Flat die feed pellet machine for animal feed making

Feed Pellet Mill | Feed Pelletizer Machine

Flat die feed pellet machine for animal feed making

Feed Pellet Mill | Feed Pelletizer Machine

Features at a Glance

Table of Contents

The feed pellet machine is designed to produce high-quality animal feed pellets, such as poultry, cattle, horse, rabbit, etc. The production capacity is 120-1200kg/h.

It efficiently processes raw materials such as grains, corn and soybean meal into uniform and nutritious pellets suitable for livestock.

Features of our feed pellet mill include advanced consistent pellet formation technology, adjustable pellet size and ease of operation.

Our feed pellet making machine’s benefits include enhanced animal nutrition, reduced feed waste, improved feed conversion, and ultimately, healthier animal growth and productivity.

This kind of animal feed pellet machine is very suitable for animal feed production. If you’re interested, welcome to contact us for more details!

Power available for feed pellet machine for sale

Our feed pellet machines for sale are available with electric motor and diesel engine power options.

- The electric motor option provides convenience and efficiency for indoor use.

- The diesel engine option provides flexibility for remote areas or areas with limited power supply.

This dual-power feature ensures continuous pellet production regardless of power availability. It allows you to select the most appropriate power option for their specific needs, making the feed pellet production process reliable and adaptable.

Features of animal feed pellet mill

- Adjustable size: The animal feed pellet mill can easily adjust the pellet size to meet the specific nutritional needs of different animals.

- Multipurpose: It is capable of processing a wide range of raw materials, including grains, grasses and by-products, ensuring flexibility in feed formulation.

- High efficiency: Cattle feed pellet machine is equipped with a powerful motor and precision engineering for high productivity and consistent pellet quality.

- Uniform mixing: The integrated mixing mechanism ensures uniform distribution of ingredients and prevents nutritional imbalances in the final feed pellet.

- Advanced mold technology: Innovative mold design ensures uniform compression and minimal wear, resulting in improved pellet durability.

- User-friendly controls: The modern control panel makes operation simple and allows easy adjustment and monitoring of the pelletizing process.

Working process of feed pelletizer machine

Material preparation

Gathering and preparing raw materials for the pelletizing process, such as grains, cereals, oilseeds and other ingredients.

Feed raw materials

Feed conditioned material into a feed pelletizer machine.

Form feed pellets

The raw materials are compressed through die-holes under high pressure and temperature. This process forms cylindrical feed pellets.

Cut feed pellets

The continuous extruded feed pellets will be cut into uniform lengths by rotating knives.

Discharge

The finished feed pellets come out from the outlet with the expected length.

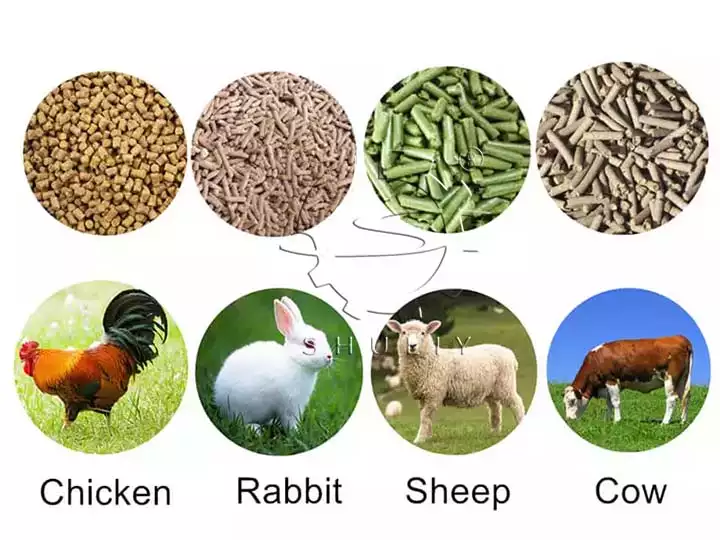

Animal feed produced by feed pellet mill

Our feed pellet machine produces high-quality pellets suitable for a wide variety of animals, including chickens, horses, cattle, sheep, rabbits, pigs and more.

These feed pellets are carefully formulated to meet the nutritional needs of each animal, providing essential vitamins, minerals and proteins for optimal growth and health.

Our feed pellets have consistent size and nutrition to ensure easy consumption and digestion for different animals.

Whether it’s poultry, livestock or pets, our pellets contribute to their health and overall performance, making them an important part of animal care and management.

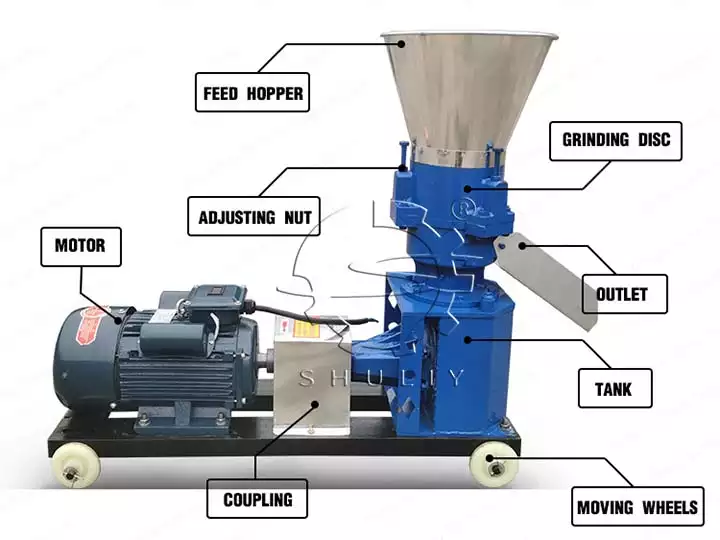

Composition of chicken feed pellet machine

This animal feed pellet mill machine consists of feed hopper, grinding disc, adjustable nut, motor(diesel engine), coupling, moving wheels, tank and outlet.

Small feed pellet production line for animal feed plant

Small feed pellet production line for animal feed mill is designed to be highly automated and efficient. It uses advanced technology and machinery to streamline the process of manufacturing feed pellets.

This intelligent production line includes hammer mill, mixer, pelletizer, cooler, packaging machine and other equipment.

This automation not only saves labor and time, but also ensures precise formulations, uniform mixing, and accurate pellet sizes to produce high-quality animal feed that meets nutritional requirements.

Why choose Shuliy as feed pellet machine supplier?

With years of industry experience, Shuliy offers advanced equipment that embodies advanced technology and innovation.

Our feed pellet machines are designed to meet the diverse needs of animal feed production and are backed by strong engineering and reliable performance.

Shuliy’s reputation as a trusted supplier is rooted in its dedication to customer satisfaction, as evidenced by superior product quality, timely support and a global network.

Successful cases of Shuliy feed pelletizer machine

Technical data of cattle feed pellet machine

Model: KL-120, KL-150, KL-210, KL-260, KL-300

Capacity: 120kg/h-1200kg/h

Power: electric motor or diesel engine

Mould Plate Diameter: 120mm, 150mm, 210mm, 260mm, 300mm

Finished products use: chicken feed, cattle feed, horse feed, rabbit feed, pig feed, goat feed, etc.

25 sets of feed pellet mills sold to Saudi Arabia

We're excited to share that one distributor from Saudi Arabia…

Hot Product

Hydraulic shisha charcoal press machine

This shisha charcoal press machine is to efficiently…

Small disc wood chipper for mass wood chips making

Disc wood chipper is designed to chip wood,…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…

Wood shaving machine for horse, chicken bedding

Wood shavings machine is designed to produce uniform…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Pillow packaging machine for shisha hookah charcoal pack

The shisha charcoal packing machine, actually pillow packaging…

Heat shrink film packaging machine for charcoal briquettes

The charcoal briquettes packing machine, actually heat shrink…