Wood sawmill machine for log cutting

Saw Mill Machine | Bandsaw Lumber Mill

Wood sawmill machine for log cutting

Saw Mill Machine | Bandsaw Lumber Mill

Features at a Glance

Table of Contents

Wood sawmill machine is a versatile machine designed to process logs into lumber, making it an essential tool for the woodworking industry. It can handle wood diameters of 30-250cm.

There are three main types of lumber sawmills: log sliding table sawmill, vertical bandsaw mill, and horizontal lumber mill.

All three machines can efficiently convert logs into various sizes of lumber, making them suitable for construction, furniture making and other woodworking projects.

Its ability to process different types, sizes and shapes of wood makes it an important tool for the wood industry.

Type 1: Sliding wood sawmill machine

The wood log sliding table saw is designed to process various types of wood materials, including raw logs, lumber sections, and timber with a diameter of up to 50cm.

It’s an ideal choice for smaller woodworking factories aiming to transform these materials into usable wood boards.

With its sliding mechanism, this sawmill machine offers precision and control during the cutting process, ensuring accurate dimensions and smooth finishes on the final wood products.

Its efficiency and versatility make it an essential tool for smaller-scale operations seeking to produce quality wood boards for construction, furniture, and other applications.

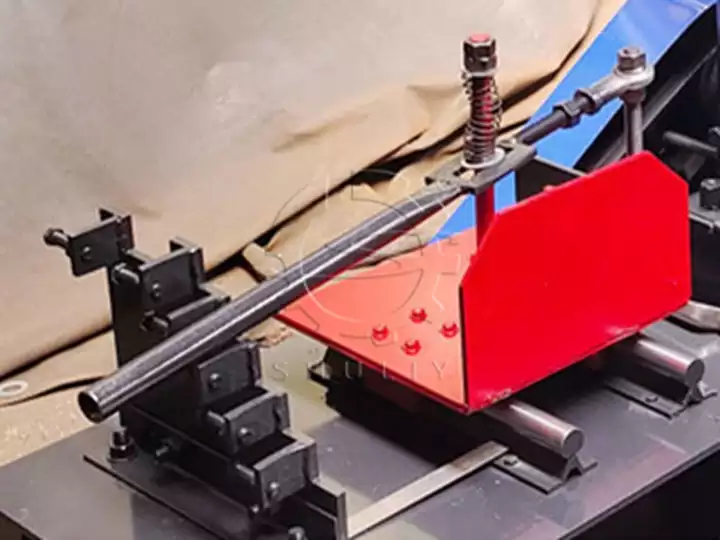

Structure of wood sawmill machine

- Control cabinet: Control of electrical equipment for operation and control.

- Saw blades: Used to cut wood for an efficient cutting process.

- Fixing logs device: Fixes the logs to ensure stability during the cutting process.

- Stopper: Controls the thickness of the wood with the help of the carriage.

- Carriage: Carrying device to transport the wood to the cutting area for automated cutting.

Features of log sawmill machine

- High efficiency: Lumber mill can process a large number of round logs quickly and efficiently, reducing the time and labor for manual operation.

- Strong applicability: Wood sawmill machine can process various tree species, including softwood and hardwood, and at the same time can flexibly adapt to different diameters, lengths and shapes.

- High cutting accuracy: The machine design and operation enable it to accurately cut large pieces of wood while maintaining the required size and flatness.

- Good reliability: Our saw mill machine has a sturdy structure and durable components, which usually have a long service life and low maintenance cost.

Technical parameters of sawmill machine

SL-300: Suitable for cutting wood with a maximum sawing length of 4000mm and a maximum sawing diameter of 300mm, equipped with twin 7.5kW motors, with a body size of 8000*1600*1600mm and a weight of 750kg.

SL-400: Applicable for cutting wood with a maximum sawing length of 4000mm and a maximum sawing diameter of 400mm, equipped with two motors of 11kW and 7.5kW, with a body size of 8000*1600*1600mm and a weight of 750kg.

SL-500: Designed for sawing wood with a maximum length of 4000mm and a maximum diameter of 500mm, equipped with two 11kW motors, with a body size of 8000*1600*1600mm and a weight of 750kg.

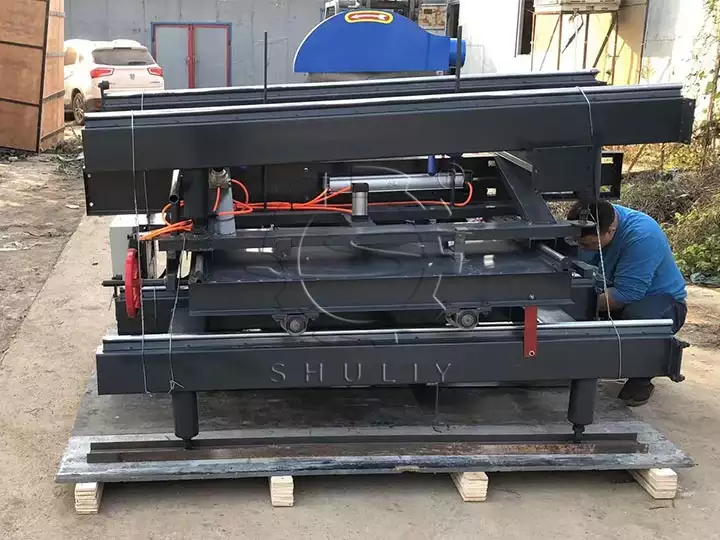

Export the bandsaw lumber mill to Monaco

We proudly export our high-quality bandsaw lumber mill to Monaco, delivering efficient wood cutting and processing solutions that meet the demands of your woodworking projects.

Our wood sawmill machine ensures precision and productivity, making it a valuable addition to your operations.

Type 2: Vertical bandsaw mill

The vertical wood sawmill machine is ideal for processing logs, wood sections, and squared timber with a maximum diameter of 80cm to 100cm.

It efficiently transforms raw materials into valuable wood products, offering versatility for various woodworking needs.

Components of vertical bandsaw lumber mill

This kind of wood sawmill machine consists of basic components such as the saw blade, upper and lower wheels for blade movement, and a control panel for adjusting cutting parameters.

These components work in coordination to ensure precise and efficient wood cutting operations. The machine is capable of adjusting settings and controlling processes to provide versatility and accuracy for a variety of woodworking tasks.

Advantages of wood sawmill machine for sale

- It can realize high-precision cutting of wood, which can ensure precision of wood cutting, can save processing time and improve processing efficiency;

- The wood sawmill machine can realize a variety of cutting, can adjust the angle and depth of cutting according to the actual demand, and can realize a variety of cutting of wood, such as straight line cutting, curve cutting, bending cutting and so on;

- Its simple structure, easy use and safe operation can reduce the risk of woodworking processing and improve the safety of woodworking processing.

Technical data of automatic saw mill machine

SL-3000: With a saw wheel diameter of 1600 mm, the SL-3000 is capable of handling timber up to 800 mm in diameter. It is equipped with a 30KW motor, CNC saw thickness setting and motorized timber clamping model. The maximum sawn timber length is 4000 mm.

SL-5000: With a saw wheel diameter of 1250 mm, the SL-5000 can accommodate larger maximum timber diameters of 1000 mm. Equipped with a more powerful 45 KW motor, it also offers CNC saw thickness setting and a hydraulic timber clamping model. Its maximum sawn timber length is extended to 6000 mm.

Send vertical bandsaw mill machine to Papua Guinea

We can certainly arrange to send the vertical bandsaw mill machine to Papua Guinea. Our efficient shipping and delivery process ensures that your equipment will reach you safely and on time.

Whether it’s for personal or industrial use, our wood sawmill machine is designed to provide accurate and efficient wood cutting solutions. Feel free to contact us for more details on the shipment and delivery process.

Working video of the vertical band sawmill

Type 3: Horizontal bandsaw lumber mill

The horizontal wood sawmill machine is designed for processing large logs, timber sections, and square blocks, accommodating diameters ranging from 150cm to 250cm.

This lumber mill is suitable for industrial-scale operations, it’s ideal for sawing and producing boards.

This machine is commonly used in larger woodworking facilities and offers the capability to process substantial wood sizes efficiently.

Whether for domestic sales or export, it ensures effective wood processing for a variety of applications.

Highlights of horizontal wood sawmill machine

- High capacity: Horizontal wood sawmill machines are designed for large-scale operations, capable of processing substantial volumes of timber.

- Wide diameter range: These machines can handle logs and lumber with diameters ranging from 150cm to 250cm, making them versatile for various wood sizes.

- Hydraulic wood clamping: The hydraulic wood clamping system ensures secure positioning of the wood during cutting, enhancing safety and accuracy.

- CNC sawing thickness setting: The CNC-controlled sawing thickness setting allows for easy customization and precision in achieving desired wood dimensions.

- Powerful motor: With motor power ranging from 30KW to 45KW, these machines deliver strong cutting performance for various wood types.

Technical specifications of lumber mill

Model: SL-1500

Saw wheel diameter: 1000mm

Maximum sawing wood diameter: 1500mm

Motor power: 37KW

Thickness adjustment: Maximum 350mm

Max. cutting length: 6000mm

Weight: 4500kg

Model: SL-2500

Saw wheel diameter: 1070mm

Maximum sawing diameter of wood: 2500mm

Motor power: 55KW

Thickness adjustment: Max. 450mm

Max. cutting length: 6000mm

Weight: 5500kg

Working video of horizontal sawmill machine

Applicable areas of wood sawmill machine

Timber sawmills are widely used in various fields. They are essential for processing logs, timber profiles and blocks into usable lumber for construction, furniture production and woodworking projects.

With the ability to handle different types and sizes of wood, these machines are essential for sawing operations in sawmills, woodworking stores and the woodworking industry.

Do you know the wood sawmill machine price?

Factors such as model, size, features and supplier will all have an impact on sawmill prices.

As a professional wood processing machine manufacturer and supplier, we have different types of lumber mills for your reference, And we can offer a competitive price to you.

If you’re interested, get in touch with us for mroe details!

Contact me for more about saw mill machine!

Also, we have wood crusher, wood shaving machine, etc. available for sale.

Feel free to reach out for further information about our sawmill machines! We’re here to assist you in finding the right solution for your lumber processing needs.

UAE customer buys SL-600 log sliding table saw

The UAE customer is a newly established wood processing company…

Hot Product

Horizontal carbonization furnace for wood charcoal making

Horizontal carbonization furnace is used to convert wood…

Drum wood chipper machine for chips production

Drum wood chipper machine is designed to chip…

Honeycomb briquette machine for coal pressing

Our honeycomb briquette machine is specialized equipment for…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Round & cubic shisha charcoal tablet press machine

This shisha charcoal machine is for the efficient…

Hoist charcoal furnace for wood logs, bamboo coal

Hoist carbonization furnace is capable of carbonizing logs,…

Rotary drum dryer machine for sawdust, rice husks

The rotary dryer machine is to dry various…

Industrial pallet crushing machine for sale

Waste wood crusher machine is designed for processing…

Rotary hookah charcoal machine for round & cubic shisha charcoal

The rotary hookah charcoal machine is especially to…