Honeycomb coal briquette production line

Honeycomb coal briquette production line

Features at a Glance

Table of Contents

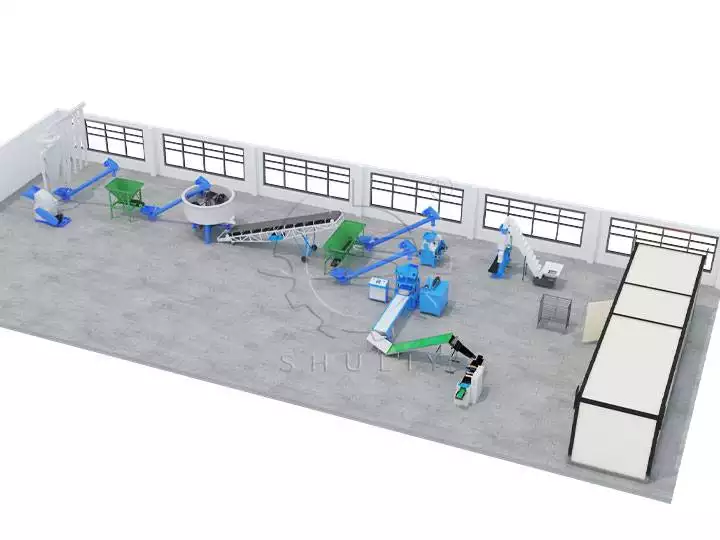

Our honeycomb coal briquette production line is to automatically make honeycomb or hexagonal coal from coal powder or charcoal powder. This plant mainly includes carbonizing, charcoal crushing, charcoal powder mixing, and briquetting.

Through the above process, the honeycomb coal produced has high density, long-lasting combustion and low pollution. This charcoal processing plant has a capacity of 500kg/h, 1t/h, etc. We can flexibly customize solutions according to your needs.

Are you interested? If yes, please contact us now! We will provide the most suitable solution to meet your charcoal business needs.

Steps of honeycomb coal briquette production

As a professional charcoal machine producer and manufacturer, our honeycomb coal briquette production line is fully automatic and efficient. Its steps include carbonizing→charcoal crushing→charcoal powder grinding mixing→briquetting→drying→packing.

Now, let’s introduce each process and the equipment used one by one.

Step 1: carbonizing

The first step is to carbonize the raw materials.

You can refer to the following to choose the suitable carbonization furnace.

- Wood logs, branches, bamboo, etc.: hoisting carboning furnace or horizontal charcoal furnace

- Coconut shell, rice hull and others: continuous charcoal machine

Step 2: charcoal crushing

Charcoal produced from the carbonization furnace is relatively large.

You need a hammer mill to crush charcoal into 5-10mm size.

Step 3: charcoal powder grinding and mixing

For making quality charcoal briquette, you need finer charcoal powder and mix the binder with it.

At this point, you need a wheel grinder mixer to help you.

Step 4: charcoal powder briquetting

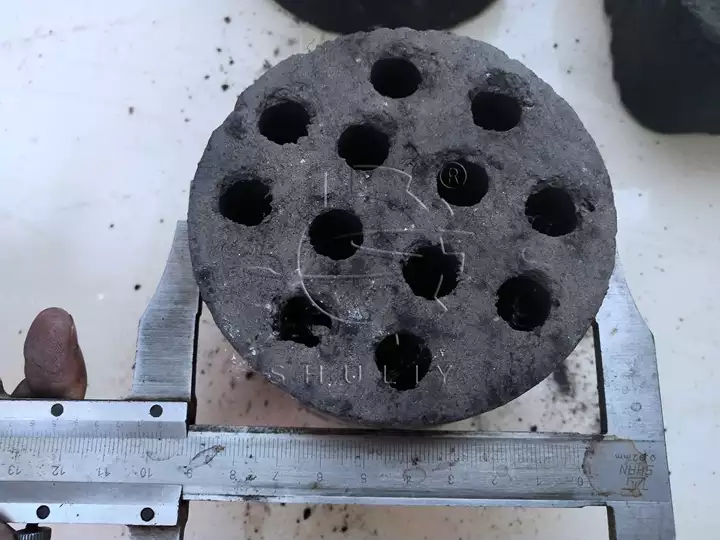

After getting the suitable charcoal powder, the honeycomb coal press machine shapes the charcoal mixture into coal briquettes.

You can make different coal briquettes by changing molds.

Step 5: coal briquettes drying

Then, you need a drying machine, because freshly pressed honeycomb coal briquettes contain residual moisture.

The machine can reduce the moisture content, ensuring the briquettes are stable, durable, and ready for packaging.

Step 6: honeycomb briquettes packing

Finally, package the honeycomb coal briquettes with a heat shrink film packing machine.

After packing, it’s good for delivery and sale.

Features of honeycomb coal briquette production line

- It has an output of 500kg/h, 1t/h, etc., which is highly efficient.

- This honeycomb charcoal making line has a high degree of automation. 3-4 laborers can operate this line to run smoothly.

- We can flexibly configure the charcoal production line to benefit your charcoal business. For example,

- Carbonizing→charcoal crushing→briquetting

- Charcoal powder grinding mixing→briquetting

- Charcoal crushing→briquetting→drying

- We can customize coal sizes and shapes by changing molds to meet your demands.

Services you can enjoy on Shuliy honeycomb coal production line

Shuliy honeycomb coal briquette production line provides a full range of services to meet your diversified needs. Such as,

- Professional consulting guidance

- Customized solutions

- Installation

- Commissioning

- Operator training

- After-sales support

All these are designed to ensure the long-term performance and reliability of the honeycomb briquette production line for your smooth use.

How about the honeycomb briqutting plant price?

The price of a honeycomb coal briquette machine line is affected by many factors, so there is no fixed price. The factors affecting the price mainly include:

- Capacity: the larger the capacity, the more complex the equipment, and the higher the price.

- Automation: the higher the degree of automation, the higher the price.

- Configuration: supporting equipment (such as dryers, conveyors, etc.) how much and type will affect the price.

- Brand: the price of equipment of well-known brands is usually higher.

- Market conditions: market supply and demand, raw material prices and other factors will also affect the price of equipment.

If you want to know a more accurate price, we suggest you provide the following information:

- What is your daily production requirement?

- How automated do you want the equipment to be?

- Do you have a brand preference?

Tips on choosing honeycomb coal briquette plant

Choosing the honeycomb coal molding plant is a systematic project, which requires comprehensive consideration of various factors. Here are some suggestions:

- Capacity demand

- Nature of raw materials

- Final product specification

- Degree of automation

- Floor space

If you want to know more about the honeycomb coal briquette production line, please feel free to inquire! We will provide you with customized solutions according to your actual situation.

Honeycomb briquette machine for coal pressing

Our honeycomb briquette machine is specialized equipment for producing honeycomb…

How to make honeycomb coal?

Honeycomb coal, a versatile biomass fuel, is rapidly gaining popularity…

Shuliy honeycomb briquette press helps Uzbekistan develop charcoal market

An energy company in Uzbekistan is facing strong demand for…

Hot Product

Hammer mill for charcoal coal grinding

Charcoal grinder machine can crush a variety of…

Hydraulic shisha charcoal press machine

This shisha charcoal press machine is to efficiently…

Industrial pallet crushing machine for sale

Waste wood crusher machine is designed for processing…

Roller log debarking machine for wood bark peeling

Log debarking machine is designed to efficiently and…

Compressed wood pallet machine

Compressed wood pallet machine is for manufacturing compressed…

Quantitative BBQ charcoal packing machine

BBQ charcoal packaging machine is used to package…

Vertical wood peeling machine for tree debark removal

Wood peeling machine is designed to remove the…

Wheel mill for charcoal powder grinding and mixing

Charcoal powder mixer is used for mixing and…

Charcoal machine for coconut shell charcoal manufacturing

Coconut shell charcoal making machine is designed to…