Charcoal briquette making machine for coal plant

Coal Briquette Machine | Charcoal Briquette Extruder Machine

Charcoal briquette making machine for coal plant

Coal Briquette Machine | Charcoal Briquette Extruder Machine

Features at a Glance

Table of Contents

Charcoal briquette making machine is used to make shaped charcoal briquettes from coal powder as barbecue charcoal and fuel. It has a capacity of 500-1500kg/h.

Featuring high efficiency, customization and cost-effectiveness, our charcoal briquette press is very popular around the world, such as in Colombia, Indonesia, Senegal, Guatemala, Kenya, etc.

If you’re interested, welcome to contact us for more machine details!

What’s the charcoal briquette machine?

Shuliy charcoal briquette making machine is a kind of equipment used to produce coal sticks, whose raw materials include carbon powder, coal powder, cow dung, grass powder, culture bacteria and so on.

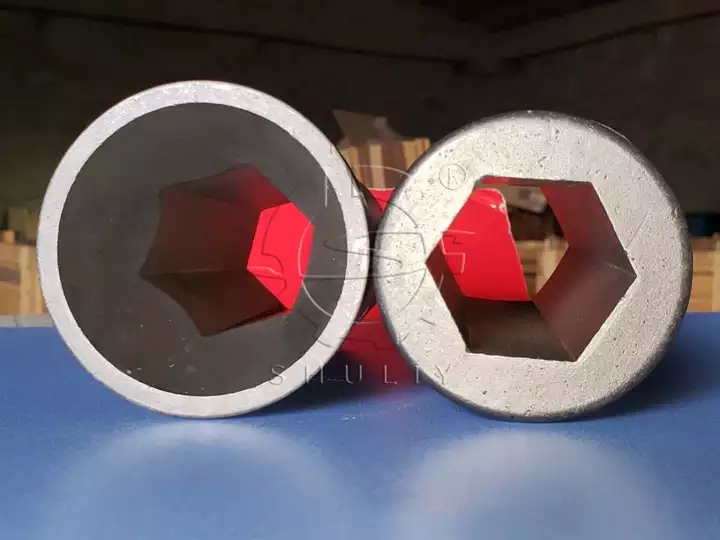

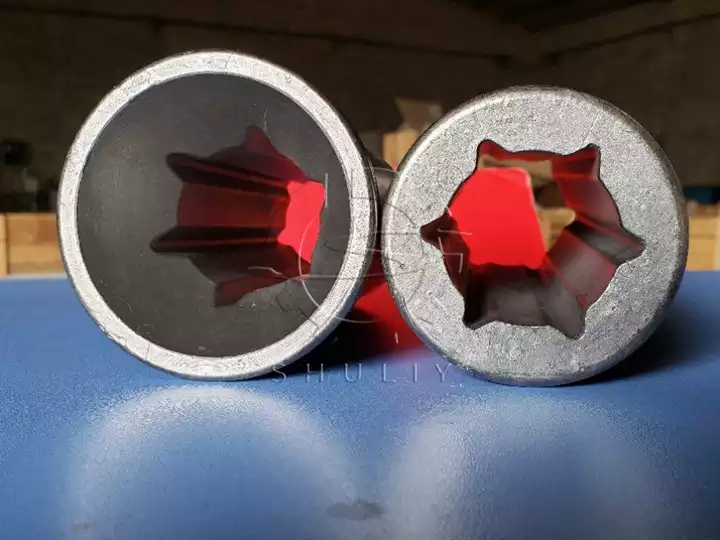

By mixing and processing these raw materials, the final product can be made with various shapes, such as hexagonal shape, quadrilateral shape, finger shape and so on.

These finished products in the shape of charcoal briquettes are widely used in areas such as barbecue stalls and fuels.

Highlights of Shuliy charcoal briquette machine

- Capacity of 500-1500kg/h: Shuliy charcoal briquette making machine can automate production, improve production efficiency and save time and labor costs.

- Variety of shape options: With different molds, the coconut charcoal briquette making machine can make a variety of shapes of coal bars to meet the needs of different customers and the diversity of the market.

- Environmentally friendly and sustainable: The charcoal briquettes making machine utilizes renewable resources such as carbon powder, coal powder, cow dung, grass powder and reduces the dependence on non-renewable resources such as natural wood, which is environmentally friendly and sustainable.

- Customized molds: Our charcoal briquette press machine can be customized with molds according to customers’ needs to meet personalized production requirements.

- Economical: The investment cost of the machine is relatively low, and the raw materials used in the production process cost less, which helps to reduce the production cost and increase the profit margin.

Technical parameters of Shuliy charcoal briquette making machine

| Model | Power(kw) | Capacity(kg/h) | Weight(kg) | Packing size(mm) |

| SL-160 | 11 | 500 | 850 | 2050*900*1250 |

| SL-180 | 18.5 | 1000-1500 | 1300 | 2500*1050*1100 |

How to make charcoal briquettes in different shapes?

The finished products of the charcoal briquettes making machine have various shapes, which vary according to different molds, including hexagonal, quadrilateral, rectangular and many other shapes.

Each shape has unique characteristics and uses. We also provide mold customization service to meet customers’ individual needs.

Whether it’s for a barbecue stand or a fuel field, we can produce the shape of the briquettes that meet the customer’s needs.

With the production of Shuliy charcoal extruder machine, you can get a variety of shapes of charcoal sticks to diversify your business and meet the needs of different scenarios.

Advantages of charcoal briquettes

Charcoal briquettes are widely used in the world. This briquette can be used not only in barbecue stalls as an ideal fuel, but also in a variety of combustion devices such as fireplaces, stoves, and wildlife stoves.

It is high calorific value, easy to burn, smoke-free and odorless, provides long-lasting heat, and is environmentally friendly, reducing the consumption of natural wood and other resources.

Structure of charcoal briquettes making machine

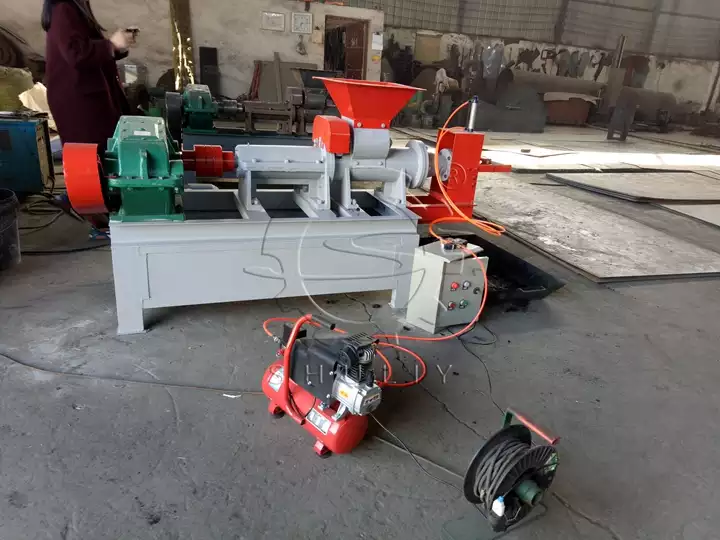

The structure of the sawdust charcoal briquette making machine mainly consists of feed inlet, motor, conveying screw, belt and cutter. If equipped with the cutter, the air compressor is necessary.

Working process of charcoal briquette extruder machine

The working process of Shuliy charcoal briquette making machine is very simple and efficient.

- Firstly, the raw materials such as carbon powder, coal powder, cow dung, grass powder, cultured bacteria, etc. are mixed well in a specific ratio.

- Next, the mixed raw materials are fed into the charcoal briquette extruder machine, and the machine will pressurize and shape the raw materials to form the desired shape of coal sticks.

- Finally, use the cutter to cut into the length you want, and the finished briquettes can be taken out for use or sale.

Three types of cutters for coconut charcoal briquettes machine

After the production of the charcoal press machine is completed, you can choose from three different cutting machines, including the automatic cutter, rolling cutter and meter counting cutter.

Automatic charcoal briquettes cutting machine for charcoal bars

This briquette cutting method is always used in charcoal bar making. The automatic cutter is controlled by an infrared sensor probe and can be adjusted to the desired length, cutting as short as 5 centimeters.

Normal size is usually 10-12 cm with a diameter of about 5 cm. And it always attaches to the charcoal briquette machine. At the outlet, a conveyor is used.

Rolling cutter for charcoal cubes

A rolling cutter is a special type of cutter, usually used in combination with an automatic cutter. During the cutting process, two cuts are actually made to ensure a more accurate and uniform result.

Because of the combination of the automatic cutter and the hobbing knife, the final product of the coal bar machine is lump coal.

Meter counting cutter for charcoal briquettes

The meter cutter is CNC controlled and can be flexibly adjusted from 3 to 40 cm, even down to 2.5 cm. This kind of charcoal cutting machine has several advantages:

- the length can be adjusted to meet different needs.

- the cutting process is less likely to be affected by ambient light and dust, ensuring the quality of the finished product.

- space can be saved during transportation; and the finished product has excellent results.

By choosing the appropriate charcoal cutting method, the charcoal briquette making machine can realize efficient cutting and meet various size requirements.

Either way, they offer flexibility and convenience, making the coal bar production process more efficient and reliable.

How about the charcoal briquette making machine price?

The price of a charcoal extruder machine can vary based on a number of factors, including machine model, production capacity, configuration options and brand.

In general, the smaller charcoal briquette making machine may cost between a few thousand and tens of thousands of dollars, while larger, high-capacity machines may cost tens of thousands of dollars or more.

In addition, special customized charcoal briquette press machine may have a higher price.

Shuliy machinery: credited charcoal briquettes machine manufacturer & supplier

As a professional charcoal briquette making machine manufacturer and supplier, Shuliy Machinery has won the trust and praise of customers.

With years of experience and technical strength, we are dedicated to the research, development, design and manufacture of charcoal machines.

Shuliy Machinery’s charcoal briquette making machine is widely recognized for its advantages of high-efficiency production, diversified shapes and environmental sustainability.

Focusing on product quality and performance, we use advanced production processes and high-quality materials to ensure the stability and reliability of each coal bar machine.

In addition, we provide customized services to make molds according to customers’ needs to meet the demand for coal rods of different shapes and sizes.

Besides, we also have wheel mixer grinder, sawdust briquette press, drying machine, etc.

Therefore, if you are interested in this coal bar machine, contact us now and our professional sales team will provide the best solution for you!

Successful cases of charcoal briquette making machine for sale

Our products have been successfully exported to many countries and are popular in both domestic and overseas markets. Such as Indonesia, the Philippines, Kenya, Nigeria and so on.

We will provide customers with specialized solutions to help them produce coal briquettes first. And before transportation, we will pack the machine in wooden crates and deliver it to the destination.

FAQ of Shuliy charcoal making machine

Is the final shape of the charcoal briquettes replaceable?

Yes, just replace the mold of Shuliy charcoal briquette making machine.

How many laborers are needed to operate the charcoal machine?

2 people.

Are the adhesives required? What are the adhesives? What is the function?

The local starch then acts as a binder, which makes the charcoal stronger and less prone to damage, allowing the charcoal to burn longer and burn fully.

How to make the best charcoal?

Charcoal powder fineness and binder.

How long does it take to produce the mold?

7-10 days.

Can I adjust the speed of the cutter?

The cutter is an inductive system that adjusts the speed according to the length of the final charcoal.

How to adjust the length of the final charcoal?

There are three holes on the cutter to adjust the length.

Charcoal briquette production line

Charcoal briquette production line is used to convert raw materials…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

Shuliy charcoal dryer machine is drying equipment that quickly dries…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually a heat shrink film…

500kg/h charcoal briquettes machine for sale to Brazil

Congratulations! Our Brazilian client ordered 2 sets of charcoal briquettes…

Export SL-140 charcoal briquette press machine to Kenya

Recently, a customer from Kenya ordered an SL-140 charcoal briquette…

1-3t/d biomass charcoal production line sold to Myanmar

Breaking news to Shuliy! One client from Myanmar bought a…

Charcoal briquette maker converts surplus coal in Guatemala

In Guatemala, a local entrepreneur looking for an innovative way…

Export of charcoal drying machine to Libya

Recently, one of our customers in Libya purchased the charcoal…

Senegal client chose Shuliy charcoal extruder machine for expansion

In Senegal, a forward-thinking customer was looking for a charcoal…

20 sets of charcoal briquette extruder machines sent to Indonesia

In 2023, 20 sets of Shuliy charcoal briquette extruder machines…

Hot Product

Drum wood chipper machine for chips production

Drum wood chipper machine is designed to chip…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to…

Sawdust briquette machine for Pini Kay briquettes making

Sawdust briquette machine is to press wood chips,…

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…

Industrial hammer mill crusher for shredding wood

Wood hammer mill is for grinding wood branches,…

Compressed wood pallet machine

Compressed wood pallet machine is for manufacturing compressed…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…