press machine capacity?

Minimum 1t per hour, conveyor belt transportation can reach 2t/h.

Contact Shuliy to get BBQ charcoal making machine solution

Shuliy charcoal ball press machine provides efficient pressing solutions for different industries through its multifunctional, energy-saving and reasonable structural design.

A variety of models are available for customers to choose from. The flow is as below:

- Firstly, contact me to arrange a professional sales manager to offer services to you;

- Secondly, the manager will provide the solution to you, according to your needs such as products size, mold requirements;

- Thirdly, if you’re satisfied, or have any questions, just ask and we will answer them one by one;

- Fourthly, everything is ok, you can place the order and pay the deposit;

- Fifthly, we will start production. Until the production is over, we will arrange the delivery after paying the balance.

Whether in industrial production or the energy industry, Shuliy’s coal powder briquetting machine shows excellent performance and wide application prospects.

Round & cubic shisha charcoal tablet press machine

Shisha charcoal machine is for the efficient production of hookah…

How to make rice husk charcoal?

Rice husk charcoal is a renewable and environmentally friendly energy…

Round & Pillow BBQ Charcoal Production line

Shuliy BBQ charcoal production line is to process charcoal balls…

Continuous drying machine for BBQ charcoal

The briquette dryer machine, also known as mesh belt dryer,…

Quantitative BBQ charcoal packing machine

BBQ charcoal packaging machine is a specialized device used to…

Deliver SL-290 BBQ coal ball press machine to Thailand

Great news for Shuliy! Our client from Thailand ordered a…

Successful install BBQ charcoal briquettes plant in Romania

Good news from Romania! Our client successfully installed and ran…

Charcoal ball pressing machine solves the problem of coal sales residue in Mexico

So happy to cooperate with the Mexican client about the…

Shuliy charcoal press machine exported to Indonesia

Our charcoal press machine helps recycle used wastes in Indonesia,…

Kenyan client bought 1-2t/h BBQ charcoal machine

A charcoal machine dealer from Kenya has been looking for…

Hot Product

Hydraulic shisha charcoal press machine

This shisha charcoal press machine is to efficiently…

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…

Flat die feed pellet machine for animal feed making

Feed pellet machine is designed to produce high-quality…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Industrial pallet crushing machine for sale

Waste wood crusher machine is designed for processing…

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…

Raymond mill for charcoal powder grinding

Raymond mill is to crush and grind charcoal…