Coal briquettes processing plant for honeycomb charcoal

Coal briquettes processing plant for honeycomb charcoal

Features at a Glance

Table of Contents

Our honeycomb coal briquette production line is to efficiently produce high-quality honeycomb briquette products such as hexagonal shape, and brick shape by coal powder. This charcoal processing plant uses advanced technology and high-quality materials to ensure that you can consistently produce coal briquettes.

As a professional charcoal machine manufacturer and supplier, Shuliy can provide you with personalized solutions according to your needs. If you are interested, contact me for more information!

What’s the honeycomb coal briquette?

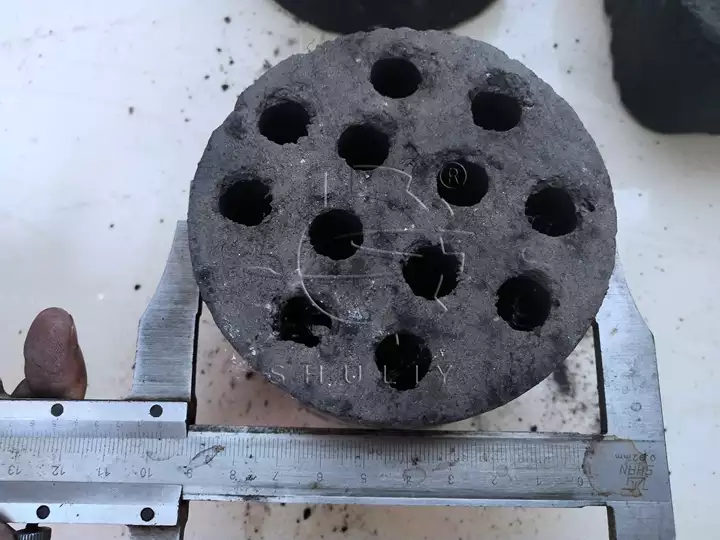

Honeycomb coal briquette, also known as honeycomb charcoal briquette, is a type of charcoal with a unique honeycomb structure. It is made by compressing finely ground coal or charcoal powder mixed with a binding agent into hexagonal or round shapes.

The unique honeycomb design provides good airflow during combustion, ensuring even and efficient combustion. Honeycomb coal briquettes are widely used as a clean and environmentally friendly fuel for a variety of heating and cooking applications. Their high heat output, long burn time and low ash content make them a popular choice for domestic and industrial use.

Machine used in the honeycomb coal briquette production line

For this charcoal making machine line, the flowchart to produce the honeycomb coal briquettes is carbonization furnace → charcoal grinding machine → charcoal mixing machine → Raymond mill → honeycomb coal press machine → drying machine → briquette package machine.

Carbonizing

Use the hoisting carboning furnace to convert raw biomass materials into charcoal through a controlled heating process, removing moisture and volatile substances.

Grinding

Charcoal produced from the carbonization furnace is relatively large. The charcoal grinding machine reduces the charcoal into smaller particles, improving its consistency and uniformity.

Blending and mixing

This device combines charcoal particles with binders and additives, ensuring a homogeneous mixture that enhances the briquette’s strength and quality.

Milling

Mixed charcoal is further processed in the Raymond mill to achieve finer particle sizes, resulting in a smoother and more cohesive mixture.

Briquetting

This honeycomb coal press machine shapes the charcoal mixture into honeycomb coal briquettes, applying high pressure to compact the material and create a characteristic hexagonal shape.

Drying

Freshly pressed honeycomb coal briquettes contain residual moisture. The drying machine reduces this moisture content, ensuring the briquettes are stable, durable, and ready for packaging.

Packaging

The final step involves packaging the dried honeycomb coal briquettes, making them ready for distribution and use.

Each machine in this honeycomb coal briquette production line contributes to turning raw biomass into high-quality honeycomb coal briquettes, which can be used for various heating and energy applications.

Features of honeycomb charcoal briquette production line

- Advanced technology. This honeycomb coal production line uses high technology and machinery to ensure efficient and continuous production.

- Customized coal sizes and shapes. Shuliy honeycomb coal briquette production line has various charcoal shapes to meet various market needs.

- High efficiency. It maximizes productivity by integrating various processes such as crushing, mixing and molding into one seamless workflow.

- Low energy consumption. This feature makes it an environmentally sustainable solution for honeycomb charcoal production.

Services about Shuliy honeycomb coal briquette production line

Shuliy honeycomb coal briquette production line offers a full range of services to meet the diverse needs of our customers. Such as professional consultation and guidance, customized solutions, installation, commissioning and operator training, and after-sales support.

All these are to ensure the long-term performance and reliability of the honeycomb coal production line, for your smooth use.

Coal briquette press machine for hexagonal, honeycomb, brick charcoal

In today's era of pursuing efficient energy utilization and environmental…

How to make honeycomb coal?

Honeycomb coal, a versatile biomass fuel, is rapidly gaining popularity…

Shuliy honeycomb briquette press helps Uzbekistan develop charcoal market

An energy company in Uzbekistan is facing strong demand for…

Hot Product

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Small disc wood chipper for mass wood chips making

Disc wood chipper is designed to chip wood,…

Roller log debarking machine for wood bark peeling

Log debarking machine is designed to efficiently and…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…

Hydraulic shisha charcoal press machine

This shisha charcoal press machine is to efficiently…

Batch-type dryer machine for brickets, honeycomb coal, hookah charcoal

This charcoal dryer machine is used to dry…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually heat shrink…