Rotary hookah charcoal machine for round & cubic shisha charcoal

Shisha Charcoal Tablet Press Machine | Shisha Charcoal Machine

Rotary hookah charcoal machine for round & cubic shisha charcoal

Shisha Charcoal Tablet Press Machine | Shisha Charcoal Machine

Features at a Glance

Table of Contents

The rotary hookah charcoal machine is especially to produce round & cubic shisha charcoal using charcoal/carbon powder as raw materials. It has a production capacity of 40mm, 19 pieces per circle; 33mm and 20mm, 21 pieces per circle.

As a highly popular product among hookah charcoal machines, this kind of shisha charcoal machine has attracted a lot of attention in the hookah charcoal industry for its high production capacity, high efficiency and multi-functional features.

Whether you are a hookah bar, a hookah charcoal processor, or a user seeking high-quality hookah charcoal, our rotary hookah tablet press machine will bring you a production experience beyond your imagination.

Hookah charcoal size

There are a variety of options for common sizes of finished hookah charcoal.

- Square shisha charcoal: common sizes include 20*20*20mm and 25*25*25mm.

- Round hookah charcoal: common sizes include 30mm, 33mm, 34mm, 35mm and 40mm in diameter.

The variety of size options allows you to choose the right hookah charcoal product according to your actual needs and preferences, ensuring that they meet the requirements of various applications and enjoy a higher quality hookah charcoal experience.

Strengths of continuous hookah charcoal machine

- It can realize high production capacity and significantly improve production efficiency.

- Shuliy rotary hookah charcoal machine is easy to use and simple to operate, reducing labor and time costs.

- Shisha charcoal tablet press machine adopts advanced processing technology, which can produce finished hookah charcoal products with uniform specifications and regular shapes, and improve product quality.

- This kind of hookah charcoal machine is often used in conjunction with conveyor belts to automate production and better meet mass production needs.

Technical parameters of rotary hookah charcoal machine

Machine name: rotary shisha charcoal machine

Capacity: 40mm, 19 pieces per circle; 33mm and 20mm, 21 pieces per circle

Pressure: 120KN

Power: 7.5kw

Filling depth: 16-28mm

Charcoal thickness: 8-15mm

Turntable speed: max 30r/min, usually is 15r/min

Weight: 1500kg

Dimension: 800*900*1650mm

Final products: round & cubic shisha charcoal

Why is the rotary hookah charcoal machine popular?

There are several main reasons for the popularity of the rotary hookah charcoal press machine as a hot-selling product among hookah charcoal machines.

- Shuliy shisha charcoal tablet press has the advantage of high production capacity, which can produce a large amount of hookah charcoal products efficiently.

- The rotary hookah charcoal machine adopts advanced technology and design in the production process, which ensures the stability and reliability of the equipment.

- Most importantly, it is able to produce finished products suitable for use in different scenarios such as hookah charcoal, hookah bar/club, etc., which meets the needs of different customers.

Applications of hookah charcoal tablet press

Shuliy rotary hookah charcoal machine is widely used in the hookah charcoal industry and has become one of the most important equipment in many hookah bars and clubs.

These establishments require a large supply of hookah charcoal and the high throughput and efficiency of the rotary shisha charcoal tablet press machine makes it an ideal choice.

In addition, a number of hookah charcoal manufacturers and processors use rotary shisha charcoal tablet press machine to meet market demand, increase production capacity, and ensure product quality and consistency.

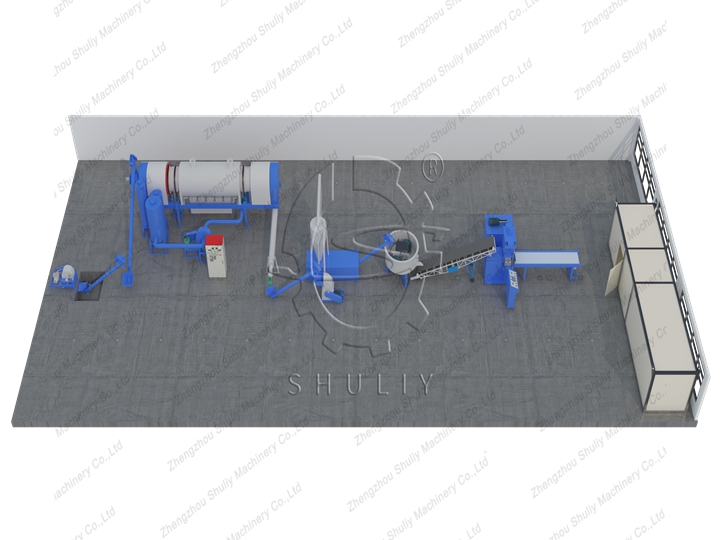

Working principle of rotary hookah charcoal press machine

The rotary hookah charcoal machine evenly fills the mold with toner and other raw materials through a rotating motion, and then presses them into the desired shape of hookah charcoal.

It is equipped with advanced pressing technology and an automated control system to ensure high density and regular shape of the finished product and high efficiency and stability of the production process.

When connected with the conveyor belt, it automatically conveys raw materials and finished products to improve production efficiency and make the whole production process more intelligent and convenient.

Value of investing in Shuliy rotary shisha charcoal machine

Choosing a rotary hookah charcoal machine is a wise investment. It not only meets the demands of large-scale hookah charcoal production and improves output and production efficiency, but also ensures the stability and consistency of finished product quality.

As an advanced hookah charcoal machine equipment, the use of Shuliy rotary hookah charcoal press machine will bring significant economic benefits and production advantages.

It is not only suitable for places such as hookah bars and clubs, but also provides better production solutions for hookah charcoal manufacturers and processors, helping them to achieve a greater advantage in the market competition.

How to package Shuliy hookah charcoal press machine?

To ensure the safety and integrity of the machines during transportation, we professionally pack them in wooden crates before shipping.

Wooden crate packaging can provide reliable protection against machine damage from collision, vibration or other external factors.

Well-designed wooden crate packaging, customized to the size and structure of the rotary hookah charcoal machine, ensures that the machine is firmly and securely fixed inside the crate to avoid shifting or tilting during transportation.

In this way, we can ensure that the machine you receive is in perfect condition and ready to be put into production, bringing you a quality service experience.

Packing machine for hookah coal package

After the shisha hookah charcoal production, you need a pillow packaging machine for round and cubic charcoal packaging. Then you can have good sales about hookah charcoal.

Round & cubic shisha charcoal tablet press machine

Shisha charcoal machine is for the efficient production of hookah…

Hydraulic shisha charcoal press machine

This kind of shisha charcoal press machine is to efficiently…

Round & cubic hookah shisha charcoal production line

Shuliy shisha charcoal production line is using wood waste, coconut…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually the pillow packaging machine,…

Shisha charcoal briquette production line sold to Indonesia

We're glad to share that one Indonesian client bought a…

How to make shisha charcoal?

In today's market, to make shisha charcoal (high-quality water-smoked charcoal)…

Shisha charcoal tablet press for square hookah production in Oman

The Omani client was committed to developing a hookah charcoal…

What’s the shisha charcoal making machine price?

In the market of hookah charcoal, the price of shisha…

How much does a hookah charcoal machine cost?

In recent years, many entrepreneurs and factories are considering investing…

Two solutions of shisha charcoal production from Shuliy

Shisha charcoal is very popular in the charcoal market. Do…

Hot Product

Compressed wood pallet machine

Compressed wood pallet machine is for manufacturing compressed…

Industrial hammer mill crusher for shredding wood

Wood hammer mill is for grinding wood branches,…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually pillow packaging…

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Small disc wood chipper for mass wood chips making

Disc wood chipper is designed to chip wood,…

Wood sawmill machine for log cutting

Wood sawmill machine is designed to process logs…