Raymond mill for charcoal powder grinding

Raymond Roller Mill | Charcoal Powder Grinding Machine

Raymond mill for charcoal powder grinding

Raymond Roller Mill | Charcoal Powder Grinding Machine

Features at a Glance

Table of Contents

Raymond mill is efficiently to crush and grind charcoal into 3-5mm fine particles for subsequent charcoal briquette making.

This Raymond coal mill has precise particle control, also can handle other materials such as ores and chemicals. It has a processing capacity of 0.5-40t per hour.

This charcoal powder grinding machine features an advanced gas separation system, efficient particle classification technology, as well as low energy consumption and low noise.

Its high-quality performance has made it exported to many countries around the world, serving many industrial fields.

Features of Raymond mill

- Grinding raw materials into 3-5mm: This machine can grind crushed charcoal into3-5mm, very fine, often used after coal crusher.

- Adjustable particle size: The final products are precise uniform fineness.

- Long service life and low maintenance: Its robust construction and reliable performance ensure long service life and minimal maintenance.

- Charcoal, chemicals, minerals grinding: Our charcoal powder grinding machine’s versatility in processing a wide range of materials, from minerals to chemicals, enhances its applicability to different industries.

- Reliable operation: The main transmission device of the grinding mill adopts a closed gearbox and pulley, which ensures stable transmission and reliable operation.

Technical data of Raymond roller mill

| Model | SL-500 | SL-650 | SL-780 | SL-980 | SL-1100 | SL-1450 | SL-1760 | SL-1950 | SL-2100 |

| Capacity(t/h) | 0.5-2 | 0.5-2.5 | 1-3 | 1.5-4 | 2-6 | 6-10 | 8-20 | 15-30 | 20-40 |

| Main engine motor power(kw) | 7.5 | 15 | 18.5 | 30 | 45 | 90 | 132 | 185 | 220 |

| Fan motor power(kw) | 5.5. | 11 | 15 | 22 | 45 | 100 | 160 | 185 | 220 |

| Analyzer motor power(kw) | 1.1 | 120 | 2.2 | 2.2 | 5.5 | 7.5 | 22 | 37 | 45 |

| Main shaft speed(r/m) | 120 | 120 | 120 | 120 | 120 | 90 | 90 | 90 | 90 |

| Diameter of Grinding ring(mm) | 500 | 650 | 780 | 980 | 1100 | 1450 | 1760 | 1950 | 2100 |

| Diameter of grinding roller(mm) | 150 | 180 | 260 | 300 | 320 | 400 | 450 | 570 | 630 |

| max.feed size(mm) | 15 | 15 | 15 | 20 | 25 | 30 | 30 | 40 | 40 |

| Weight(t) | 1.8 | 2.8 | 3.8 | 6.5 | 14.5 | 26 | 48 | 65 | 85 |

We have a variety of Raymond mill models for your reference, but it should be noted that when choosing a machine, you should pay attention to the matching with the entire charcoal production line.

Applications of Raymond mill

Raymond grinding mill is widely used for crushing and processing charcoal, minerals, chemicals, ores, such as coal, marble, limestone, calcite, dolomite, talc and other materials.

The machine is vital in mining, metallurgy, chemicals, building materials and other industries that require finely ground powders.

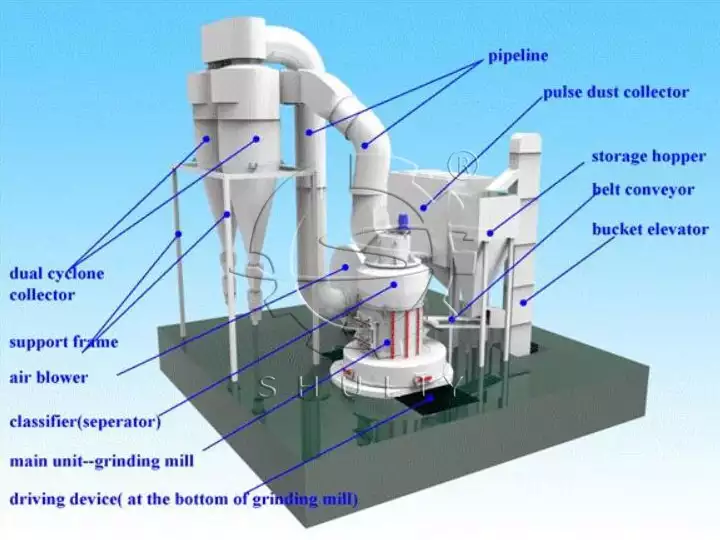

Construction of Raymond roller mill

From the above picture, you can know its components. If you have any questions, welcome to contact us for more details!

Raymond mill working principle

The coal crusher machine works by grinding material through the action of rotating rollers and grinding rings.

- The material is fed into the grinding chamber and the rollers exert a force on it, pressing it against the grinding rings.

- As the rollers rotate, they crush and grind the material, which is then carried by an air stream to a classifier for separation.

- Oversized particles are returned to the grinding chamber for further processing, while fine particles are collected and conveyed for final product output.

This process ensures efficient grinding and size reduction in the Raymond roller mill.

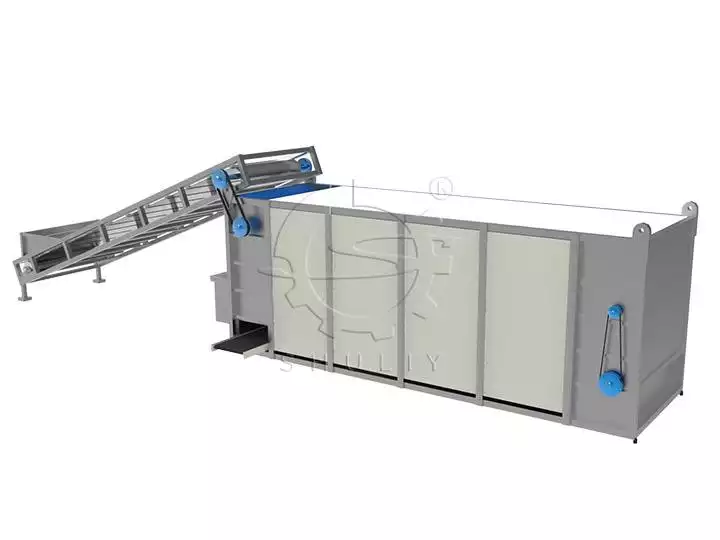

Charcoal powder grinding machine in the charcoal machine line

In the charcoal briquettes processing line, the Raymond roller mill finely crushes charcoal into uniform powder to increase its surface area for effective charcoal briquette making.

Its integration with the charcoal machine line simplifies the production process and improves overall efficiency.

The machine’s compact design and user-friendly operation make it an essential part of obtaining a high-quality charcoal product.

Powerful Raymond mill manufacturer

As a professional Raymond roller mill manufacturer, we have several significant advantages:

- High-quality materials and advanced manufacturing process: Our equipment has high durability and stability, ensuring long-term running.

- A full range of technical support and services: We have an experienced technical team, providing equipment installation, commissioning, daily maintenance, etc.

- Customized service: Regardless of different production scales or special material handling requirements, we can customize to meet your diverse needs.

- High-quality after-sales service: We provide regular maintenance, troubleshooting and technical training to ensure that customers have no worries during use.

- Competitive price: We are self-produced and self-sold, not only with superior performance, but also reasonable price, compared with other suppliers, with price advantages.

How to buy the Raymond grinding mill?

To purchase the Raymond mill, simply follow these steps:

- Contact Us: Reach us through our website, email, WhatsApp or phone to express your interest in buying the Raymond mill.

- Discuss Requirements: Our sales team will discuss your specific requirements, including capacity, fineness, and any customization needs.

- Quotation: We will provide you with a detailed quotation, including the price, specifications, and delivery time.

- Confirmation: Once you are satisfied with the quotation, confirm your order by making the necessary payment.

- Production and Delivery: We will start production according to your order and deliver the Raymond mill to your designated location.

- Installation and Training: Our technical team can assist with installation and provide training on operating and maintaining the mill.

- After-Sales Support: We offer comprehensive after-sales support for any inquiries, maintenance, or troubleshooting.

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer (also known as wheel mill, charcoal mixer…

Hammer mill for charcoal coal grinding

The charcoal grinder machine is a multi-functional machine that can…

Role of charcoal powder grinding machine in coal production

The charcoal powder grinding machine, also known as wheel grinder…

Hot Product

Compressed wood pallet machine

Compressed wood pallet machine is for manufacturing compressed…

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Industrial pallet crushing machine for sale

Waste wood crusher machine is designed for processing…

Industrial wood shredder machine for sawdust making

Wood crusher machine is specialized in shredding wood…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to…

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…

Quantitative BBQ charcoal packing machine

BBQ charcoal packaging machine is used to package…

Continuous drying machine for BBQ charcoal

The briquette dryer machine is used for BBQ…

Small disc wood chipper for mass wood chips making

Disc wood chipper is designed to chip wood,…