Two solutions of shisha charcoal production from Shuliy

Table of Contents

Shisha charcoal is very popular in the charcoal market. Do you know which methods can be used for producing hookah charcoal? The following two methods are introduced for your reference.

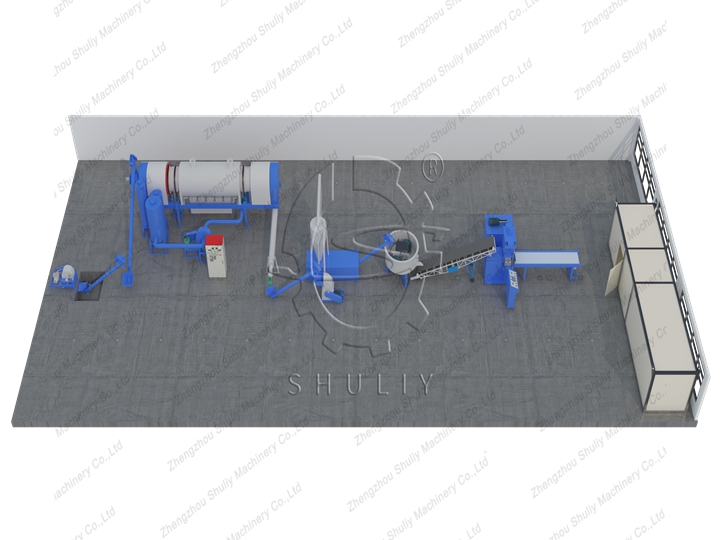

Method 1: Charcoal powder pressing and molding method(main process)

Applicable raw materials: charcoal powder, coconut shell charcoal powder, sawdust charcoal powder and so on.

Main process of shisha charcoal making:

- Crushing: crush the charcoal block into charcoal powder suitable for charcoal molding.

- Mixing: add binders into charcoal powder and mix well.

- Pressing: use the shisha hookah charcoal pressing machine to press the material into standard shapes such as round pieces, cubic pieces, and so on.

- Drying: dry naturally or at a low temperature to keep the hardness and shape.

- Packing: quantitatively packed into boxes, can be printed with a LOGO for export.

Features: Uniform shape, high density, stable combustion, suitable for the Middle East market.

Shuliy can provide a full set of production line and customized mold services.

Method 2: Charcoal stick slicing method (traditional low cost)

Applicable raw materials: coal powder, coconut shell powder, etc.

Main process of shisha charcoal production:

- Rod making: make hexagonal charcoal rods using a charcoal briquette-making machine.

- Cutting: cut the charcoal stick into short pieces with a cutter.

- Drying & packing: after drying, it can be packed and used directly.

Characteristics: simple process, low cost and suitable for the start-up stage. But the appearance and density consistency are slightly poor, suitable for the local hookah market.

Want to carry out hookah charcoal production? Come to contact us. We will help you to start your shisha charcoal processing business efficiently according to your raw materials, finished product requirements, budget and so on.