Roller log debarking machine for wood bark peeling

Debarker Machine | Log Peeling Machine

Roller log debarking machine for wood bark peeling

Debarker Machine | Log Peeling Machine

Features at a Glance

Table of Contents

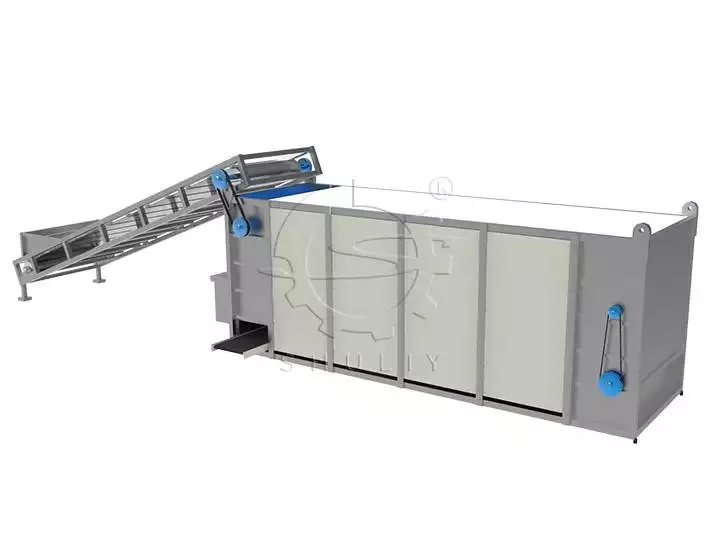

Log debarking machine is designed to efficiently and effectively remove bark from logs with features of high peeling rate, adjustable peeling thickness and easy operation.

It can remove tree bark from wood logs with dia. 50mm to 500mm and wood lengths from 2 to 6 meters. The machines exhibit high peeling rates of over 95%,

For increased efficiency, the wood log debarking machine can be integrated with other equipment such as grippers and conveyors to enable seamless and continuous processing of debarked woody material. This versatility makes wood debarkers suitable for a variety of wood processing applications.

Advantages of using log debarking machine

- Reduces waste: Peeling reduces wood waste by utilizing whole logs, making it a more sustainable and environmentally friendly process.

- Easy to operate: This kind of roller log debarker is designed with user-friendly features that make it easy to operate and maintain.

- Improving product quality: By removing the bark, the surface of the log is cleaned, resulting in the production of higher-quality lumber and wood products.

What kind of wood logs can be debarked?

Various types of logs, including trunks, branches and roots, up to 30 cm in diameter. The machine can debark these logs in batches, effectively removing the bark and producing a clean, smooth surface.

How does the wood log debarker machine work?

The log peeling machine works by feeding logs into the machine, which rotate and come into contact with sharp blades or teeth mounted on rotating rollers.

As the log rotates, the blades or teeth strip the bark from the surface of the log. The stripped bark is then separated from the log and discharged from the machine.

The debarked log exits the machine with a smooth, clean surface, ready for further processing or use.

Deliver the log peeling machine

Roller wood log debarker machines display

Technical specifications of wood log debarking machine

We offer a range of industrial wood debarker machines with different models and specifications to cater to various needs.

The models include SL-S500, SL-S600, SL-S700, and SL-S800, capable of handling wood diameters ranging from 50mm to 500mm and wood lengths from 2 to 6 meters. The machines exhibit high peeling rates of over 95%, ensuring efficient debarking.

The roller diameter, rotational speed, and length vary across the models to accommodate diverse wood processing requirements. With power ranging from 7.5 kW to 15 kW and weight ranging from 2.5 to 6 tons, the wood debarkers are designed for optimal performance and durability.

Their compact size and robust construction make them suitable for various industries and applications.

Vertical wood peeling machine for tree debark removal

Wood peeling machine is designed to remove the bark from…

SL-320 wood debarking machine for sale to Croatia

We're so excited to share that a Croatian client bought…

Ukrainian customer ordered wood log debarking machine

In Ukraine, a customer in the timber industry saw an…

Hot Product

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Continuous charcoal furnace for sale

Continuous carbonization furnace is specially used to convert…

Horizontal carbonization furnace for wood charcoal making

Horizontal carbonization furnace is used to convert wood…

Drum wood chipper machine for chips production

Drum wood chipper machine is designed to chip…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually heat shrink…

Industrial hammer mill crusher for shredding wood

Wood hammer mill is for grinding wood branches,…

Roller log debarking machine for wood bark peeling

Log debarking machine is designed to efficiently and…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…