Round & cubic shisha charcoal tablet press machine

Hookah Charcoal Machine | Charcoal Making Machine

Round & cubic shisha charcoal tablet press machine

Hookah Charcoal Machine | Charcoal Making Machine

Features at a Glance

Table of Contents

Shisha charcoal machine is for the efficient production of hookah charcoal, made of stainless steel, which is corrosion and abrasion-resistant to ensure the stability and life of the machine.

Hookah charcoal is an environmentally friendly fuel commonly used for barbecue and heating, and is popular for its high calorific value and low ash content.

Shuliy stainless steel hookah charcoal machine can process raw materials such as carbon powder and coconut shell charcoal into regular hookah charcoal through a specific process, which is widely used in barbecue stalls, home heating and industry.

What’s the shisha charcoal?

Shisha charcoal is an environmentally friendly fuel made from natural raw materials such as carbon powder and coconut shell charcoal. Usually, the shapes are cubic and round. Coconut shell charcoal has a high calorific value and low ash content, making it an efficient energy choice.

Hookah charcoal burns with less smoke and fire, and can be used not only in the food and beverage industry such as barbecue stalls and hot pot restaurants, but also for heating and other domestic and industrial applications.

Through the processing of stainless steel shisha charcoal machine, the hookah charcoal has a regular shape and high density, which is easy to carry and use.

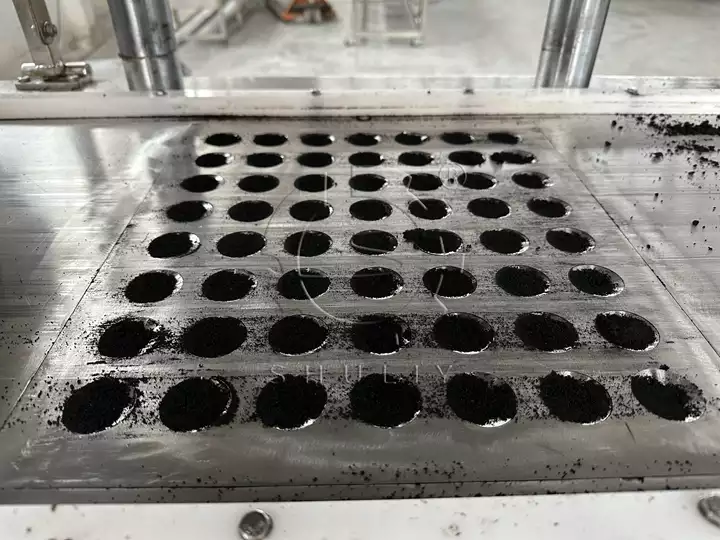

Moulds for stainless steel shisha charcoal press machine

- The mold of the stainless steel shisha charcoal machine is the tool used to form the hookah charcoal.

- The shape of the mold can be square or round, according to the customer’s demand.

- The design and manufacture of the mold are very critical and directly affect the shape and quality of the finished charcoal product.

Shuliy Machinery offers customizable mold options to meet the unique needs of different customers, ensuring the production of high-quality shisha charcoal products that meet standards and specifications.

Highlights of Shuliy shisha charcoal making machine

- It is made of stainless steel to ensure the corrosion resistance and life of the equipment.

- Through the process, the finished product of the shisha charcoal tablet press machine has regular shapes, high density and high combustion efficiency.

- As an environmentally friendly fuel, hookah charcoal produces less smoke when burned, which is harmless to the environment and health.

- The production process of stainless steel shisha charcoal machine is highly efficient, saving time and cost, and at the same time improving the output and quality of hookah charcoal.

Technical parameters of Shuliy shisha charcoal machine for sale

Our shisha charcoal tablet press machine is available in 80 tons and 100 tons pressures, with an operating voltage of 380V and a power of 13kw. It weighs 1000kg and has dimensions of 2500mm x 750mm x 2300mm.

The machine can produce various shapes and sizes of coal as shown below:

| Size of the molds | Number of punching once | Number of punches per minute |

| 2cm*2cm*2cm cube | 90 | 3 |

| 2.5cm*2.5cm*2.5cm cube | 80 | 3 |

| 3cm round | 72 | 3 |

| 3.3cm round | 56 | 3 |

| 4cm round | 42 | 3 |

How does the shisha charcoal machine work?

The working process of the stainless steel hookah charcoal making machine is simple and efficient.

- Firstly, raw materials such as carbon powder and coconut shell charcoal are put into the hopper.

- Then, the raw material is pressed uniformly into the upper and lower molds by means of a pushing mechanism.

- Next, through the action of molding machinery, the raw materials are pressed into the desired shape of hookah charcoal in the mold.

- Finally, the lower mold ejects the molded hookah charcoal. The pushing machine will push the shisha charcoal to the tablet.

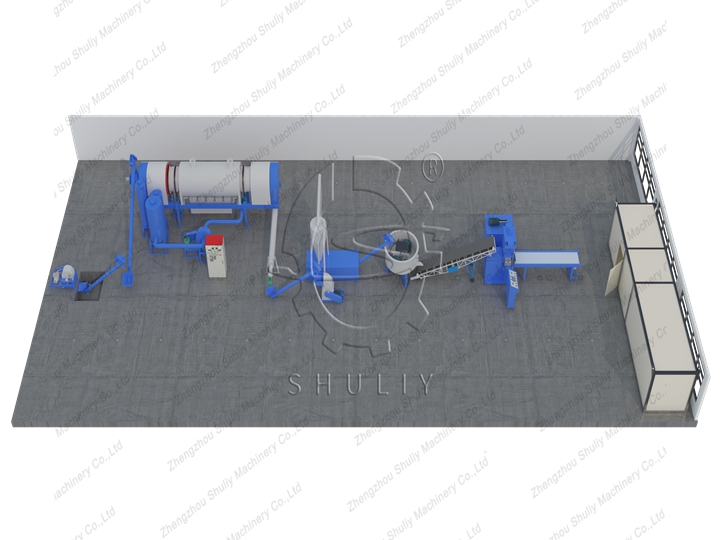

Matched equipment for hookah charcoal machine

Charcoal powder grinding and mixing machine

Before using the shisha charcoal machine, use the wheel mill to mix the raw material carbon powder core worker fully, the produced hookah charcoal density is bigger and the use effect is better.

Popular countries for shisha charcoal tablet press machine

Shuliy’s hookah charcoal tablet press machine is often exported overseas and is very popular in the international market, such as Brazil, Kenya, Nigeria, Indonesia and so on.

Package and delivery of Shuliy shisha charcoal machine

The stainless steel shisha charcoal machine is packed before delivery to the customer’s destination to ensure the safety of the machine during transportation. In addition, it also ensures that the machine is in good condition when the customer receives it.

Barbecue charcoal ball press machine

Shuliy charcoal ball press machine is a new type of…

Ship shisha charcoal making machine to Nigeria

We're so thrilled to share that one Nigerian client bought…

How to make rice husk charcoal?

Rice husk charcoal is a renewable and environmentally friendly energy…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to produce round…

Hydraulic shisha charcoal press machine

This kind of shisha charcoal press machine is to efficiently…

Round & cubic hookah shisha charcoal production line

Shuliy shisha charcoal production line is using wood waste, coconut…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually the pillow packaging machine,…

Shisha charcoal briquette production line sold to Indonesia

We're glad to share that one Indonesian client bought a…

How to make shisha charcoal?

In today's market, to make shisha charcoal (high-quality water-smoked charcoal)…

Shisha charcoal tablet press for square hookah production in Oman

The Omani client was committed to developing a hookah charcoal…

Hot Product

Flat die feed pellet machine for animal feed making

Feed pellet machine is designed to produce high-quality…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to…

Vertical wood peeling machine for tree debark removal

Wood peeling machine is designed to remove the…

Honeycomb briquette machine for coal pressing

Our honeycomb briquette machine is specialized equipment for…

Barbecue charcoal ball press machine

Shuliy charcoal ball press machine is for pressing…

Wood shaving machine for horse, chicken bedding

Wood shavings machine is designed to produce uniform…

Sawdust briquette machine for Pini Kay briquettes making

Sawdust briquette machine is to press wood chips,…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…